Module IV – Analyzing the maintenance journey

On the road to fleet health, the maintenance journey is a crucial roundabout. Are you making smart decisions during each phase of the maintenance cycle?

The vehicle maintenance journey involves many steps and follows a cyclical approach. In this module, we’ll analyze every key step of this vehicle care cycle and show you how to manage downtime, study vehicle risk metrics and take action.

Did you know?

Vehicles travel an average of 37,700 miles between breakdowns or unscheduled repairs, according to a 2024 analysis conducted by American Transportation Research Institute (ATRI).

Step 1: Review downtime metrics

Review your fleet’s macro-level metrics to look for trends and insights that provide you with a holistic view of your fleet’s overall health. It's important to look at both sides of downtime: Pre-downtime and post-downtime.

Pre-downtime

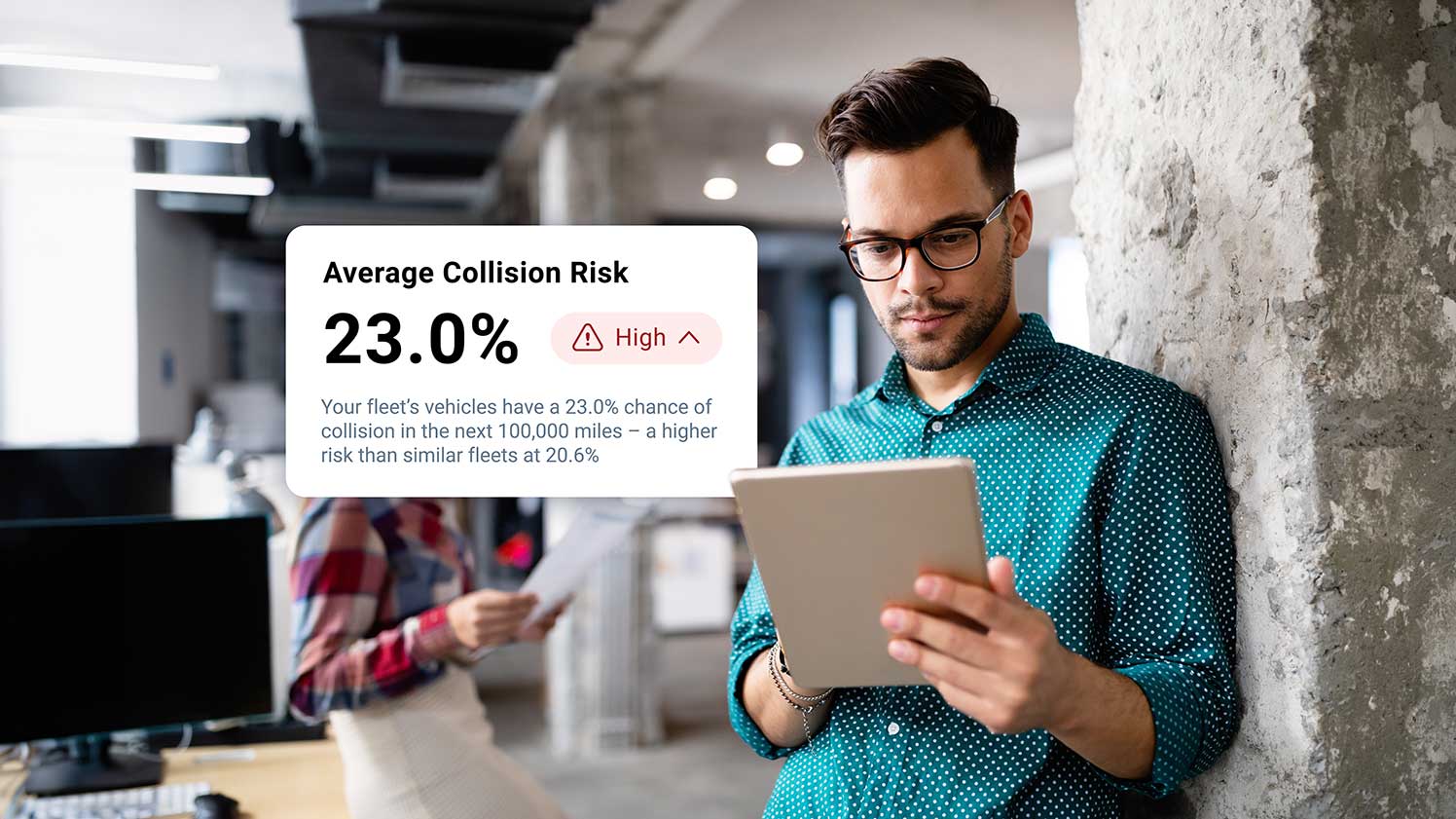

- Risk of breakdown: What is the risk of experiencing a breakdown over my fleet’s next 100,000 miles and what would its potential severity be?

- Risk of collision: What is the likelihood of one of your fleet vehicles experiencing a collision? What could its severity look like?

- Planned downtime: What is my planned downtime for routine maintenance and does it interfere with normal operations?

Post-downtime

- Impact of downtime: What is a vehicle’s level of importance to your operations and how much would it cost you if it was out of commission? How long would it take before the vehicle could be returned to operations? Does your agency have any spare vehicles available to fill the void?

- How many vehicles are currently down: Do you currently have any vehicles that are unavailable due to maintenance needs?

- Total number of breakdowns: How many breakdowns has my fleet experienced in the past and is this an indicator of future problems?

- Downtime by location and breakdown: Are there consistencies in the types of breakdowns that have occurred in your fleet and are there any locations where they typically happen? How long does a typical breakdown take to resolve?

Did you know?

