Module V – How to use telematics to streamline your maintenance program

On the road to fleet health, telematics gets under the hood of your vehicles in near real-time to identify any issues. Are you ready to let data steer your fleet to success?

Managing a fleet's maintenance schedule is complex without the right tools and strategies, especially with numerous vehicles and varied operational demands. Effective fleet management systems and advanced technologies are crucial for streamlining this process. Telematics systems and driver apps offer capabilities to streamline the maintenance process, optimize efficiency and help extend vehicle life cycles.

Telematics has revolutionized fleet maintenance programs, offering a comprehensive approach to vehicle care that enhances efficiency and reduces costs. By leveraging near real-time data, telematics systems provide fleet managers with critical insights into vehicle performance, driver behavior and maintenance needs. Telematics facilitates more informed decision-making by providing diagnostic alerts and detailed reports, keeping vehicles maintained proactively – rather than reactively.

Below, we’ve provided a list of the many ways that telematics can streamline your maintenance cycle and enable you to optimize its vehicle care strategy.

Maintenance reports

Telematics systems are powerful tools for generating insightful reports that unveil trends and areas for improvement. Here’s a list of reports ordered by importance:

High importance

- Engine faults report: Provides a summary of active or historical engine fault codes detected in your vehicles, including severity, frequency and potential impact. This allows you to prioritize repairs and address critical issues promptly.

- Predictive maintenance report: Forecasts upcoming maintenance needs based on vehicle usage, engine data and component wear patterns. This helps you proactively schedule maintenance and minimize downtime.

- Dynamic vehicle maintenance reminder report: Access essential diagnostic faults and key engine data, prioritizing vehicle repairs efficiently and reducing costs by emphasizing predictive engine health.

- Maintenance reminders report: Tracks upcoming scheduled maintenance tasks for all vehicles in your fleet, facilitating timely service and helping prevent missed appointments.

- DVIR defects report: Summarizes defects reported by drivers during their pre- and post-trip inspections, allowing you to identify recurring issues and address potential safety hazards.

High importance (but potentially less frequently accessed)

- Service history report: Maintains a detailed log of all maintenance and repairs performed on each vehicle. This historical data aids in tracking maintenance patterns, identifying recurring issues and planning future service needs.

Medium importance

- Engine hours report: Tracks engine hours for each vehicle, which can be used for usage-based maintenance scheduling and to monitor engine wear and tear.

- Fuel consumption report: Analyzes fuel usage patterns, identifies potential inefficiencies and helps optimize fuel economy.

- Tire pressure report: Provides insights into tire pressure trends, helping you identify slow leaks and verify optimal tire inflation for safety and efficiency.

- Battery voltage report: Tracks battery voltage levels, which can indicate potential battery health issues and prevent unexpected starting problems.

Lower importance (but still valuable):

- Maintenance history report: Provides a comprehensive history of all maintenance activities performed on each vehicle, including dates, services and costs.

- Vehicle health report: Offers an overall summary of the health of each vehicle, including potential issues identified by various sensors and diagnostic data.

- Customizable reports: Allows you to create custom reports based on specific parameters and data points, tailoring the information to your fleet's unique needs.

Did you know?

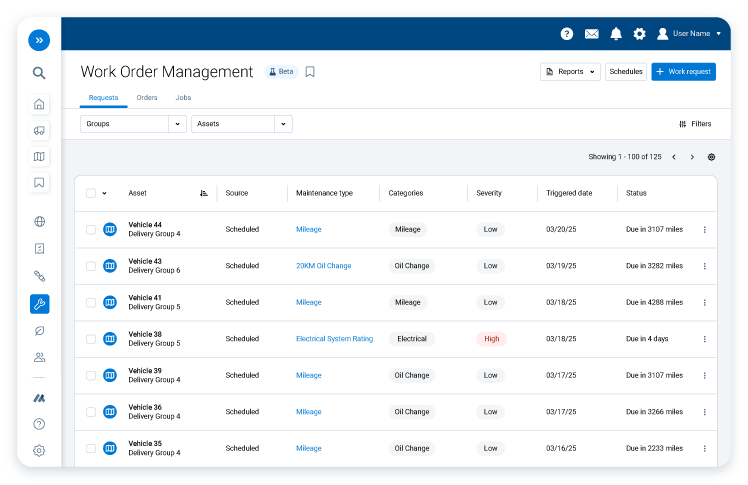

Geotab's Maintenance Center includes Work Order Management, which consolidates scheduling, tracking, and reporting. It also offers Fault Code Enrichment, which enhances fault data analysis by providing insights into fault severity, recommended actions and potential component impact.

