A complete guide to fleet idling: Understand, detect and stop true idling

Idling increases fuel consumption, CO2 emissions, and maintenance costs. Learn how to control it to lower your fuel spend and make your fleet more sustainable.

By Geotab Team

Nov 24, 2025

.jpg)

Key Insights

- High Costs & Environmental Impact: True fleet idling significantly increases operational costs by wasting thousands of liters of fuel annually, leading to unnecessary carbon emissions, accelerated engine wear, and higher maintenance expenses across the fleet.

- Idling Differentiation: Effective fleet management requires distinguishing between true idling (unnecessary waste) and operational idling (necessary engine running for tasks like PTO usage or temperature regulation) to target reduction efforts accurately.

- Key Reduction Strategies: Successful idling mitigation relies on utilising telematic data for precise idle time monitoring and reporting, coupled with comprehensive driver training and the implementation of clear, actionable anti-idling policies.

Despite what you may have heard, turning off your car or truck and then restarting it does not burn more fuel than leaving it running. Some drivers leave their vehicle idling without even thinking about it. For example, an employee waits in their car for a coworker at a local coffee shop, the engine humming in the background. Excessive idling pollutes the air, waste fuel, and causes excess engine wear. Targeting this area can provide significant cost savings for your fleet, and improve its sustainability performance by reducing harmful tailpipe emissions.

True idling versus operational idling

Unlike colder climates, fleets in Southeast Asia don’t face sub-zero engine warm-up requirements. This makes unnecessary idling even less justifiable, as modern diesel engines typically need just one to two minutes to stabilize after startup. Any more than this puts excessive strain on the engine.

Understanding the difference between true idling and operational idling is helpful to managing this area of your fleet operations.

Operational Idling | True Idling |

| Definition: When a stationary vehicle is running to power external equipment, or to warm up a vehicle to legal limits. | Definition: When a vehicle’s engine is running, but the vehicle doesn’t change position. |

| Examples: Idling with a PTO unit to run equipment such as a high-powered vacuum, dump deck, or a towing mechanism on the back of a truck bed. | Examples: Idling while in stop-and-go traffic, drive-through lines, loading docks, or depots. air conditioning, and electronic devices while stationary. |

How does idling harm vehicle engines and systems?

Prolonged car idling degrades engine health and increases operating costs through several core mechanisms. First, low-temperature idling prevents the engine's fuel consumption regulating sensors from reaching optimal operating conditions, resulting in a rich fuel-to-air ratio. This excess fuel strips oil away from the engine’s pistons and cylinders, leading to premature engine aging and accelerated component wear (e.g., piston rings and cylinder liners). Second, inefficient, low-temperature combustion fosters carbon build-up within the engine and contaminates the lubricating motor oil, further increasing abrasive wear. These combined effects directly result in a shorter operational lifespan for the vehicle, necessitating higher maintenance costs, and ultimately causing a significant reduction in the asset value for fleet operators and businesses.

The economic, health and environmental effects of idling

Fuel costs are a major concern in Southeast Asia, where diesel prices have risen sharply in countries like Singapore, Thailand, and the Philippines. Even at conservative estimates, a truck that idles for 1 hour can consume close to 3 liters of fuel. Across a fleet, this adds up quickly:

25 trucks idling for 2 hours daily can waste more than 150 liters of diesel per day or over 45,000 liters per year. At an average Philippine fuel price of ₱60 per liter, fleets can spend nearly ₱3 million a year even without driving a single kilomete.

Diesel exhaust contains many human health-impacting pollutants such as carbon monoxide, volatile organic compounds, nitrogen oxides, and particulate matter. These pollutants are linked to a number of conditions including allergies, heart problems, asthma, lung cancer, and premature death. Since children’s respiratory systems are still developing and they have a faster breathing rate, they are more susceptible to these health conditions than adults.

An idling diesel truck emits 8kg of CO2 per hour, along with pollutants that also contribute to ground level ozone, smog, acid rain, and climate change. All of these emissions can be reduced by preventing unnecessary idling.

Control idling to reduce your organisation’s carbon footprint

Aside from reducing your fuel costs, idling control is an important mechanism for reducing your organisational carbon footprint. The fuel used by the vehicle fleet can represent a significant proportion of an organisation’s scope 1 carbon emissions (those that are directly emitted by owned or leased assets and equipment), and so any improvements made to fleet fuel efficiency can have a notable effect on the overall footprint

While many light-duty fleets are making long-term plans to transition to electric vehicles to completely remove the fleet’s impact on their scope 1 emissions, idling is one of many fleet efficiency areas that can be addressed with immediate gains to reduce the carbon emissions associated with the current fleet and mitigate future carbon tax liabilities as carbon pricing instruments become more stringent across the region

Strategies to reduce idling, save costs and improve your environmental performance

Reducing unnecessary idling is a great first step to reducing costs while making your fleet more sustainable as it can significantly impact fuel economy and CO2 emissions. You can manage your fuel usage by using a fuel management system.

