Fleet maintenance solutions

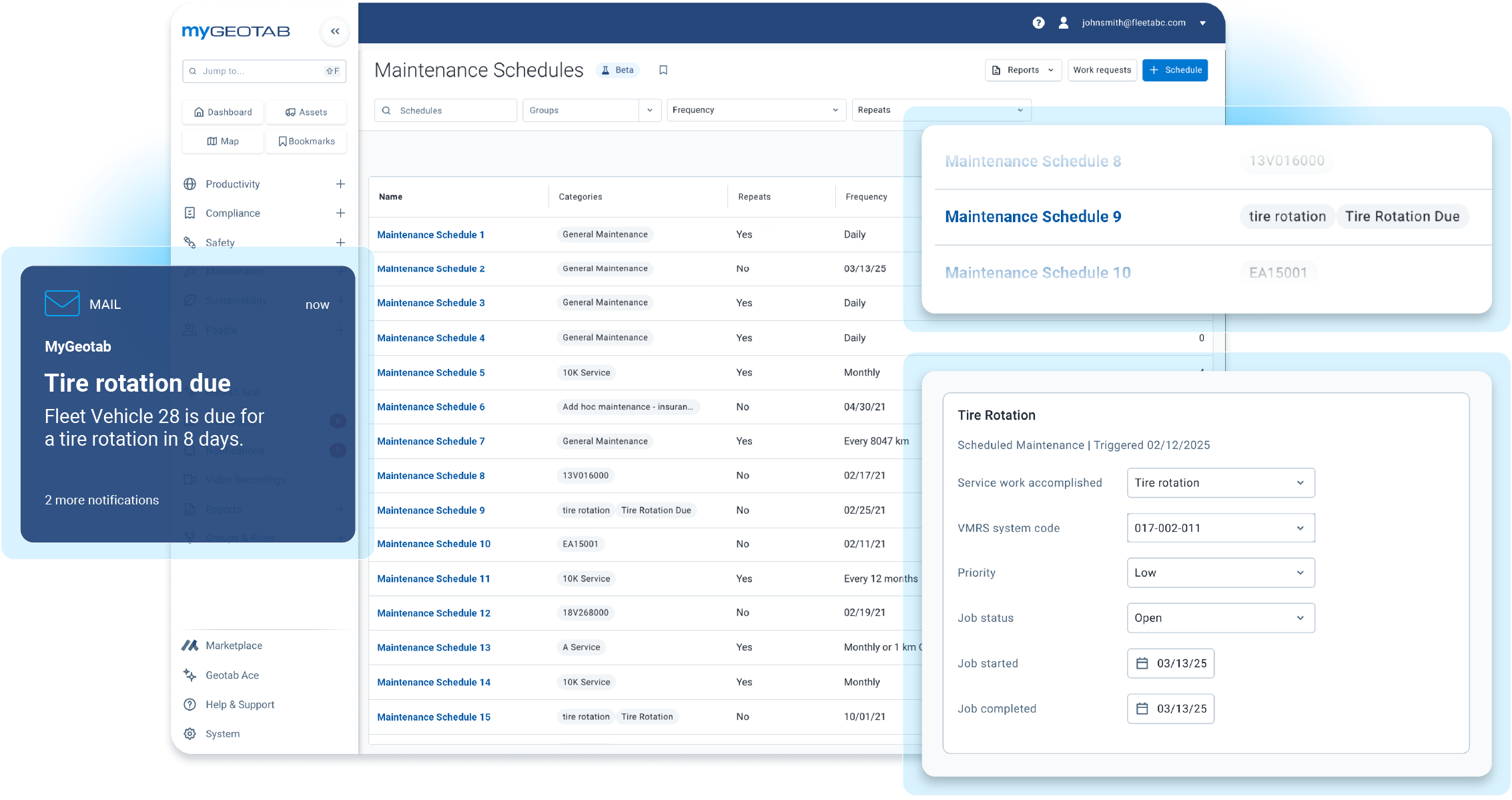

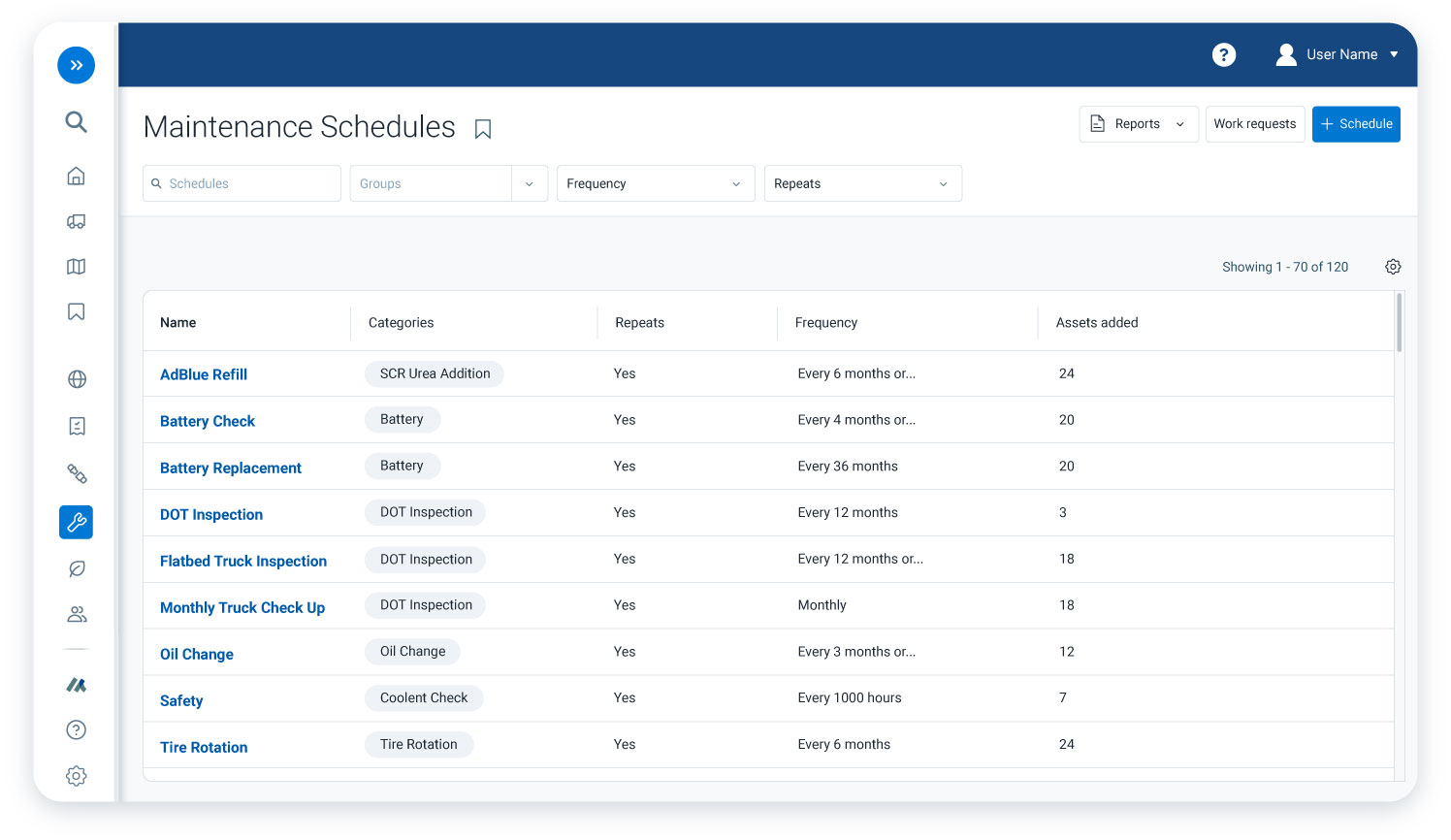

Work order management: Create and manage work orders and set a preventative maintenance schedule within a maintenance management system.