Forecasts

An advanced telematics solution provides several valuable forecasts to help your fleet proactively manage vehicle maintenance and minimize downtime.

Predictive maintenance: This feature forecasts the remaining lifespan of key vehicle components, such as brakes, batteries and transmissions, based on near real-time data, historical trends and vehicle usage patterns. This allows fleet managers to anticipate maintenance needs and schedule repairs proactively, helping prevent unexpected breakdowns and optimize component lifespan.

Engine oil life remaining: This forecast predicts the remaining time and mileage before an oil change is due, considering factors like engine hours, mileage and driving conditions. This helps promote timely oil changes, optimizing engine performance and longevity.

Fault code forecasting: By analyzing historical fault code data and vehicle usage patterns, you will be able to see the risk of a breakdown due to fault codes. This allows you to address potential issues proactively and prevent them from escalating into major problems.

Remote diagnostics

Telematics enables remote diagnostics by leveraging the vehicle's onboard diagnostics system (OBD-II) and wireless communication technologies, thereby reducing the need for physical inspections and speeding up troubleshooting. The system automatically detects and identifies diagnostic trouble codes (DTCs) generated by the vehicle's onboard computer, indicating potential issues.

Your staff will be able to access the data remotely through a web portal or mobile app and view near real-time and historical data, analyze fault codes and diagnose potential problems without needing physical access to the vehicle.

Automated maintenance schedules

Automated maintenance schedules help you track vehicle usage and schedule maintenance tasks. This feature will send alerts for upcoming tasks like oil changes, tire rotations and brake inspections. This helps promote timely service, prevents neglect and can extend vehicle life. Schedules can be customized based on mileage, engine hours or time intervals. This proactive approach reduces the risk of unexpected breakdowns and costly repairs.

Did you know?

The Organization for Economic Co-operation and Development (OECD) reported that telematics can help organizations reduce scheduled and unscheduled maintenance and repair incidents by up to 14%.

Tire pressure monitoring

Tire pressure monitoring uses sensors to track pressure and temperature in near real-time. This data is transmitted to a central system, providing fleet managers with nearly instant insights. This telematics capability helps identify if tire pressure is critically low,, reducing the potential for blowouts to occur and improving fuel efficiency. Maintaining optimal tire pressure can help extend tire life and enhance vehicle safety. Alerts notify when pressure or temperature deviates from set ranges, enabling prompt action and minimizing downtime.

Diagnostic alerts

Proactively managing maintenance alerts enhances fleet health, reduces downtime and helps you avoid costly repairs. Here are some critical alerts that fleet managers should monitor closely:

Engine light on: This alert identifies vehicles driving with the “Check Engine” light on and can be used to schedule maintenance or prevent serious issues. The average time to clear a check engine light is 90 days, which means 90 days of performance that could have been optimized.

Battery drain: This alert detects vehicles with a battery voltage below nine volts. Alerts from this rule can help identify general battery problems or remind drivers to turn off their vehicle lights. Assisting drivers in avoiding a dead battery also helps prevent missed service calls, loss of work time and tow truck bills.

Tire pressure monitoring: Alerts for low tire pressure are crucial for maintaining optimal fuel efficiency and vehicle safety. Underinflated tires can increase tire wear and increase the risk of blowouts.

Oil level and quality: Regular monitoring of oil levels and quality results in engines operating smoothly and reduces the risk of engine damage due to insufficient lubrication.

Brake wear: These alerts notify fleet managers when brake pads are worn out or nearing the end of their useful life, promoting timely replacements and helping to prevent brake failures.

Engine hour tracking

Accurately track engine hours to optimize maintenance schedules and help prevent unnecessary wear and tear.

