Module I – Laying the foundation for fleet maintenance success

On the road to fleet health, maintenance programs pave the way to efficiency. Do you have the right maintenance plans in place?

Establishing a sturdy foundation for your maintenance program is crucial for reaching optimal performance and reliability in your fleet.

By prioritizing fleet maintenance, you can mitigate risks such as breakdowns, costly repairs and safety hazards, keeping your vehicles running smoothly and efficiently. Regular maintenance also enhances vehicle health, helping your vehicles last longer. Identifying issues early can also reduce the need for costly repairs. Additionally, a well-maintained vehicle will generally have a lower total cost of ownership (TCO) and higher resale value.

What does a successful fleet maintenance program look like?

A successful fleet maintenance program is comprehensive and proactive and includes the following five components. Collectively, these components contribute to the overall efficiency, safety and longevity of the fleet, making the maintenance program a cornerstone of effective fleet management.

Maintenance policies

Comprehensive policies including fleet maintenance calendars at the vehicle and fleet level with accurate recordkeeping.

Prompt issue resolution

Implement a system for drivers to report concerns or anomalies that they observe and conduct timely investigations and repairs by qualified technicians.

Efficient inventory management

Maintain a well-organized inventory of necessary parts and supplies to prevent delays.

Continuous improvement

Invest in ongoing training and development for maintenance staff to keep them current with the latest technologies and vehicle systems. Regularly review and optimize maintenance practices.