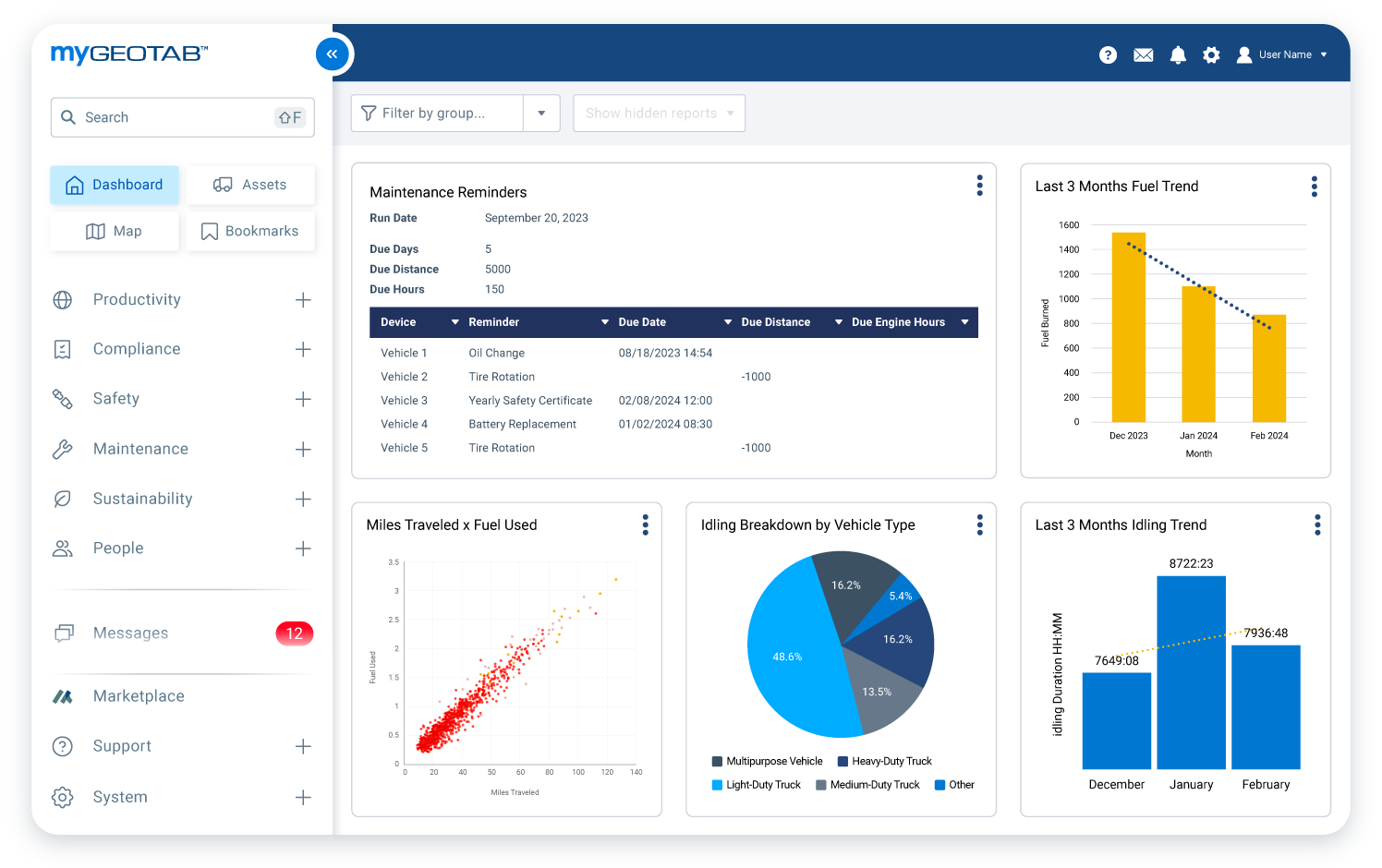

With advanced telematics tools, like Geotab’s remote diagnostics and fleet vehicle management software, you can easily find detailed information on engine diagnostics, scheduled maintenance reminders, and even maintenance cost reports – all in one easy to use app.

Step 2: Review faults and vehicle risk

The next step is to look at your micro metrics to identify which vehicles in your fleet are at risk of a breakdown and why those vehicles are at risk. This is where looking at predictive maintenance metrics becomes essential. There are several ways to identify vehicles that may be at risk of breaking down, though it should be noted that many of these require adopting a solution that allows for detailed maintenance diagnostics, such as an advanced telematics platform. Here’s a list of tools and data to help you not only identify your key vehicles at risk of breakdowns but also pinpoint the specific causes behind those higher risks.

