Fleet maintenance management software

Take a proactive approach to fleet maintenance. Maximise uptime and reduce costs with our fleet maintenance management software.

Optimise fleet maintenance

Using fleet vehicles that are in top condition is critical to the success of your fleet. Quickly identify issues and prioritise vehicle repairs with active diagnostic faults and critical engine data available through Geotab’s fleet maintenance solution. Streamline your fleet maintenance programme, and ensure that preventative maintenance never slips through the cracks.

Proactive fleet maintenance eliminates vehicle downtime

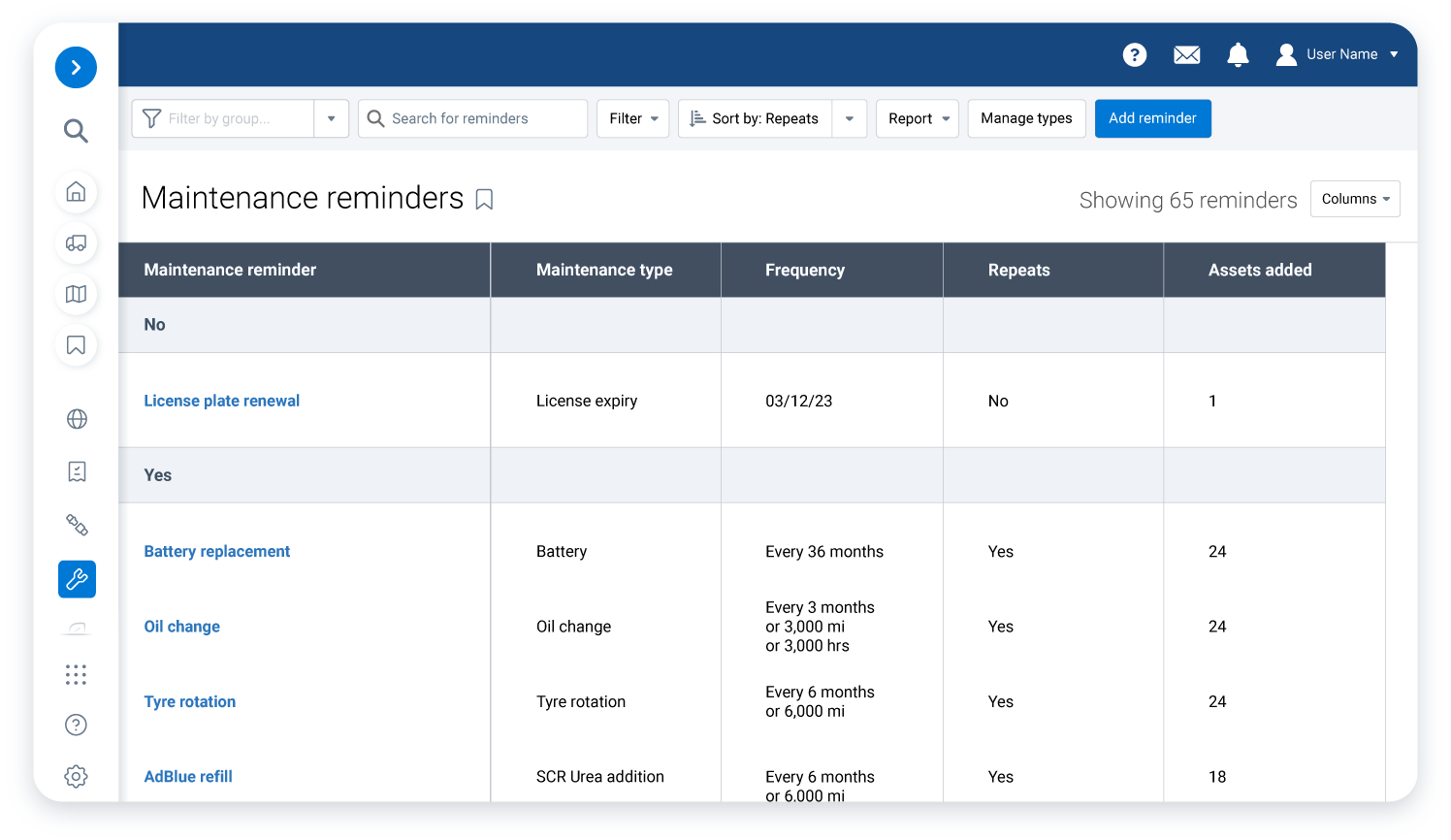

The more time your fleet vehicles spend in the garage rather than on the road, the more it impacts your fleet’s profitability. Eliminate vehicle downtime with Geotab’s end-to-end maintenance management software. Use MyGeotab to forecast and schedule your fleet’s regular service tasks and inspections, and keep accurate records of vehicle issues, fleet maintenance schedules, and parts inventories to ensure the maintenance scheduling process always runs smoothly.

