What is ABS and what does it do?

ABS (Anti-lock Braking System) improves vehicle safety by preventing wheel lock-up, enhancing control during braking, and maintaining stability.

January 12, 2026

•4 minute read

Definition

- ABS is an acronym for anti-lock braking system, a vehicle safety feature that prevents wheels from locking up during braking.

- ABS allows the driver to maintain steering control by rapidly modulating brake pressure, ensuring that the wheels continue to rotate instead of skidding.

- For fleet operations, ABS technology is key to preventing collisions, minimizing vehicle damage and reducing maintenance costs.

- Regular maintenance of ABS components like sensors and brake pads ensure reliable operation performance and safety.

Hard braking does not have to mean losing control. Anti-lock braking systems (ABS) are a critical piece of driving technology that prevents wheel lock-up. This allows drivers to maintain steering stability when it counts. By using sensors to monitor wheel speed and a controller to adjust brake pressure accordingly, ABS keeps your vehicle safe and in control.

For fleet managers, ABS is essential to protecting drivers, reducing collision rates and maintaining operational efficiency. Fleet vehicles often operate under challenging conditions, making reliable brakes critical. This article covers exactly what ABS is, how it works, the different types available and why it is so important.

What is ABS?

What exactly are anti-lock brakes, and what does ABS stand for? ABS is an acronym for anti-lock braking system, a vehicle safety feature that prevents wheels from locking up during braking. It’s an Advanced Driver Assistance System (ADAS) that enables the driver to maintain steering control by rapidly modulating brake pressure, so the wheels can continue to rotate instead of skidding.

Unlike regular brakes, which cause the wheels to lock and skid when applied too forcefully, anti-lock brakes automatically pulse brake pressure to prevent skidding while maintaining effective braking. Understanding this difference is especially helpful for fleets looking to strengthen their defensive driving techniques.

The first application of ABS was in the 1920s for aircraft landing systems before it was adopted for cars and motorcycles in the 1950s and 1960s. It became a standard feature in most modern vehicles after Mercedes-Benz and Bosch adopted it in the late 1970s and early 1980s.

