How to stop wasting mechanic hours on ‘ghost codes’ and low-priority repairs

Hiring isn't the only solution to technician shortages. Learn how to unlock hidden capacity in your shop to speed up repairs and minimize downtime.

By Geotab Team

Feb 2, 2026

Key Insights

- Your labor shortage could be just trapped capacity if 20% of your shop time gets burned on nuisance alerts, duplicate faults and admin. Fix your workflow first. Hiring won’t outrun wasted hours.

- You can stop “No Fault Found” events with better filtering. Filtering fault alerts under ~30 seconds and requiring repeat/persistence reduces your shop load and keeps vehicles earning.

- Running your shop first in, first out creates major bottlenecks. Prioritizing maintenance by severity and auto-creating work orders makes sure your techs are working efficiently on the top-priority repairs.

Yes, the technician shortage is real, but what if you could get more productive hours from your existing maintenance crew? It seems inevitable that mechanics waste an hour here or there focusing on low-priority items while more urgent repairs wait in the queue. But it doesn’t have to be this way.

In many fleet operations, up to 20% of shop hours get burned on two killers:

- False alarms directly hit revenue when they pull vehicles off the road for minor issues — or worse, non-issues.

- Bottlenecks in your shop create avoidable delays when critical repairs get stuck behind minor fixes.

By cleaning up your maintenance workflow and fault management, you can maximize your effective output without hiring a single new mechanic.

Here’s your guide to increasing maintenance capacity.

1. Filter ‘ghost codes’ to stop revenue bleed

Manually following up with every vehicle fault code — or ignoring faults because your capacity is maxed — is not a viable option for a competitive fleet. Every time you pull a vehicle off the road for a glitch, the time and costs mount: dispatch reshuffle, possible tow, technician diagnosis, bay occupancy. And worst of all, the job doesn’t get done.

- The problem: Modern vehicles are packed with sensors that can throw transient faults from voltage dips, connector vibration, temperature swings or a momentary data drop. Suddenly you get a “check engine” event that isn’t repeatable. That’s a ghost code: a fault that appears long enough to trigger an alert, then disappears before anyone can validate it.

- The fix: Intelligent fault filtering allows you to treat short-duration faults as noise until they prove they’re real. This way you get fewer unnecessary road calls, fewer “no fault found” tickets and more vehicles staying on revenue routes.

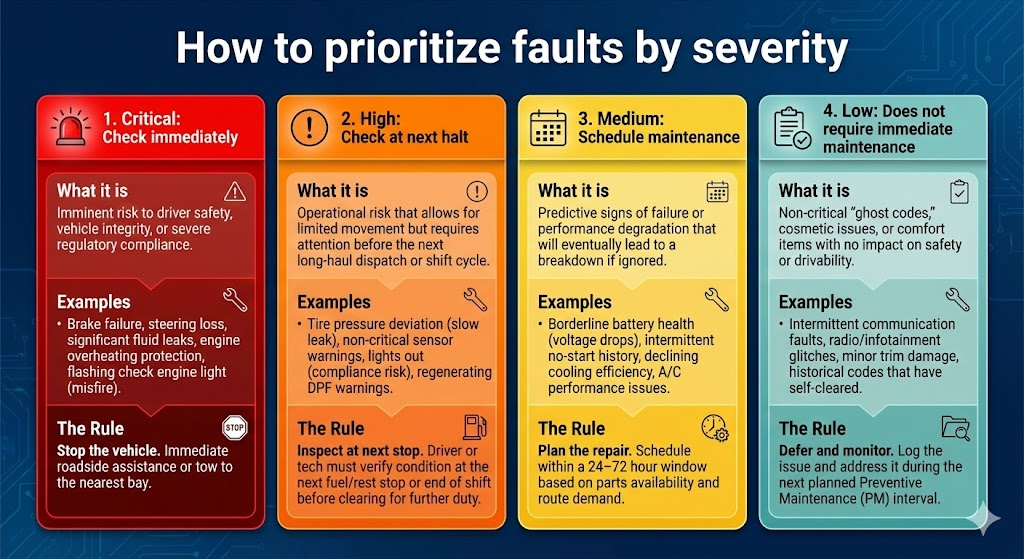

2. Prioritize faults by severity to clear shop bottlenecks

Running your shop first-in, first-out means important vehicles sit idle because the schedule is clogged with non-essential maintenance. Adding to the difficulty, when a vehicle comes in with an ambiguous engine fault, mechanics under time pressure may resort to guessing at parts, swapping components to see what sticks and tying up bays hoping for a fix.

- The problem: A lot of shops still run on a first-in, first-out basis, but FIFO lets small, low-impact issues consume bay space while high-impact issues wait in line. A vehicle with a broken interior light or a minor sensor warning should not block a unit with braking concerns or coolant loss.

- The solution: Severity-based triage with clear service levels sorts faults before the vehicle enters the shop. You ensure your mechanics are only using expensive parts on confirmed failures. Critical assets spend less time waiting and overall fleet downtime drops.

3. Automate the admin to reclaim wrench time

Every minute a technician spends typing up a report, deciphering a driver’s handwritten DVIR or looking up a part number is a minute they aren't fixing a vehicle.

- The problem: Your highest-paid labor is doing low-value work — writing up reports, copying codes, chasing unit history and decoding handwritten notes. That’s administration, not maintenance. And it’s not the best use of tech time.

- The solution: An open telematics solution that can automatically create work orders from validated fault events and send them directly to your preferred maintenance system. Your technicians see the context, recommended checks and parts notes and they are ready to go.

Efficiency is your new headcount

The fleets that win in 2026 won’t be worrying about a mechanic shortage because they’ll be using data to eliminate waste and make their existing labor force more efficient.

Telematics systems that integrate with your existing tech stack can filter ghost codes, prioritize fault severity and automate work orders, unlocking hundreds of technician hours. By fixing only what’s actually broken, you protect your revenue by keeping healthy vehicles moving and you cut your parts budget.

Ready to build this automated workflow?

Download our new guide, How to make maintenance your fleet’s competitive advantage, for the complete blueprint on shifting from reactive repairs to predictive reliability.

Subscribe to get industry tips and insights

The Geotab Team write about company news.

Table of Contents

Subscribe to get industry tips and insights

Related posts

Collision avoidance systems: How fleets prevent incidents and improve safety

December 23, 2025

5 minute read

.jpg)

.jpg)

Go beyond reactive truck maintenance with predictive solutions that drive profits

December 8, 2025

3 minute read

The $4B Crisis: Video Intelligence as the Answer to Fleet Distraction

December 2, 2025

3 minute read