Detect engine issues early with predictive fleet maintenance tools

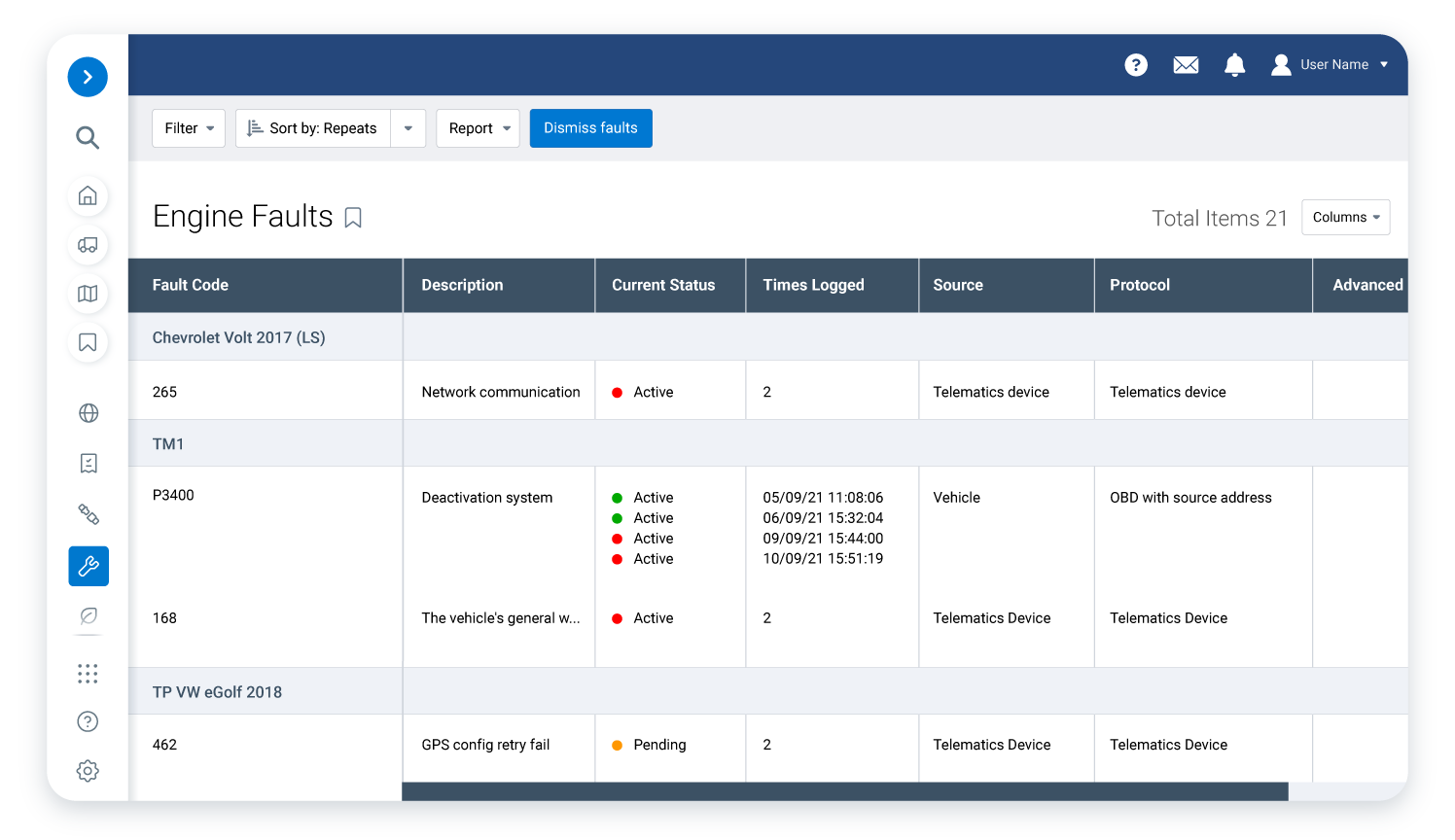

Save time and reduce costs by focusing on predictive engine health. By closely monitoring your engine fault code information, you can proactively attend to engine issues before they turn into costly repairs or vehicle downtime. These vehicle codes quickly identify and locate the engine issue, helping you save on vehicle inspection time and costs. With our fleet maintenance management software you can add an extra level of awareness by having fault codes emailed to you from MyGeotab as they occur.