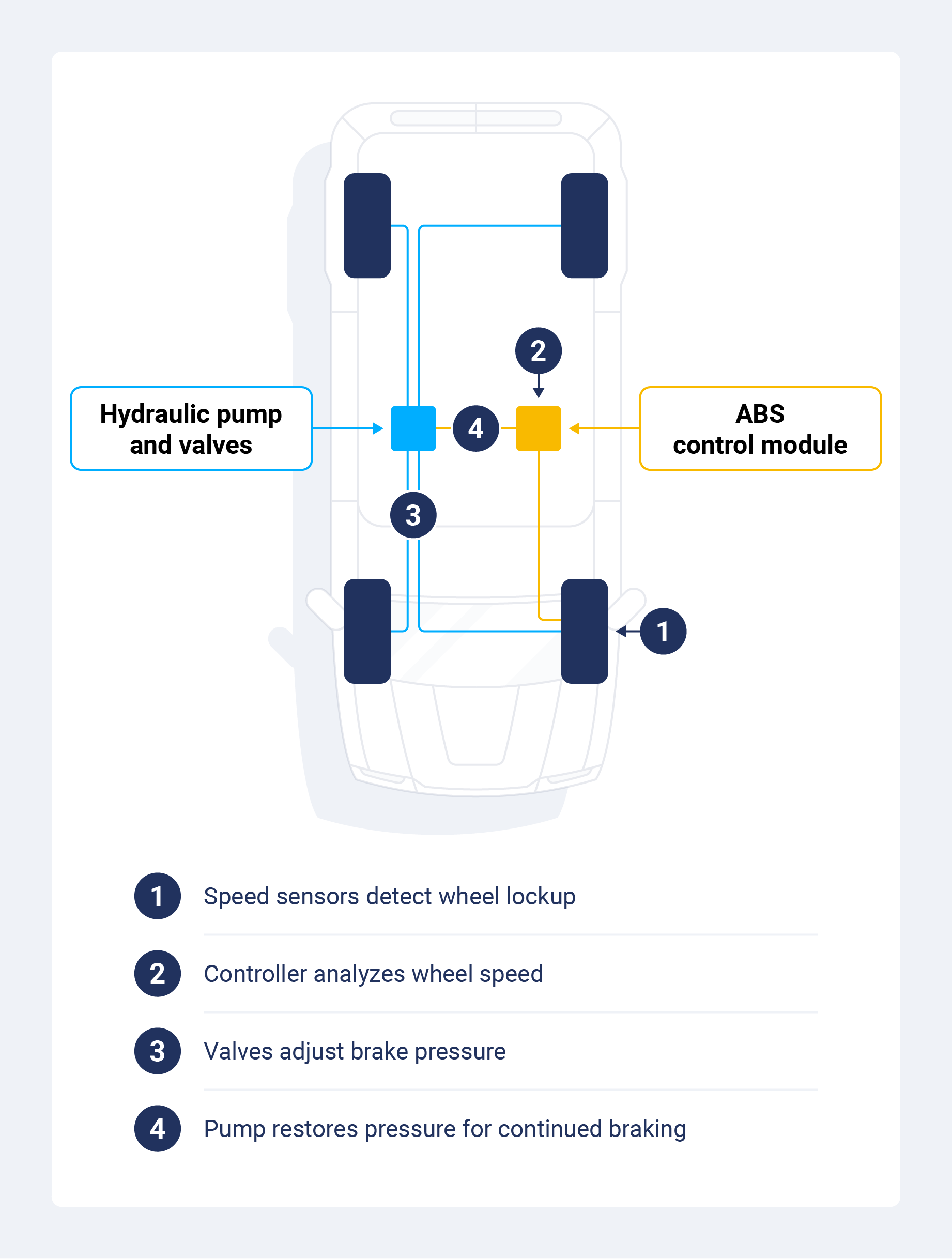

How does ABS work?

ABS activates when the system detects that one or more wheels are about to lock up during braking. This is typically triggered by poor driving habits like rapid deceleration or hard braking situations.

You will be able to tell that your anti-lock brakes have been activated by the pulsating sensation in the brake pedal, often accompanied by a clicking or grinding sound. This is the system rapidly applying and releasing brake pressure to reduce the likelihood of wheel lock-up.

ABS uses four main components working in tandem to accomplish this:

- Speed sensors: The ABS controller continuously monitors the speed of each wheel via speed sensors. When a sensor detects that a wheel is decelerating abruptly, signaling imminent lock-up, the controller takes over.

- ABS controller: The system monitors wheel speed sensor data and modulates brake pressure by controlling hydraulic valves.

- Valves: In the brake line, the ABS valves regulate brake pressure to help reduce lock-up. They can open, close or partially close depending on the situation.

- Pumps: When the valves release pressure to prevent lockup, the pump restores it by pushing brake fluid back into the system. This allows braking force to be quickly reapplied, maintaining performance and vehicle control during emergencies.

Benefits of anti-lock braking systems

ABS provides significant safety and operational benefits for fleet vehicles, including:

- Enhanced vehicle control: ABS prevents wheel lock-up during harsh braking, allowing drivers to maintain steering control in emergencies.

- Reduced stopping distance: ABS can help reduce the stopping distance required, especially under slippery road conditions.

- Adaptability: ABS adapts to improve braking performance on wet, icy, or uneven road conditions.

- Decreased tire wear: By preventing wheel lock-up, ABS can reduce flat spots and excessive wear on tires.

- Preventing costly collisions: ABS minimizes skidding and wheel lock-up during emergency braking, reducing the likelihood of collisions.

- Improved driver safety: ABS helps drivers stop safely, protecting both personnel and cargo, while improving overall fleet management KPIs like reliability and efficiency.

Common ABS warning light causes and fixes

An ABS light means the system has detected a malfunction. Common causes include:

- Faulty wheel speed sensors

- Low brake fluid levels

- Blown fuses

- Worn brake pads

To address the ABS warning light, you will want to:

- Check your brake fluid levels and top off if needed.

- Inspect wheel speed sensors for any buildup or damage.

- If the issue persists, have a qualified technician run diagnostic tests to identify specific fault codes.

