A complete guide to fleet idling: Understand, detect and stop true idling

Idling increases fuel consumption, CO2 emissions, and maintenance costs. Learn how to control it to lower your fuel spend and make your fleet more sustainable.

By Geotab Team

Dec 15, 2023

Updated: Jun 2, 2025

Despite what you may have heard, turning off your car or truck and then restarting it does not burn more fuel than leaving it running. Some drivers leave their vehicle idling without even thinking about it. For example, an employee waits in their car for a coworker at a local coffee shop, the engine humming in the background. Excessive idling pollutes the air, waste fuel, and causes excess engine wear. Targeting this area can provide significant cost savings for your fleet, and improve its sustainability performance by reducing harmful tailpipe emissions.

True idling versus operational idling

When operating in winter conditions of below zero degrees Fahrenheit, diesel truck engines need seven minutes to increase the temperature of the combustion chamber before operating, although this time can be reduced with the use of built-in block heaters that keep the engine warm overnight. Between zero and fifty degrees Fahrenheit, idling time should be reduced to between three and five minutes. When the temperature exceeds 50 degrees Fahrenheit, diesel engines need just one or two minutes to warm up. Any more than this puts excessive strain on the engine.

Meanwhile, passenger vehicle original equipment manufacturers (OEMs) recommend against idling modern engines, and the catalytic converter warms up much faster when the car is being driven than when idling.

Understanding the difference between true idling and operational idling is helpful to managing this area of your fleet operations.

Operational Idling | True Idling |

| Definition: When a stationary vehicle is running to power external equipment, or to warm up a vehicle to legal limits. | Definition: When a vehicle’s engine is running, but the vehicle doesn’t change position. |

| Examples: Idling with a PTO unit to run equipment such as a high-powered vacuum, snow plow, dump deck, or a towing mechanism on the back of a truck bed. | Examples: Idling while in stop-and-go traffic, drive-through lines, loading docks, or depots. Or running the vehicle engine to power heating, air conditioning, and electronic devices while stationary. |

How does idling harm vehicle engines and systems?

According to Popular Mechanics, idling can strip oil away from the engine’s pistons and cylinders, causing it to age prematurely. Modern engines have fuel consumption regulating sensors, and idling doesn’t warm the engine well enough to enable the sensors to respond, as the fuel to air ratio is too rich. The life of components like piston rings and cylinder liners can be significantly reduced when fuel washes away the lubricating oil while the engine runs rich during idling.

The economic, health and environmental effects of idling

According to an U.S. Environmental Protection Agency, (EPA) an idling truck diesel engine will consume 0.8 gallons of fuel per hour. It calculates that twenty-five trucks idling two hours a day will burn forty gallons of diesel. With an average price of diesel of $3.20 per gallon in November 2023, this costs a fleet $128 per day in fuel for zero miles driven. Over 300 operating days, that leaves $38,400 of potential savings by reducing idling.

Diesel exhaust contains many human health-impacting pollutants such as carbon monoxide, volatile organic compounds, nitrogen oxides, and particulate matter. These pollutants are linked to a number of conditions including allergies, heart problems, asthma, lung cancer, and premature death. Since children’s respiratory systems are still developing and they have a faster breathing rate, they are more susceptible to these health conditions than adults.

An idling diesel truck emits 18 pounds of CO2 per hour, along with pollutants that also contribute to ground level ozone, smog, acid rain, and climate change. All of these emissions can be reduced by preventing unnecessary idling.

The impact of overnight idling

According to the North American Council on Freight Efficiency (NACFE), a trucker that keeps their engine idling for between five and eight hours overnight to keep their cabin warm as they sleep contributes 24,000 pounds of CO2 to the atmosphere each year and burns an additional 1,200 gallons of diesel fuel, which at today’s diesel prices costs the fleet about $3,800 a year.

Since there are about 1.7 million truckers in the United States, that equates to approximately 41 billion pounds of CO2 emitted, and 2 billion gallons of fuel consumed by idling while truckers sleep. Auxiliary power units (APUs) can eliminate the need for excessive idling and alleviate the load on the engine.

Control idling to reduce your organization’s carbon footprint

Aside from reducing your fuel costs, idling control is an important mechanism for reducing your organizational carbon footprint. The fuel used by the vehicle fleet can represent a significant proportion of an organization’s scope 1 carbon emissions (those that are directly emitted by owned or leased assets and equipment), and so any improvements made to fleet fuel efficiency can have a notable effect on the overall footprint. It may also impact your ability to pass smog checks.

While many light-duty fleets are making long-term plans to transition to electric vehicles to completely remove the fleet’s impact on their scope 1 emissions, idling is one of many fleet efficiency areas that can be addressed with immediate gains to reduce the carbon emissions associated with the current fleet.

A fleet of 25 trucks that reduces idling by 2 hours per vehicle per day stands to reduce emissions by 106 metric tons of CO2 per year (based on 300 operating days).