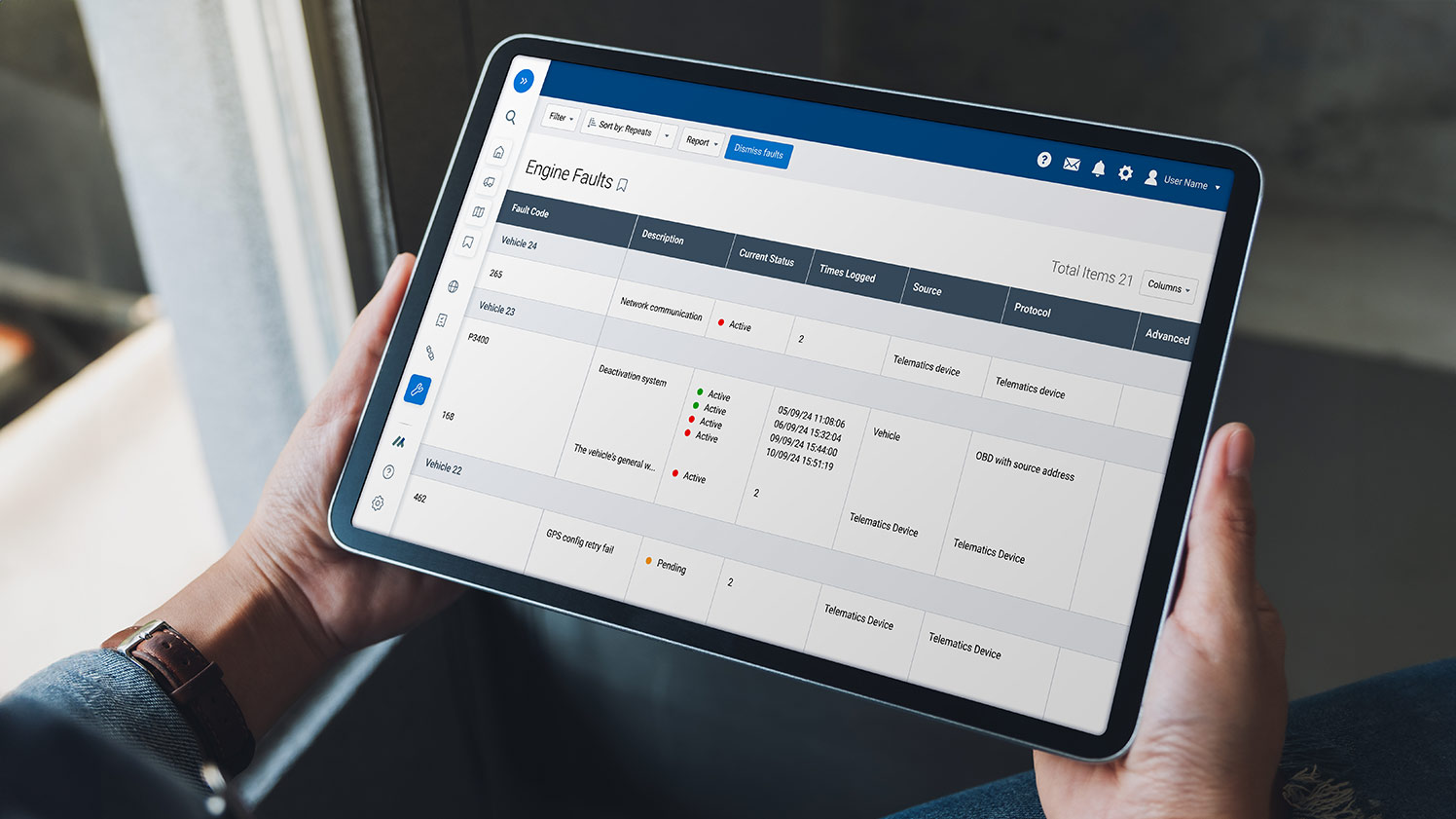

Detailed fault code diagnostics

Fault code monitoring: Look at the combination of fault codes and measurements that lead to a higher chance of breakdown, such as vehicle age, model, remaining useful life and the distance driven with a fault code triggered.

Severity and impact: Beyond simply identifying fault codes, you will want to look for a system that provides fault enrichment data, or detailed information on fault codes’ severity and potential impact on your vehicles’ operation.

Automated prioritization: Prioritizing fault resolution based on severity, with additional information such as vehicle or component effects and recommended next steps.

Troubleshooting information: Look for a solution that can offer the following.

- OEM fault code descriptions

- Time logged information to show the persistence of any issues

- Start and end times of faults based on DTC cycles

Predictive maintenance with component-specific insights

Predictive maintenance: A solution capable of analyzing historical data and vehicle usage patterns to determine when specific components are likely to fail. This enables proactive maintenance scheduling to prevent breakdowns and optimize vehicle lifespans. For example: Geotab's Engine Oil Life Remaining predictions provide estimates for both the time left and distance remaining before an oil change is due (based on a vehicle's typical activity).

Component-level predictions: Looks for a solution that has predictive maintenance capabilities that go beyond general predictions. You’ll want a platform that forecasts the remaining lifespan of specific components, such as brakes, batteries or transmissions.

Data-driven insights: By analyzing historical data, vehicle usage patterns and even external factors like weather conditions, the Maintenance Center can provide insights into why a particular component might be nearing failure.

Did you know?

Geotab’s Electrical System Rating (ESR): provides a comprehensive overview of a vehicle's electrical system health and is able to pinpoint when maintenance should be scheduled for the vehicle and when a battery is likely to fail.

Tire pressure monitoring with advanced diagnostics

Slow leak detection: The "Slow Leak" feature can identify tires that are gradually losing pressure, even if they haven't reached a critically low level. This helps pinpoint tires with potential issues that could lead to breakdowns.

Temperature monitoring: Monitoring tire temperature can reveal issues like excessive heat buildup, which could indicate problems with brakes or wheel bearings.

Did you know?

Adequately inflated tires can extend a tire’s average lifespan by 4,700 miles, according to the NHTSA.