Never ignore an illuminated ABS light. It means you will have reduced braking performance in an emergency situation, and could pose a risk to your drivers.

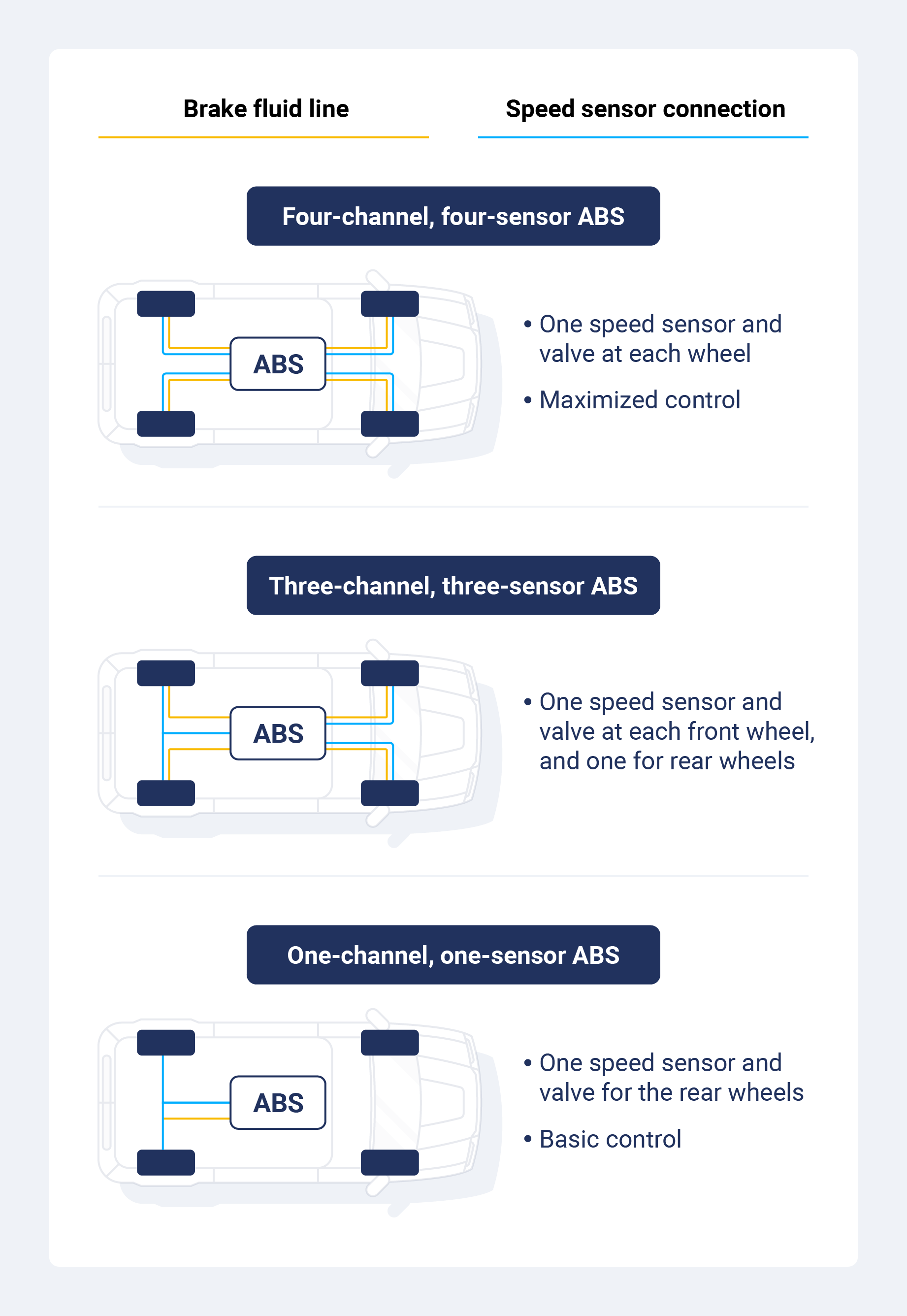

What are the different types of ABS?

