Module III – Choosing the right maintenance strategy for your fleet

On the road to fleet health, implement a maintenance strategy that lets you spot issues around the bend. Are you still reacting to bumps in the road instead of anticipating them?

Choosing the best maintenance strategy for your fleet will hinge on your agency’s priorities. Whether you opt for a preventative approach or implement a predictive maintenance program, both options can boost efficiency, save money and extend the lifespans of your vehicles.

Which maintenance strategy is the best fit for your fleet?

Different maintenance strategies offer varying approaches to upkeep and repair, each with their own benefits and drawbacks. The choice of maintenance strategy can depend on various factors, such as the type of vehicle, its criticality, the operating environment and budget constraints. Many organizations adopt a combination of strategies to optimize their maintenance operations.

3 most commonly adopted maintenance strategies

Reactive maintenance

This approach involves addressing issues only after they occur. It's often referred to as "run-to-failure" maintenance, as it waits for equipment to fail before action is taken.

Preventative maintenance

This strategy focuses on scheduled maintenance tasks aimed at preventing vehicle failure and helping extend the lifespan of the vehicle. It includes maintenance activity such as regular inspections, servicing and component replacements based on time, usage or other predetermined factors.

Predictive maintenance

This strategy uses data analysis and monitoring to predict when equipment is likely to fail. By identifying potential issues in advance, maintenance can be scheduled proactively, helping reduce downtime and optimize performance.

Less common maintenance strategies

Corrective maintenance

Similar to reactive maintenance in that it focuses on repairing or restoring vehicles after a failure or breakdown has occurred, this type of maintenance is more proactive as it aims to identify the root cause of the failure and prevent it from happening again.

Condition-based maintenance (CBM)

CBM focuses on monitoring the actual condition of equipment through sensors and data analysis. Maintenance is performed only when specific conditions or indicators suggest that it is necessary.

Reliability-centered maintenance (RCM)

RCM is a comprehensive approach that prioritizes maintenance tasks based on their impact on vehicle reliability and safety. It involves analyzing failure modes, their consequences and the most effective maintenance strategies to prevent them.

Total productive maintenance (TPM)

TPM is a holistic approach that involves all employees in the maintenance process. It aims to maximize equipment effectiveness by combining preventive maintenance, continuous improvement and employee involvement.

Did you know?

In 2023, repair costs jumped by as much as 20% during the first half of the year in some fleet industry segments. In 2024, vehicle repair costs increased by nearly 12% over the year leading up to April 2024, which is more than triple the overall inflation rate.

Understanding the nuances

For the purpose of this module, we will focus on the three most common fleet maintenance strategies.

Before diving into each, we have simplified and illustrated the effect that each strategy can have on your budget (with total cost being the sum of repair costs and preventative maintenance costs). This will be particularly helpful in understanding the nuances between preventative and predictive maintenance and ultimately help you determine where each may fit into your operations.

What is reactive maintenance?

Reactive maintenance is a maintenance strategy that involves addressing equipment issues only after they occur. It's often referred to as a "run-to-failure" approach, as it waits for equipment to fail before taking any action. This approach is common in situations where the cost of downtime is low or the consequences of failure are not severe. However, it can lead to unexpected breakdowns, increased downtime and potentially higher repair costs in the long run.

Pros of reactive maintenance

- Lower upfront costs: Reactive maintenance requires minimal investment in planning, monitoring or preventive measures.

- Reduced administrative overhead: There's no need for complex scheduling, data analysis or predictive modeling.

- Simplicity: This approach is straightforward to implement, requiring minimal expertise or specialized tools.

Cons of reactive maintenance

- Increased downtime: Unexpected breakdowns can lead to significant downtime, impacting productivity and efficiency.

- Higher repair costs: Neglecting preventive measures can lead to more severe damage and potentially higher repair costs.

- Safety risks: Operating equipment until failure can increase the risk of accidents and safety hazards.

- Shorter asset lifespan: Running equipment to failure can accelerate wear and tear, reducing its overall lifespan.

What is preventative maintenance?

As mentioned above, preventative maintenance involves regular, scheduled servicing of fleet vehicles to prevent potential issues before they occur. This approach is based on either time or usage metrics, such as mileage, engine hours or calendar time, and generally follows a well-defined schedule or timeline from the original equipment manufacturer (OEM).