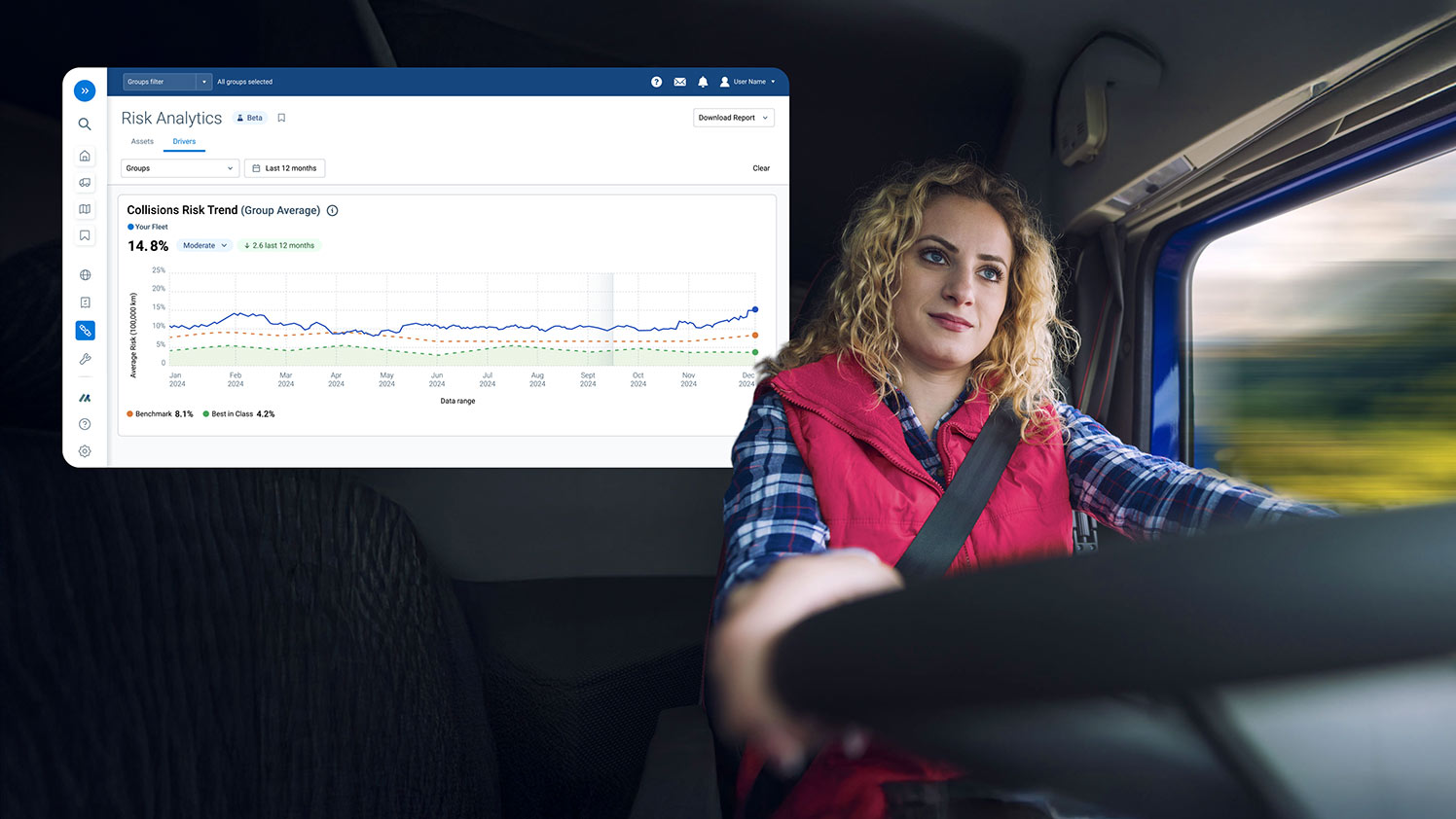

Driver metrics and intervention tools

Implementing tailor-made driving rules can significantly enhance operations, reducing unnecessary wear and tear. By customizing rules such as idle time, harsh braking and route optimization, fleet managers can cut down on repair costs and help prolong the lifespan of the vehicles. For instance, reducing idle time conserves fuel and prevents engine wear. By leveraging telematics and driver-integrated apps, fleet managers can gain real-time insights into driving behaviors and implement corrective actions and training to mitigate these effects.

Did you know?

Geotab’s Measurements tool can help you unearth raw data on maintenance and diagnostics to better understand engine codes. With our platform’s hundreds of diagnostic elements, this feature can enable mechanics to remotely scan vehicles for problems. Additionally, you can create your own rules and be notified ahead of time about engine status details prior to check engine codes being triggered. Through unparalleled customizability and the breadth and quality of our platform’s engine data, you can enhance your fleet’s health in powerful new ways.