Stop burning profits: Your guide to conquering construction fleet idling

Uncover hidden costs and actionable strategies to optimize your fleet with this essential guide.

By Geotab Team

Jul 23, 2025

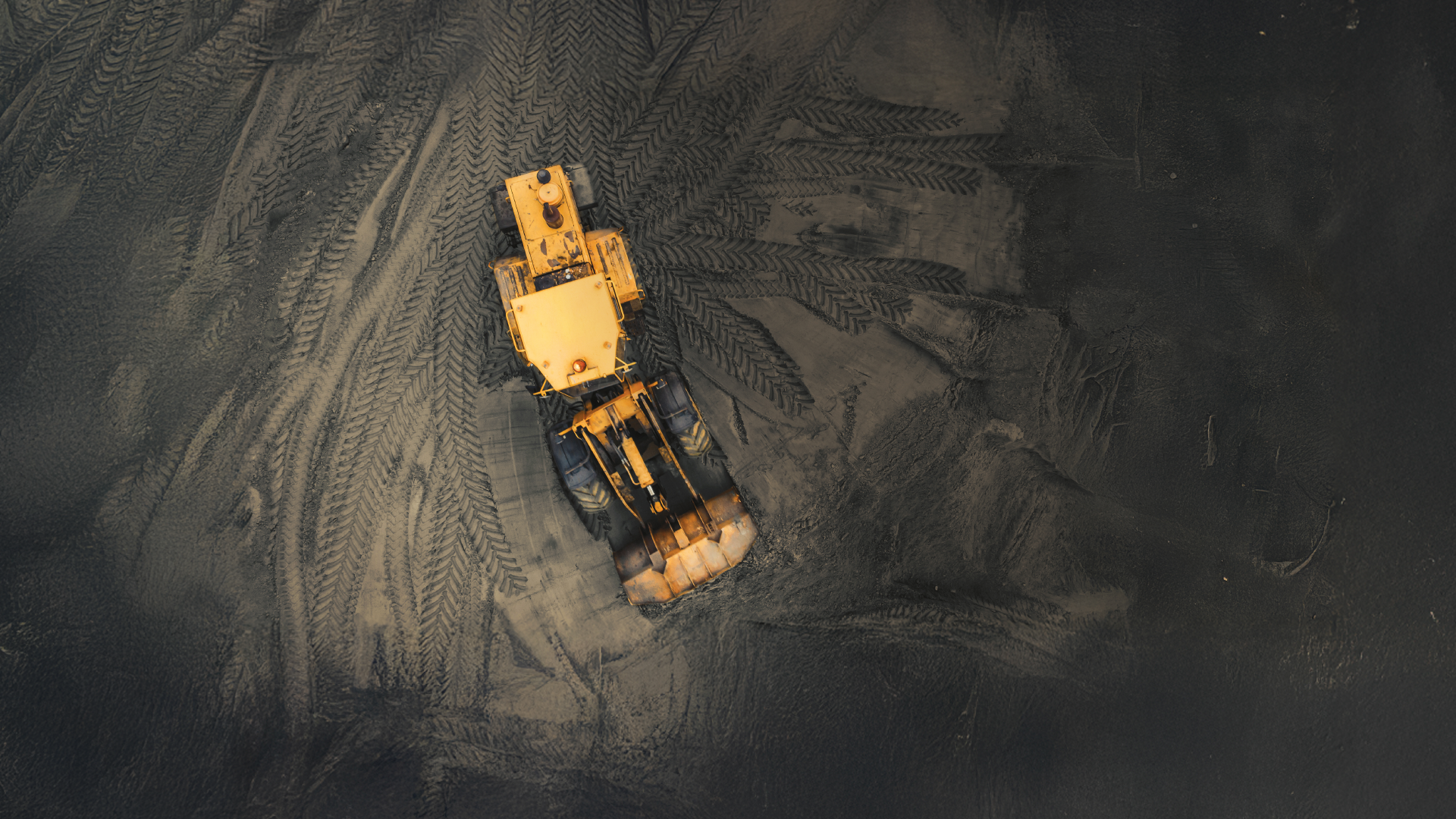

Did you know that, in the construction industry, equipment idle time averages around 30% of scheduled operating hours?

This means that your equipment is likely idling for about a third of the time. When you take into account that the average cost of idling for a typical piece of construction equipment, such as a bulldozer, is approximately $35 per hour, you realize that the costs start adding up quickly.

How can your construction fleet take the first step towards lowering your idle time and making back those precious dollars? Let’s talk about it.

Idling myth-busting

It’s normal to try to explain away idling habits, but a lot of what we conceive about idling is untrue. Let’s do some myth-busting around idling before we dive in.

Myth 1: Restarting your engine uses more fuel and causes more wear than idling.