Time-based preventative maintenance

Also known as predetermined maintenance, this type of preventative maintenance strategy involves performing maintenance at predetermined intervals. Using OEM timelines provides a reliable, simplified framework for maintenance, however historical data or industry best practices can be leveraged to establish maintenance schedules.

Time-based maintenance helps prevent potential issues, extend the lifespan of assets, and promote consistent upkeep. It provides a structured approach to maintenance, making it easier to plan and manage resources. However, it may lead to unnecessary maintenance on components that are still in good condition.

Usage-based preventative maintenance

Usage-based preventive maintenance is a maintenance strategy that schedules tasks based on actual equipment usage, such as engine hours or mileage. This approach verifies that maintenance schedules are tailored to the actual needs of each vehicle and only when needed, optimizing efficiency and preventing unnecessary downtime.

For example, a fleet might schedule oil changes based on engine hours rather than a fixed time interval, maintaining that oil is replaced when it's actually degraded rather than on a calendar schedule. This approach means that heavily used or harshly operated vehicles receive more frequent servicing, while those with lighter use have longer intervals between maintenance tasks.

Usage metrics offer a customized, efficient approach that adapts to real-world vehicle conditions (in addition to being more cost-effective and efficient than time-based maintenance) as it avoids unnecessary service on components that are still in good condition. However, it requires accurate tracking of equipment usage and therefore a sophisticated monitoring infrastructure. A balanced strategy incorporating both methods can help fleet managers achieve optimal vehicle performance, reduce operating costs and increase fleet longevity.

Pros of preventative maintenance

- Foundation of reliability: Provides a solid foundation by scheduling essential maintenance tasks to help prevent common issues and extend the lifespan of components. This includes routine inspections, servicing and part replacements based on time, mileage or usage.

- Reduced downtime: Verifies that vehicles are regularly inspected and maintained, reducing unexpected breakdowns and unscheduled downtimes.

- Cost management: Regular maintenance can help identify minor issues before they become more expensive, leading to better cost management.

- Improved safety: Regular checks promote identifying and rectifying potential safety concerns, improving overall vehicle and driver safety.

- Extended vehicle lifespan: Routine maintenance can prolong the life of fleet vehicles by verifying that all components are in optimal working condition.

- Maintains compliance: Supports compliance with manufacturer recommendations and industry regulations, staying in line with warranty coverages and minimizing legal risks.

Cons of preventative maintenance

- Over-maintenance: Vehicles can be serviced more frequently than necessary, leading to unnecessary maintenance costs.

- Fixed schedules: Maintenance occurs based on schedule rather than vehicle condition, potentially leading to inefficiencies.

- Resource intensive: Requires significant planning, tracking and execution for adherence to the maintenance schedule.

What is predictive maintenance?