Fleet maintenance solutions

- Remote diagnostics

- Inventory management

- Predictive maintenance

- Maintenance scheduling and reminders

- Work order management

- Maintenance cost reports

Fleet maintenance and diagnostic solutions from Geotab Marketplace

Maximise uptime by ensuring your vehicles are operating to their peak potential. Fleet maintenance solutions include predictive maintenance, remote diagnostics, collision reconstruction and maintenance management.

Commonly asked fleet maintenance questions

What is fleet maintenance?

Fleet maintenance is often broken down into two parts: preventative maintenance and predictive maintenance. Preventative fleet maintenance is regularly scheduled maintenance on a vehicle to reduce breakdowns. Predictive fleet maintenance is performed when remote diagnostic data suggests that timely intervention will avoid breakdowns and expensive repairs. By using both of these methods, fleet managers can maximise vehicle uptime, control maintenance costs, increase fleet safety and fleet productivity.

How does Geotab's fleet maintenance software work?

Geotab’s fleet maintenance software helps to increase the lifespan of your fleet by catching small problems before they become large, expensive ones. With MyGeotab, you can forecast and schedule your fleet’s regular service tasks and inspections, and keep accurate records of vehicle issues, fleet maintenance schedules, and parts inventories to ensure the maintenance scheduling process always runs smoothly.

Using MyGeotab’s engine diagnostics solutions, you can keep your drivers safer, maximise vehicle uptime, and flag potential problem areas so you can plan fleet operations effectively. Geotab’s fleet maintenance software uses remote diagnostics to quickly identify issues and prioritise vehicle repairs with active diagnostic faults and critical engine data, saving you time and money.

How do I set up a fleet maintenance programme?

A fleet maintenance plan is paramount to operational and business success. Fleet maintenance minimises downtime and maximises revenue. If you don’t have a maintenance programme in place, you are putting your vehicles and drivers at a much higher risk of accidents, breakdowns and costly downtime. Setting up a fleet maintenance plan also helps keep your vehicles running in top shape, which can have a direct effect on the efficiency and fuel economy of your vehicles.

Setting up your maintenance programme within a broader fleet management and telematics solution enables you to benefit from remote diagnostics, inventory management, and predictive maintenance capabilities. And you’ll have all your maintenance data together in one place, helping with fleet budgets and forecasts.

What are Geotab's fleet maintenance tools?

Geotab makes managing fleet maintenance and diagnostics easy. We offer the following tools to help you manage all of your fleet maintenance and diagnostic needs:

• Remote diagnostics to identify small problems before they become large, expensive ones

• Inventory management to streamline the maintenance scheduling process and ensure that everything is on hand when you need it

• Predictive maintenance to reduce vehicle downtime and costly breakdowns on the road by anticipating future maintenance requirements

• Fleet maintenance scheduling and reminders to keep on top of your preventative maintenance programme and ensure no inspections, services or faults slip through the cracks

• Work order management to easily log defects from anywhere and track their resolution

• Maintenance cost reports to track work completed and report on costs and trends, helping you target areas where you can improve your bottom line

How can Geotab help improve maintenance for my fleets?

• Increase fleet safety by providing vehicles your drivers can safely depend on

• Control costs by predicting problems and preventing breakdowns from happening

• Keep accurate records, allowing you to maintain service schedules and parts inventory with ease

How does driver behaviour affect vehicle maintenance?

Driver behaviour plays an important role in reducing the need for fleet maintenance. For example, a driver who is constantly braking sharply, travelling at high speeds or performing other unsafe driving habits can cause accelerated wear to the vehicle.

What other fleet management solutions does Geotab offer?

Geotab offers many other fleet management solutions, particularly to help with productivity, fleet optimisation, safety, sustainability, compliance and future-proofing.

To learn more about Geotab solutions, visit our Fleet Management Software Solutions page.

How does maintenance software improve fleet safety?

Driver conduct has a significant impact on the need for vehicle maintenance. A motorist who repeatedly participates in hard braking, speeding or other risky driving behaviour, for example, might cause a vehicle's wear and tear to be accelerated.

With active diagnostic problems and critical engine data available through Geotab's fleet maintenance management software, fleet managers can swiftly identify issues and prioritise vehicle repairs. By focusing on predictive engine health, you may save time and money.

How can fleet maintenance software save unwanted costs?

Fleet maintenance software can save on unwanted maintenance costs by prioritising the vehicles that need attention the most. Geotab's fleet management software can be used to pull engine problem codes and analyse a variety of other data points to determine which vehicles require your mechanic's assistance first. Prioritise vehicles and shift from reactive to proactive maintenance, increasing both the fleet's and support crew's productivity.