Fact: Idling for more than 10 seconds uses more fuel than restarting the engine.

Myth 2: Idling is necessary to warm up your engine, especially in cold weather.

Fact: Most cars need only 30 seconds for oil to circulate, even on freezing days. The best way to warm up your engine and other vehicle components is to drive gently.

Myth 3: Idling is good for your engine.

Fact: Excessive idling can actually damage engine components, including cylinders, spark plugs and exhaust systems. It can also cause oil contamination and increased engine wear.

Myth 4: Idling doesn’t waste much fuel or money.

Fact: A car idling for just two minutes uses about the same amount of fuel as driving one mile.

Myth 5: Idling is only a problem in winter.

Fact: Idling is a year-round issue. In summer, idling with the air conditioner on burns even more fuel.

Myth 6: Diesel engines need to idle for long periods to warm up or prevent fuel problems.

Fact: Most modern diesel engines require no more than three minutes to warm up, and winter fuel blends have addressed fuel gelling issues.

How much is idling really costing you?

That "minor" habit of leaving engines running? Its impact is bigger than you think, hitting your construction operations from every angle.

1. Sky-high fuel bills

An idling construction vehicle can guzzle up to a gallon of fuel every hour. Now, multiply that by every truck and piece of equipment in your fleet. The numbers add up fast, turning your fuel budget into a major headache.

2. Premature wear and tear on your equipment

Idling doesn't just burn fuel; it actively harms your engines. When an engine runs without moving, it leads to:

- Fouled spark plugs from carbon buildup.

- Contaminated oil that needs more frequent changes.

- Faster wear on essential engine parts.

This means more time in the shop, higher repair bills and a lower resale value for your assets. Since buyers focus on engine hours, high idle time is a red flag that screams "excessive wear," even if the mileage is low.

3. A setback for your sustainability goals

Trying to run a greener operation? Idling is working against you. Every hour an engine idles, it pumps out carbon dioxide, nitrogen oxides, and other pollutants. Cutting idle time is a direct and powerful way to shrink your carbon footprint and build a better reputation with eco-conscious clients.

The hidden costs sabotaging your success

Beyond fuel and maintenance, idling creates problems that can slow your business down and hurt your reputation.

- Unhappy clients: When equipment is left idling, it often means delays. Tasks take longer, projects fall behind schedule and clients get frustrated. In a competitive market, that’s a risk you can’t afford. Happy customers are repeat customers, right?

- Lower asset value: As we mentioned, engine hours are a key metric for buyers. By reducing idle time, you’re not just saving on fuel — you're protecting the long-term value of your entire fleet.

Ready to fight back? Here’s your game plan.

You don’t have to guess where the problems are. It’s time to get clear, actionable insights.

1. Know where you stand with telematics

Want to know exactly when, where, and why your vehicles are idling? A telematics platform like Geotab gives you the visibility you need to take action. You can:

- Pinpoint idle hotspots: See your entire fleet's idling patterns in one place.

- Coach your team: Identify drivers who idle the most and provide targeted training.

- Get real-time alerts: Notify drivers and supervisors the moment idling exceeds your preset limits.

2. Empower your drivers to be part of the solution

Your team on the ground is your greatest asset in the fight against idling. Get them on board by:

- Showing them the numbers: Make them aware of how much idling truly costs.

- Training for efficiency: Teach simple habits, like turning off engines during breaks or loading times.

- Making it a friendly competition: Use leaderboards and rewards to encourage everyone to hit their idle-reduction goals.

3. Make your job sites smarter

A little planning goes a long way. Streamline your onsite workflows to eliminate unnecessary waiting:

- Set up designated staging areas for equipment.

- Schedule tasks to ensure a smooth hand-off from one stage to the next.

- Improve communication so operators aren't left waiting for instructions.

Stop idling, start winning

Unnecessary idling is more than just a bad habit — it's a direct threat to your profitability and growth. By putting telematics at the heart of your operations, you can transform data into decisions that save you money, streamline your projects and demonstrate your commitment to sustainability.

Ready to see how much you could be saving?

You can also download this handy checklist to get your team started right away: Stop Idling, Start Saving: A Checklist for Managing Idling Costs in Your Construction Fleet.

Subscribe to get industry tips and insights

The Geotab Team write about company news.

Table of Contents

Subscribe to get industry tips and insights

Related posts

Telematics trends for 2026: What is changing and how fleets can respond

January 30, 2026

6 minute read

Fleet GPS tracking systems cost: Full price breakdown and ways to boost ROI

January 30, 2026

6 minute read

Fleet operations: Key components, benefits and challenges

January 7, 2026

4 minute read

.jpg)

10 best fleet management software to boost performance and cut costs

December 22, 2025

8 minute read

The $4B Crisis: Video Intelligence as the Answer to Fleet Distraction

December 2, 2025

3 minute read