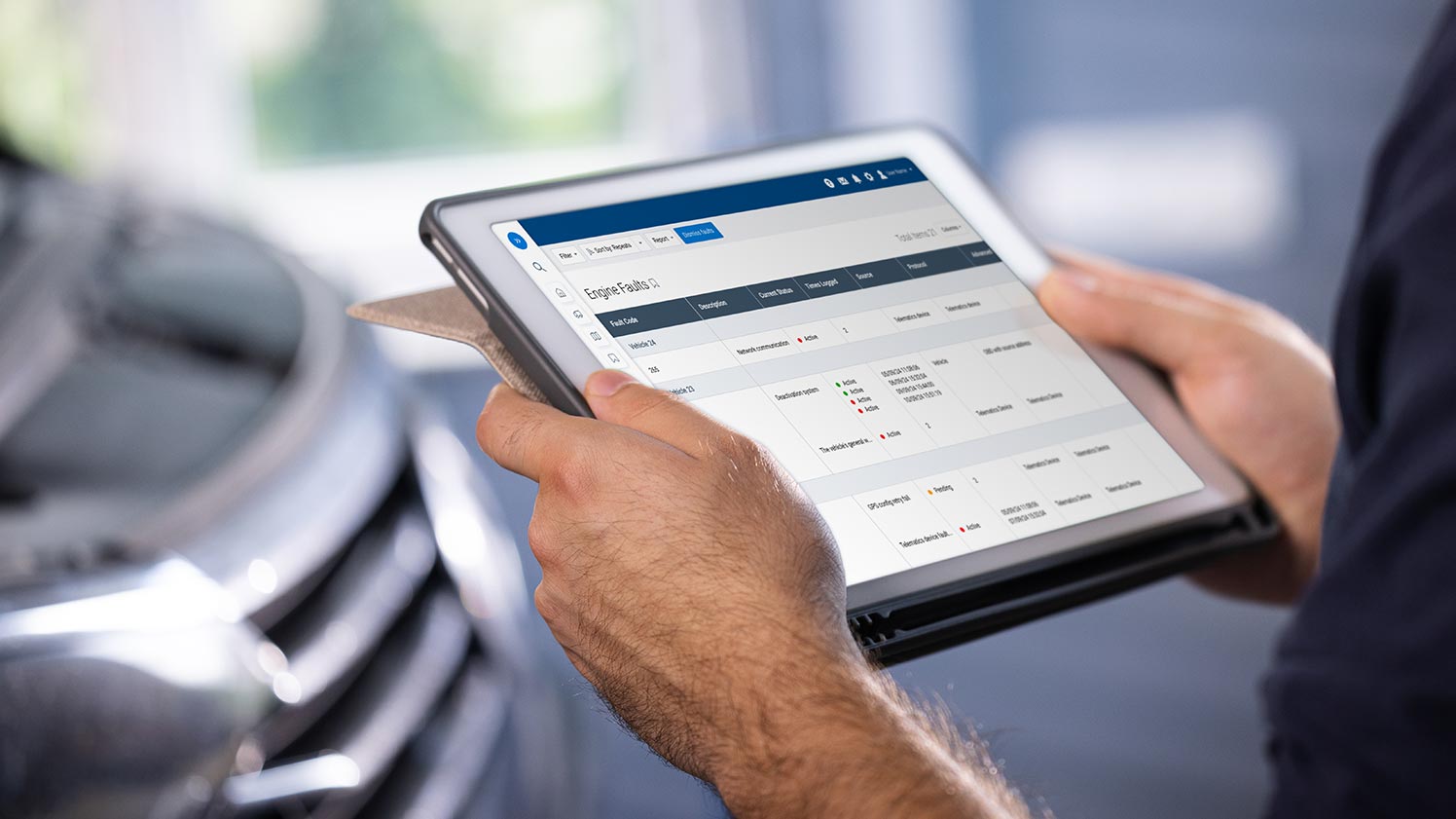

Predictive maintenance represents a targeted and proactive approach to vehicle care, integrating data analytics and near real-time monitoring to foresee and prevent potential issues before they result in costly failures. Unlike traditional maintenance strategies that rely on set schedules or historical data, predictive maintenance continuously assesses a vehicle's current condition through a network of advanced sensors and diagnostic tools. These technologies collect data on various parameters, including engine performance, fluid levels, temperature fluctuations and vibration patterns.

By analyzing this data, predictive maintenance systems can identify subtle changes and trends that indicate wear and tear or imminent component failures. Machine learning algorithms play a crucial role in processing these data streams, enabling the system to learn from historical patterns and refine predictions over time. This allows fleet managers to schedule maintenance tasks precisely when needed, reducing downtime and avoiding unnecessary interventions.

Pros of predictive maintenance

- Reduced maintenance costs: Maintenance is performed only when necessary, based on the vehicle's condition, helping avoid unnecessary maintenance activities and costs.

- Minimized downtime: Predictive insights can help foresee potential failures, including predicting when specific components are likely to fail, allowing maintenance to be scheduled in time to prevent breakdowns.

- Enhanced resource allocation: Optimize maintenance resources by targeting only those vehicles or components needing maintenance.

- Better insights: Continuous monitoring provides detailed insights into vehicle health, improving overall fleet management efficiency.

- Extends asset life: Helps maximize the lifespan of assets by identifying and addressing potential issues before they lead to major failures.

Cons of predictive maintenance

- Initial investment: Requires significant up-front technological investment, including sensors, diagnostic tools and data analytics software.

- Complex implementation: Integrating a predictive approach into existing operations can require specialized skills or training.

- Data dependency: Relies heavily on high-quality data and analytics; inaccurate data can lead to incorrect maintenance predictions.