Strategies to reduce idling, save costs and improve your environmental performance

Reducing unnecessary idling is a great first step to reducing costs while making your fleet more sustainable as it can significantly impact fuel economy and CO2 emissions. You can manage your fuel usage by using a fuel management system.

Monitoring idling trends

To fully understand the consequences of idling, you can monitor both the amount of emissions produced and the cost of wasted fuel. It can be valuable to monitor idling trends over time to see how rates are affected by the changing seasons. If fleet idling increases significantly in the winter months, then investments in warming technologies may prove beneficial. Air heaters and waste-heat recovery systems can be used to keep vehicle cabs warm, while coolant heaters can be utilized to keep engines warm, reducing the impact of cold starts.

Comparing idling rates between vehicles helps to identify outliers that are in need of management. This can highlight vehicles that would benefit from auxiliary power systems to provide cleaner stationary power than engine idling, or drivers that are in need of additional anti-idling training.

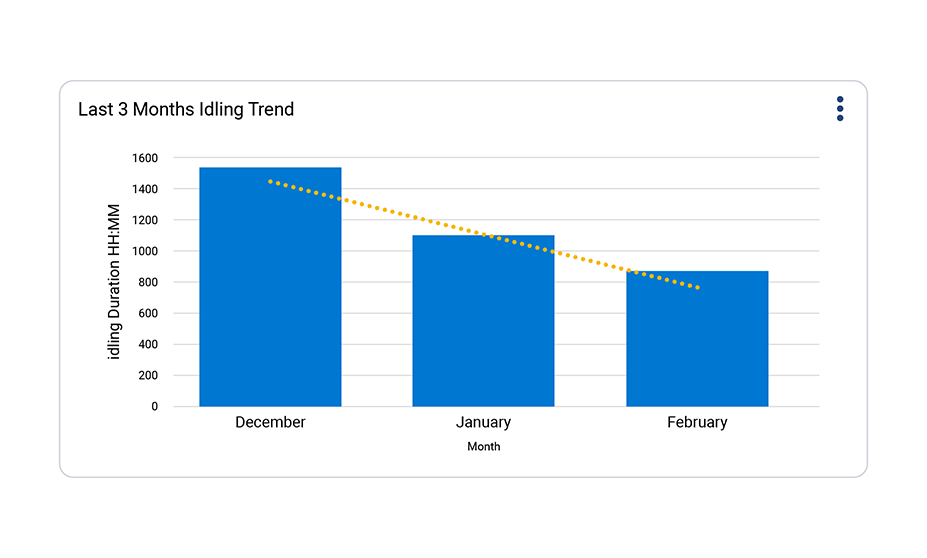

The Geotab Marketplace provides some custom report templates to help you measure your fleet’s true idling rates and exceptions. The Last 3 Months Idling Trend report displays the total idling time for the entire fleet over the last three months, and the Trended Exception Report compares drivers against each other and against daily or weekly trends.

Last 3 Months Idling Trend Report

Success story – Tracking idling trends to improve environmental performance

Wiseway, a provider of plumbing, electrical and lighting supplies in Ohio and Kentucky, achieved a 44% reduction in idling and associated CO2 emissions by using their MyGeotab telematics data to monitor idle hours trends and average idling per vehicle. This enabled them to direct training and feedback at drivers with higher idling rates to reduce fuel costs and improve their fleet’s environmental performance.

Read the full story here.

Driver awareness and training

Idling is usually a state that the driver has chosen to put the vehicle in, so driver awareness and training are key. By implementing an eco-training program, you can ensure that drivers and vehicles are operating at optimal efficiency and provide your drivers with the tools they need to operate their vehicles in a clean and safe manner.

Instantaneous driver feedback can be particularly valuable, since it highlights the behavior in the moment and causes the driver to make immediate adjustments. This can be in the form of in-cab alerts that are triggered when an idling event exceeds a customized threshold.

Another methodology that is gaining traction with fleets is to implement an element of friendly competition between drivers around idling. This can take the form of league tables for monthly idling rates, or prizes and incentives for drivers with the most improved idling rates.

Success story – Gamification as a means to reduce idling

In an effort to reduce idling, the international pest control and home services company Orkin took a creative approach and set up an internal competition. They monitored each driver’s total idle time in MyGeotab, and awarded the drivers with the lowest and most improved idle times. Over a three-month period, they were able to reduce fleet-wide idling by 8.4%, saving an estimated $50,000 in fuel costs. This initiative was a win-win that improved Orkin’s corporate image, environmental performance and bottom line.