All vehicles come standard with ABS nowadays. However, depending on your vehicle, the type of ABS it is equipped with may differ.

- Four-channel, four-sensor ABS: This system, found in most cars and SUVs, has each wheel equipped with its own speed sensor and separate valve. This configuration offers the best control and is standard for most passenger and light-duty fleet vehicles.

- Three-channel, three-sensor ABS: Each front wheel has its own speed sensor and valve and the rear wheels have one sensor and valve. This system balances cost and performance for medium-duty vehicles like pickup trucks and other medium-duty vehicles.

- One-channel, one-sensor ABS: Found in older vehicles and some trucks, this system has one sensor and valve for both rear wheels. Though less sophisticated, it still offers basic anti-lock performance.

Modern commercial vehicles might also include advanced systems like Electronic Braking Performance Management Systems (EBPMS). These work alongside ABS to optimize braking performance and overall safety.

How to maintain your anti-lock braking systems

Keeping your fleet's ABS in optimal condition is essential for safety and cost control. Here are some best practices to keep everything well-maintained.

Regular inspections

Schedule routine inspections of ABS components. Make sure to check:

- Wheel speed sensors: These are especially vulnerable to damage from road debris and corrosion.

- Wiring harnesses: Technicians should inspect, clean and check electrical connections when reviewing harnesses.

- Brake fluid levels: Check and regularly replace per manufacturer instructions since contaminated or low brake fluid can compromise ABS performance.

Establishing a regular maintenance inspection tied to mileage or time intervals means you will have consistent ABS performance across your entire fleet.

Brake pad and rotor maintenance

How effective your ABS system is depends on properly functioning brake pads and rotors. Worn brake pads reduce brake force and can trigger ABS warning lights because of irregular brake patterns. Worn or warped rotors can also compromise your system's ability to perform well.

Make sure to replace brake pads before they reach minimum thickness specifications, and resurface or replace rotors as needed to maintain smooth, even braking surfaces. Monitor acceleration, braking and cornering patterns to find vehicles that might need servicing.

Monitoring ABS warning lights

Never ignore ABS warning lights. The light will only come on when the system detects a fault, indicating your anti-lock brake system might not be functioning correctly. Address warning lights immediately with a qualified technician.

After you have finished repairs, the ABS should turn off automatically after the system runs a self-check. If the light remains on, the technician can show you how to reset the ABS light with a verified diagnostic scanner tool. Some systems might need a test drive to complete the reset process.

Keep your fleet in control with anti-lock braking systems

From a fleet safety perspective, anti-lock braking systems are crucial for preventing costly collisions. ABS technology directly translates to improved driver safety and minimized potential damage to vehicles and cargo. Regular maintenance and monitoring of braking patterns with telematics only add to the many benefits of anti-lock braking systems.

Understanding how your ABS system works and maintaining it keeps your fleet safe and operational. Learn more about how you can optimize your fleet's braking performance and safety protocols by exploring Geotab's fleet maintenance solutions.

Frequently Asked Questions

Most vehicles made after 2012 come with standard ABS. You can confirm your vehicle has ABS by looking for the indicator light on the dashboard that briefly illuminates when you start the vehicle. The ABS warning light usually appears as the letters "ABS" inside a circle on the dashboard.

While your brakes will still function if the ABS light is on, the anti-lock feature might be disabled, which means you will lose the ability to maintain steering control during hard braking. This significantly increases risk.

You can drive to a repair facility, but do so with care to avoid any situations that call for emergency braking.

No, you should not pump the brakes on a vehicle equipped with ABS. The system automatically pulses brake pressure multiple times per second — faster than any driver can pump.

ABS performs exceptionally well under most circumstances, but it has some limitations. On loose gravel or deep snow, locked wheels can sometimes create a wedge effect that stops a vehicle faster than ABS. However, the steering control benefit often outweighs this sometimes shorter stopping distance.

Other Stories

EBPMS: Electronic Braking Performance Monitoring System

June 30, 2025

4 minute read

What are maintenance service intervals?

April 9, 2025

5 minute read

What are the Federal Motor Vehicle Safety Standards (FMVSS)?

January 3, 2025

4 minute read