Selecting the correct maintenance strategy depends on fleet size, vehicle usage and budget. Both methods can improve efficiency and reduce downtime, but each is suited to different operational needs.

Preventative vs. predictive maintenance: What you need to know

Preventative maintenance and predictive maintenance differ primarily in their approach to vehicle care. Preventative maintenance follows a routine schedule based on time or usage metrics, aiming to prevent issues through regular, consistent service. This method simplifies planning while complying with OEM guidelines and maintaining overall reliability through standardized interventions.

Predictive maintenance, however, uses data analytics and near real-time monitoring to assess a vehicle's actual condition. By predicting potential failures before they occur, this approach allows for more precise and timely maintenance actions, optimizing resource use and minimizing downtime.

The following chart highlights the key features and differences between these two maintenance strategies, helping fleet managers choose the best approach for their needs.

| Feature | Preventative Maintenance | Predictive Maintenance |

|---|---|---|

| Approach | Time/Usage-based scheduled maintenance | Condition-based maintenance using data analytics |

| Cost efficiency | Can lead to over-maintenance and unnecessary costs | More cost-efficient by targeting only necessary repairs |

| Technology requirements | Minimal -- Often involves standard diagnostic tools | High -- Requires sensors, near real-time monitoring and analytics from telematics |

| Implementation complexity | Relatively simple to implement and manage | Complex, requires integration with advanced technologies |

| Downtime management | Scheduled maintenance can reduce unscheduled downtime | Helps predict and prevent potential failures, minimizing downtime |

| Resource utilization | Requires predefined resource allocation for scheduled tasks | Optimizes resource allocation based on actual needs |

| Initial investment | Lower initial cost | Higher initial cost due to technology investments |

| Safety improvements | Regular inspections improve safety | Continuous monitoring provides proactive safety measures |

The choice

Choosing between preventative maintenance and predictive maintenance depends mainly on the specific needs and capabilities of the fleet management operation. Preventative maintenance is easier to implement and manage and is often suitable for smaller fleets or those with limited access to advanced technologies. On the other hand, predictive maintenance offers greater efficiency and cost savings in the long run, especially for larger fleets equipped to handle the initial technological investments.

Understanding the pros and cons of each approach, you can develop a tailored maintenance strategy that aligns with your operational goals, budget constraints and technological capabilities. This will ultimately foster a more efficient and cost-effective fleet management system.

Choosing an integrated approach

Choosing between preventative maintenance and predictive maintenance depends mainly on the specific needs and capabilities of the fleet management operation. Preventative maintenance is easier to implement and manage and is often suitable for smaller fleets or those with limited access to advanced technologies. On the other hand, predictive maintenance offers greater efficiency and cost savings in the long run, especially for larger fleets equipped to handle the initial technological investments.

Understanding the pros and cons of each approach, you can develop a tailored maintenance strategy that aligns with your operational goals, budget constraints and technological capabilities. This will ultimately foster a more efficient and cost-effective fleet management system.

It’s ideal to use both preventive maintenance and predictive maintenance as part of a comprehensive maintenance strategy. By combining both strategies, fleets can achieve a more holistic and optimized maintenance approach. Preventive maintenance helps verify that essential tasks are performed regularly, while predictive maintenance adds a layer of proactive and targeted interventions based on near real-time data and analysis. This combined approach helps:

- Minimize downtime: Reduce unplanned downtime by addressing potential issues proactively.

- Optimize maintenance schedules: Fine-tune maintenance schedules based on actual vehicle needs to maximize efficiency and minimize costs.

- Extend asset life: Prolong the life of vehicles and components to maximize return on investment.

- Improve safety: Enhance vehicle safety by helping prevent breakdowns and promoting optimal performance.

Ultimately, integrating both preventive and predictive maintenance strategies creates a more robust and efficient maintenance program, leading to improved fleet performance, reduced costs and enhanced safety for your fleet.

Did you know?

As part of an effort to eliminate data silos between districts, Missouri DOT’s in-house Maintenance Management System (MMS) program was integrated with Geotab through an Application Programming Interface (API). This enabled them to acquire real-time ending engine hours and mileage meter readings, saving time that originally would've been spent manually tracking and reporting this data.

Ultimately, integrating both preventive and predictive maintenance strategies creates a more robust and efficient maintenance program, leading to improved fleet performance, reduced costs and enhanced safety for your fleet.