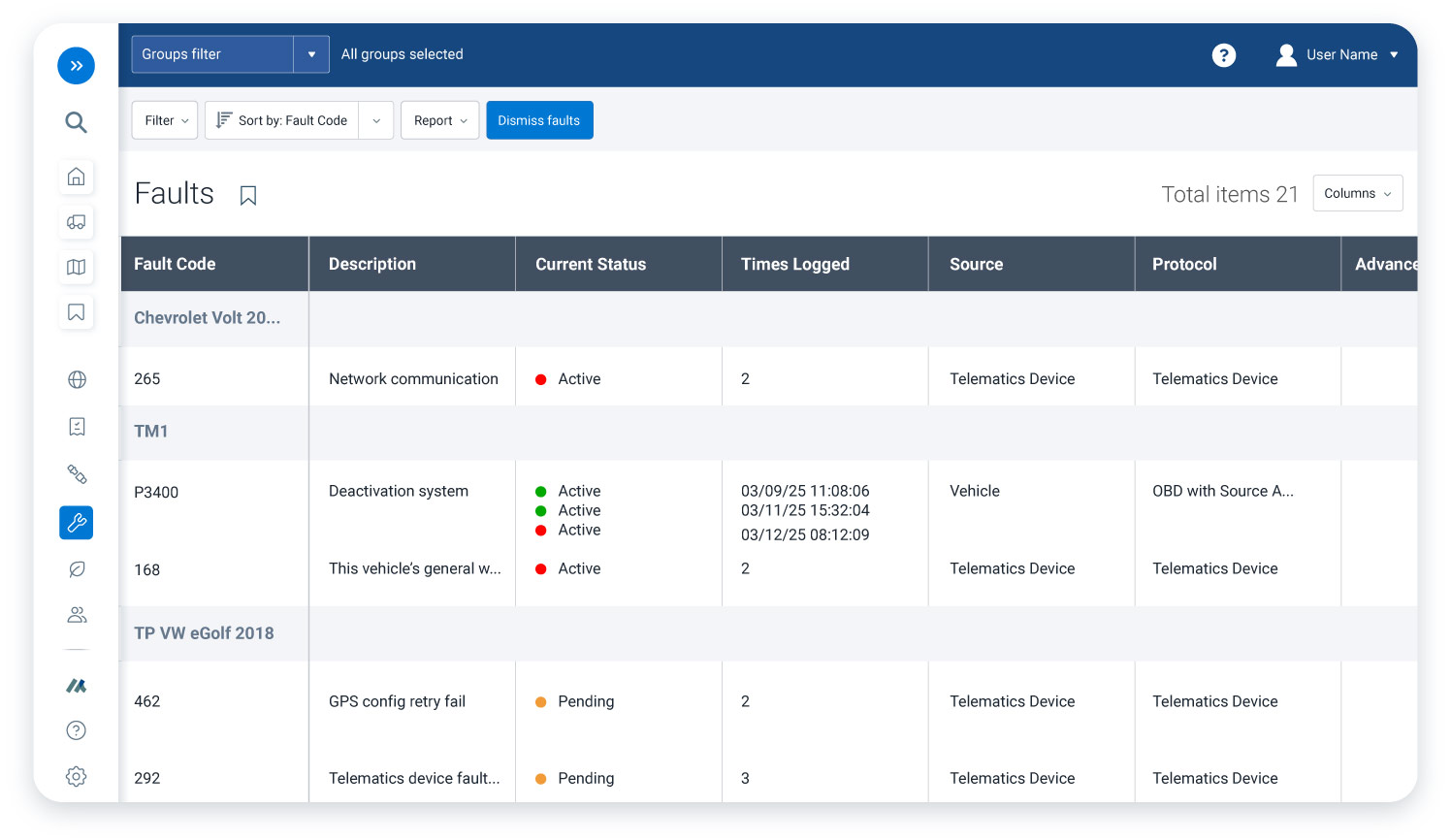

Reduced downtime: Proactively address engine issues and minimize unplanned breakdowns by using remote diagnostics to monitor and prioritize important faults.

Cost savings: Optimise fleet maintenance efforts and reduce unnecessary costs by focusing on high-impact issues.

Streamline work order management

Goodbye to juggling multiple apps and spreadsheets—our streamlined system brings your maintenance schedule and cost tracking all into one place.

By streamlining fleet maintenance workflows and enabling proactive repairs, our solution helps minimise downtime, and extend vehicle lifespan, contributing to significant cost savings.

.jpeg)

Preventative maintenance insights

Proactively attend to engine issues and minimize unplanned events with our comprehensive fleet maintenance insights. By closely monitoring engine fault code information, fleet managers can prioritize high-impact issues and create a preventative maintenance schedule.

Geotab's solution provides accurate data on severity, enabling quick and accurate prioritisation to increase vehicle uptime and reduce costs.

Manage fleet maintenance

Quickly identify issues and prioritize vehicle repairs with active diagnostic faults and critical engine data available through Geotab’s maintenance management system.

Fleet managers can save time and reduce costs by focusing on predictive engine health. This will help fleet managers act accordingly based on the priority of the issue.

This will ultimately lead to increased fleet safety and reduced downtime.

Fleet maintenance tools

- Remote diagnostics

- Inventory management

- Predictive maintenance

- Maintenance scheduling and reminders

- Work order management

- Maintenance cost reports

Software for fleet maintenance and diagnostics from Geotab Marketplace

Maximise uptime and fleet productivity by ensuring your vehicles are operating at their peak. Solutions include predictive maintenance, remote diagnostics, and maintenance management.

Commonly asked questions

What is fleet maintenance?

How does Geotab's fleet maintenance software work?

Using MyGeotab’s engine diagnostics solutions, you can keep your drivers safer, maximize vehicle uptime, and flag potential problem areas so you can plan fleet operations effectively. Geotab’s fleet maintenance software uses remote diagnostics to quickly identify issues and prioritize vehicle repairs with active diagnostic faults and critical engine data, saving you time and money.

How do I set up a fleet maintenance program?

Setting up your maintenance program within a broader fleet management and telematics solution enables you to benefit from remote diagnostics, inventory management, and predictive maintenance capabilities. And you’ll have all your maintenance data together in one place, helping with fleet budgets and forecasts.

What are Geotab's fleet maintenance tools?

• Remote diagnostics to identify small problems before they become large, expensive ones

• Inventory management to streamline the maintenance scheduling process and ensure that everything is on hand when you need it

• Predictive maintenance to reduce vehicle downtime and costly breakdowns on the road by anticipating future maintenance requirements

• Maintenance scheduling and reminders to keep on top of your preventative maintenance program and ensure no inspections, services or faults slip through the cracks

• Work order management to easily log defects from anywhere and track their resolution

• Maintenance cost reports to track work completed and report on costs and trends, helping you target areas where you can improve your bottom line

How can Geotab help improve maintenance for my fleets?

• Increase fleet safety by providing vehicles your drivers can safely depend on

• Control costs by predicting problems and preventing breakdowns from happening

• Keep accurate records, allowing you to maintain service schedules and parts inventory with ease

How does driver behavior affect vehicle maintenance?

How does maintenance software improve fleet safety?

With active diagnostic problems and critical engine data available through Geotab's fleet maintenance software, fleet managers can swiftly identify issues and prioritise vehicle repairs. By focusing on predictive engine health, you may save time and money.