Monitoring idling trends

To fully understand the consequences of idling, you can monitor both the amount of emissions produced and the cost of wasted fuel. It can be valuable to monitor idling trends over time to see how rates are affected by the changing seasons. In Southeast Asia, idling patterns may fluctuate with the seasons — for example, higher during the hot months when drivers keep engines running for air conditioning, or during the rainy season when vehicles wait longer in traffic congestion caused by flooding.

Comparing idling rates between vehicles helps to identify outliers that are in need of management. This can highlight vehicles that would benefit from auxiliary power systems to provide cleaner stationary power than engine idling, or drivers that are in need of additional anti-idling training.

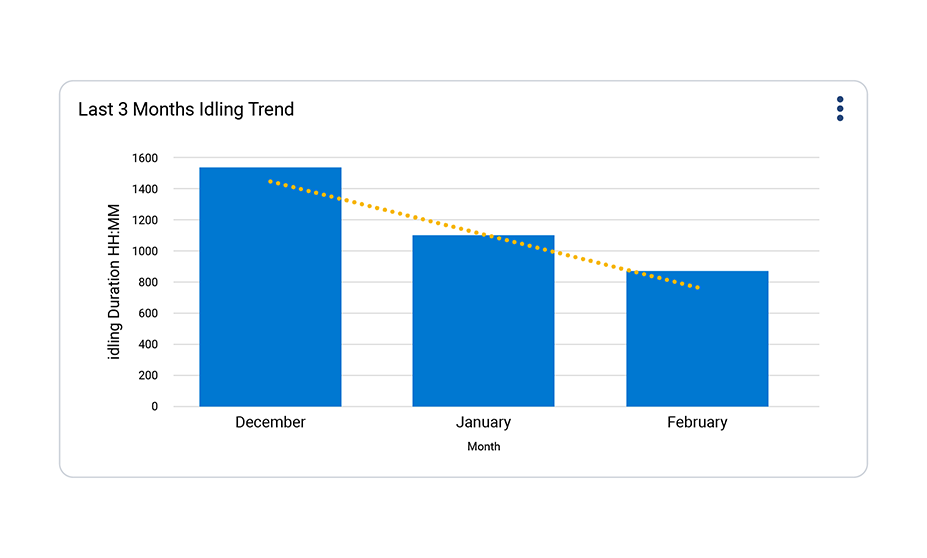

The Geotab Marketplace provides some custom report templates to help you measure your fleet’s true idling rates and exceptions. The Last 3 Months Idling Trend report displays the total idling time for the entire fleet over the last three months, and the Trended Exception Report compares drivers against each other and against daily or weekly trends.

Success story – Tracking idling trends to improve environmental performance

Shaziman Transport, a leading Malaysian logistics provider specializing in petroleum and chemical transport, used Geotab telematics to predict maintenance needs, monitor idling, and coach drivers for safer performance. By reducing unscheduled breakdowns, improving fuel efficiency, and identifying idle hotspots, Shaziman increased vehicle uptime, enhanced safety, and cut emissions across its fleet.

Read the full story here

Driver awareness and training

Idling is usually a state that the driver has chosen to put the vehicle in, so driver awareness and training are key. By implementing a training program, you can ensure that drivers and vehicles are operating at optimal efficiency and provide your drivers with the tools they need to operate their vehicles in a clean and safe manner.

Instantaneous driver feedback can be particularly valuable, since it highlights the behavior in the moment and causes the driver to make immediate adjustments. This can be in the form of in-cab alerts that are triggered when an idling event exceeds a customised threshold.

Another methodology that is gaining traction with fleets is to implement an element of friendly competition between drivers around idling. This can take the form of league tables for monthly idling rates, or prizes and incentives for drivers with the most improved idling rates.