Read the full story here

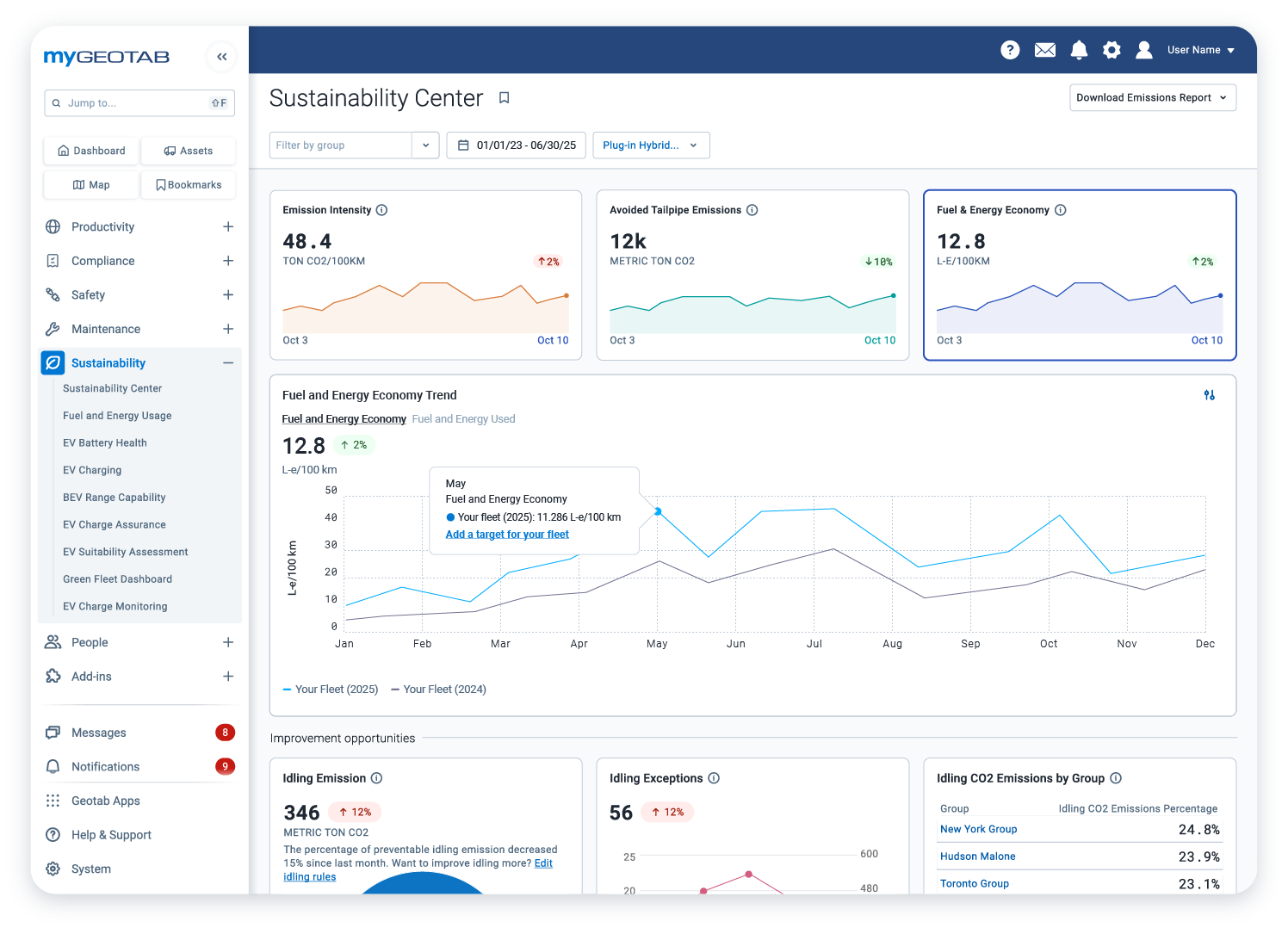

Monitor the impact of your anti-idling strategies on your carbon emissions

The Sustainability Center enables companies to optimize fleet operating costs and environmental performance, isolating the factors that contribute to excess fuel use so that you can manage the reduction of fleet emissions and improve fuel efficiency. It also provides actionable insights, such as a ranking of fleet groups based on fuel wasted and emissions produced from idling, in order to identify improvement opportunities.

Idling is one of many fleet optimization practices that can reduce fuel consumption, cut costs and support your sustainable fleet goals. To learn more, check out our ebook Driving down emissions: The road to a more sustainable fleet today.

This article was first published on April 29, 2022.

Subscribe to get industry tips and insights

The Geotab Team write about company news.

Table of Contents

Subscribe to get industry tips and insights

Related posts

9 strategies to increase fleet fuel efficiency and lower fuel costs

July 8, 2025

4 minute read

Creating a fleet safety culture that’s built to last: Lessons from Missouri DOT and NYC

July 7, 2025

8 minute read

Field service is losing money to bad data: Go beyond GPS with smarter telematics

June 27, 2025

3 minute read

Enhancing winter road maintenance with postseason materials usage analyses

June 20, 2025

6 minute read

Building a self-sustaining school bus driver safety program with Geotab Vitality

June 13, 2025

7 minute read