Driver vehicle inspection reports (DVIRs) with detailed feedback

Specific issue identification: Drivers can pinpoint specific issues and provide detailed descriptions, aiding technicians in identifying the root cause of a potential breakdown.

Safety metrics

Safety data can reveal patterns, such as harsh braking or excessive idling, that directly contribute to a component’s wear and tear and can predict the likelihood of collisions. For additional training on fleet safety best practices, we encourage you to explore our Road to Fleet Safety course.

By combining these features, your fleet can move beyond simply predicting breakdowns to understanding their underlying causes. This enables a proactive maintenance approach to vehicle maintenance, helping reduce downtime, extend vehicle lifespans and improve fleet performance.

Did you know?

The State of Utah Division of Fleet Operations significantly cut fleet maintenance costs by leveraging Geotab’s telematics. By employing preventive maintenance, real-time alerts for adverse driving behaviors, automated engine diagnostics and streamlined repair authorization, they reduced maintenance and repair costs by almost $90,000 annually. These savings break down to roughly $82 per vehicle across their 1,091-vehicle fleet.

Step 3: Taking action

The next step in the fleet health journey is to look at your vehicle maintenance workflow and pinpoint any gaps or inefficiencies.

Did you know?

Advanced telematics solutions provide automated reminders for scheduled maintenance tasks, verifying that vehicles receive timely attention and helping prevent potential breakdowns due to neglected maintenance.

Prioritizing vehicle action: How do you prioritize vehicle action? Do you have a system in place to review all vehicles with active fault codes in order to prioritize by severity?

Work requests: What is your current process for creating work requests? Do your work order requests contain all of the salient information needed by a mechanic, with details on fault severity, vehicle effects and recommendations?

Work order assignment: Do you have a system in place that automatically assigns maintenance work orders based on severity?

Vehicle maintenance records: Are you currently recording all of the necessary maintenance information for each vehicle, such as:

- Where is work to be done?

- Who is assigned to do the work?

- When is this work scheduled to be done?

- What parts were purchased and what were their costs?

What is the total cost of the work, including labor?

The vehicle maintenance journey is a multifaceted process that requires careful planning and execution to promote fleet health and efficiency. By understanding each phase of the maintenance cycle, you can make informed decisions that reduce downtime and extend vehicle lifespan. Implementing a proactive maintenance strategy, leveraging tools like fleet management software, and training drivers to conduct daily inspections are essential for optimizing fleet performance. As the maintenance journey is ongoing, continuous assessment and adaptation are key to navigating the challenges of fleet management effectively. By analyzing vehicle risk metrics and taking timely action, you can reduce maintenance costs and improve fleet health.

Did you know?

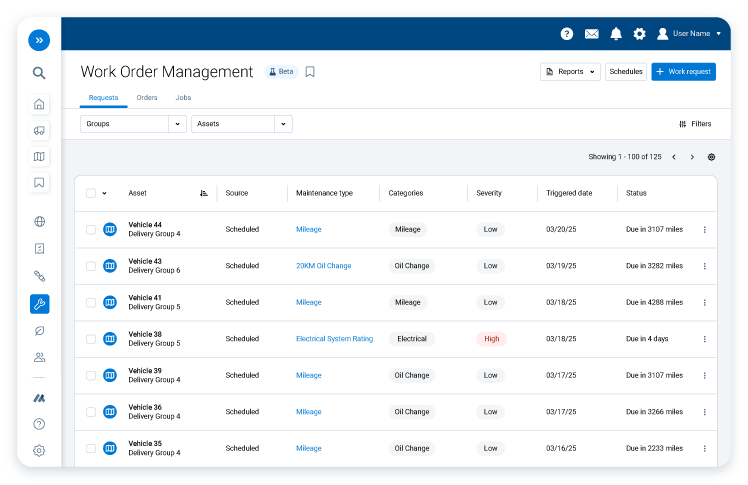

Geotab’s new Work Request page, found in the Work Order Management tab, can be used by a fleet manager or mechanic to view all Work Requests and create a digital work order. With filtering options available by severity of the work request (severity being overdue maintenance, important Geotab insights and more), fleets can easily prioritize which servicing is needed first.