Monitor the impact of your anti-idling strategies on your carbon emissions

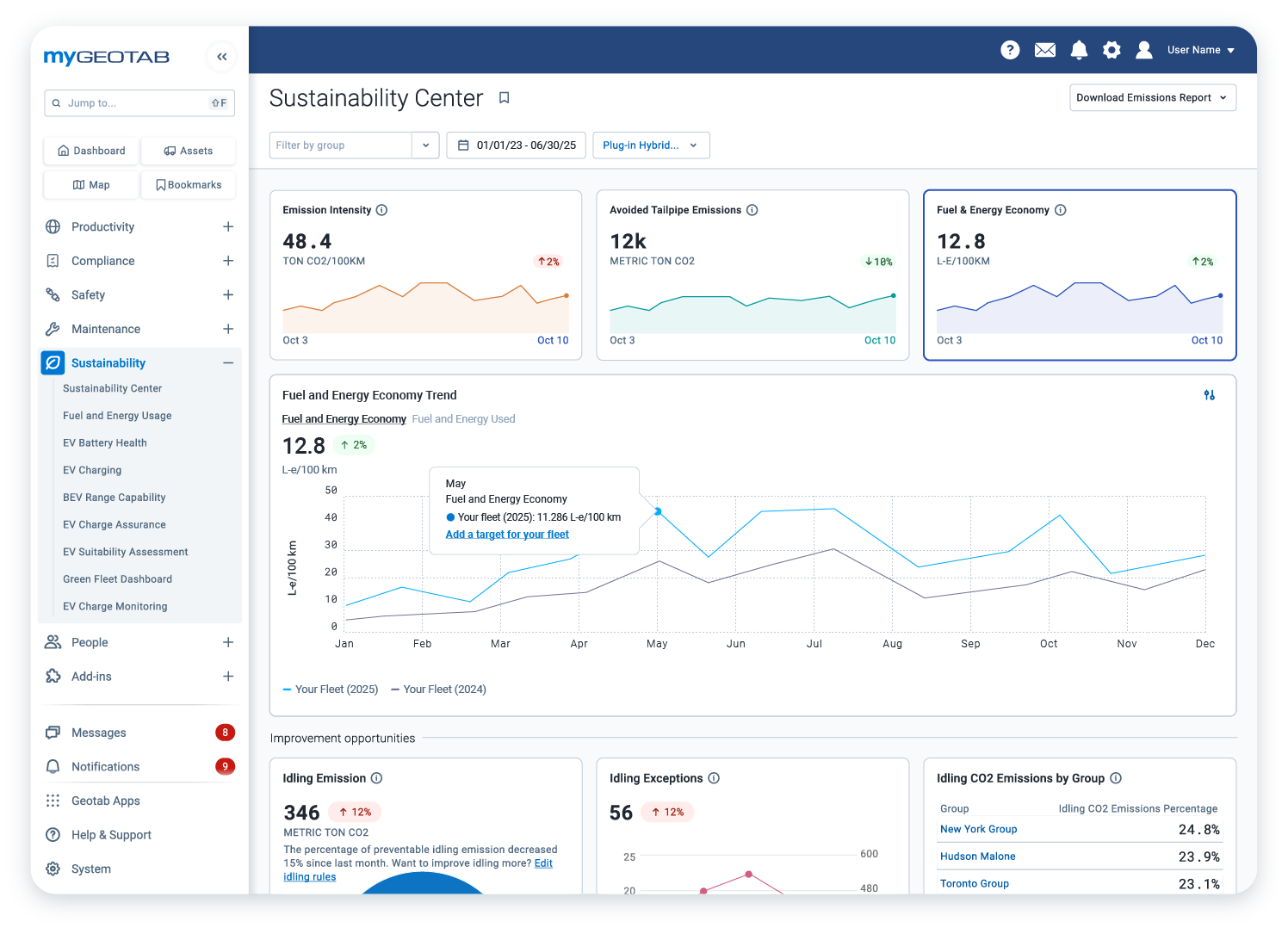

The Sustainability Center enables companies to optimise fleet operating costs and environmental performance, isolating the factors that contribute to excess fuel use so that you can manage the reduction of fleet emissions and improve fuel efficiency. It also provides actionable insights, such as a ranking of fleet groups based on fuel wasted and emissions produced from idling, in order to identify improvement opportunities.

Idling is one of many fleet optimisation practices that can reduce fuel consumption, cut costs and support your sustainable fleet goals. To learn more, check out our blog: Why is fuel management so important for fleet owners

The Geotab Team write about company news.

Related posts

.jpg)

Why Video Telematics is the Future of Fleet Safety in Southeast Asia

February 4, 2026

2 minute read

Unlocking Efficiency in Indonesia’s Logistics Sector: Why Fleet Management Systems Are Key

December 10, 2025

3 minute read

9 strategies to increase fleet fuel efficiency and lower fuel costs

December 8, 2025

4 minute read