Advanced diagnostic systems

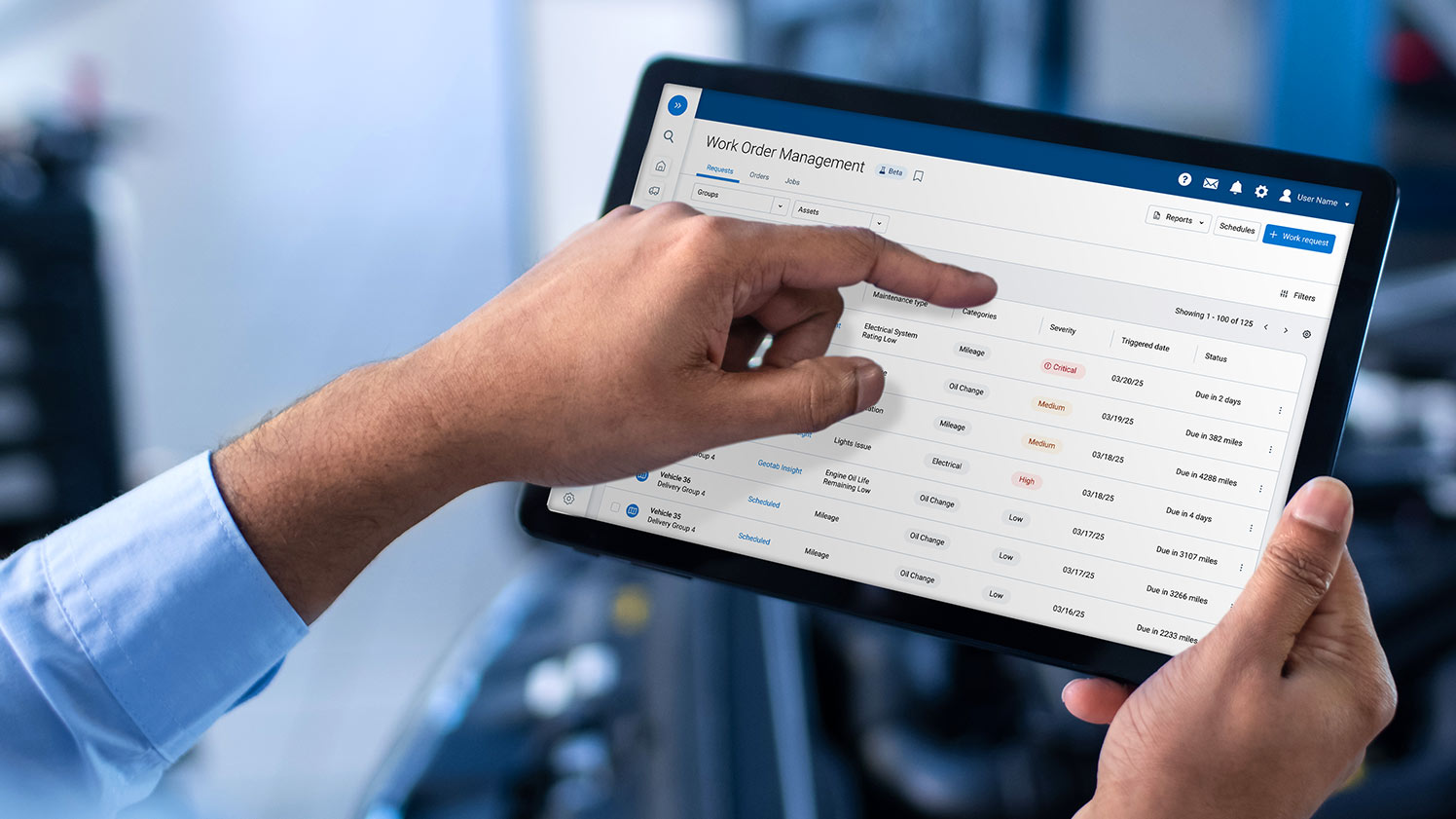

The days of paper-based processes are coming to a close due to their time-consuming nature and the potential for human error to occur. Technology-supported fleet maintenance programs have become sophisticated enough to predict and help prevent potential failures using data-driven insights.

Did you know?

The American Transportation Research Institute (ATRI) reports that maintenance and repair account for about 10% of a fleet's total operating costs. Effective, data-driven maintenance programs can help you crush that benchmark.

Unbeatable benefits with a fleet maintenance program

Developing a proactive maintenance program offers numerous advantages beyond just keeping your fleet in good condition. Here are some key benefits of implementing such a program:

- Improves inspection outcomes: Routine checks help vehicles pass inspections easily, reducing the risk of unexpected faults.

- Reduces operating and repair costs: Early detection of issues helps prevent costly repairs and optimizes vehicle performance, saving money in the long run.

- Increases vehicle longevity: Regular care and timely interventions help extend the lifespans of fleet vehicles, maximizing investment.

- Eliminates unnecessary downtime: Proactive maintenance helps prevent breakdowns, keeping vehicles more consistently available.

- Improves driver safety: Well-maintained vehicles reduce the risk of collisions, better protecting your drivers.

- Aids in ESG goals: Maintenance programs support environmental, social and governance (ESG) objectives by verifying that vehicles operate efficiently and keep emissions lower.

Addressing common fleet maintenance program challenges

Implementing an effective fleet maintenance program requires tackling a variety of challenges head-on. From coordinating maintenance schedules to managing costs and maintaining regulatory compliance, overcoming these obstacles is crucial to run a smoothly operating, long-lasting fleet. Listed below are the most common fleet maintenance challenges that you are likely to encounter.

Scheduling and planning

Coordinating maintenance for numerous vehicles can be complex, requiring a robust scheduling system.

Managing costs

Keeping maintenance expenses within budget while upholding quality service can be challenging.

Tracking maintenance history

Accurate records of each vehicle’s maintenance history are critical for informed decision-making.

Maintaining compliance

Verifying that all vehicles comply with regulations and industry standards requires diligent oversight.

Managing parts inventory

Efficiently organizing and tracking the parts inventory is vital to minimize delays in maintenance.

Changing driver behavior

Unsafe driving habits, like harsh braking or speeding, can cause premature wear and increase maintenance needs highlighting the need for a robust driver training program. Learn more here >

Did you know?

The average fleet maintenance cost per mile ranges from $0.15 to $0.18, according to the National Private Truck Council. How does your fleet measure up against this?

Laying the foundation: It all starts with a maintenance policy

The first step in laying the foundation for your fleet maintenance program is developing a strong vehicle maintenance policy. This document should include clear instructions, creating consistency between all policies and procedures and outline the following:

- Maintenance checklists – What needs to be covered as part of the regular maintenance checkup.

- Service history – Records of past maintenance, including dates and service intervals, services performed and who the mechanic was.

- Service dates – Comprehensive maintenance schedules with clearly defined vehicle service dates for each item in the maintenance checklist.

- Responsibility – Designated personnel responsible for various maintenance aspects.

- Emergency procedures – Guidelines for handling unexpected breakdowns or incidents.

By establishing a clear vehicle maintenance policy related to fleet vehicles, you can proactively manage vehicle health, minimize downtime and optimize fleet productivity. This structured approach supports uptime, improves fleet productivity and manages vehicle wear, contributing to a safer and more efficient fleet operation. In addition, it is vital to prove ‘duty of care’ for your vehicles.

Did you know?

Duty of Care is the legal obligation of an organization or a person to avoid acts or omissions that are likely to cause harm to others. For fleet-based agencies, this includes providing your drivers with suitable and safe vehicles.

The Federal Motor Carrier Safety Administration (FMCSA) mandates that organizations with fleets must systematically maintain and repair their vehicles. A well-communicated maintenance policy and program demonstrates a commitment to Duty of Care. Your agency should be able to show a consistent history of compliance and enforcement.