Cold chain logistics: 2025 guide for fleet managers

Cold chain transportation helps maintain product integrity for perishable or temperature-sensitive items, such as fresh food, pharmaceuticals and chemicals — and helps you meet strict regulatory standards.

By Geotab

Nov 28, 2025

Key Insights

- Cold chain logistics relies on temperature-controlled storage, specialized packaging, refrigerated transportation and real-time monitoring.

- Maintaining consistent temperatures, ensuring regulatory compliance and managing equipment reliability are significant challenges in cold chain logistics.

- Implementing fleet management software enhances cold chain operations by providing real-time monitoring, optimizing routes, ensuring regulatory compliance and improving overall efficiency.

A reliable cold chain ensures perishable products such as pharmaceuticals remain safe and effective throughout the journey. This is where cold chain logistics comes into the picture. It involves transporting and storing temperature‐sensitive goods, preserving product integrity from origin to destination.

Explore more about cold chain transport, the components involved in the process, common challenges and the benefits of using fleet management software. We will also discuss ways to improve your cold chain trucking logistics and tips for optimizing it.

What is cold chain logistics?

Cold chain logistics is a specialized, temperature-sensitive logistics process that ensures products stay within a specific temperature range during delivery. Its main components are refrigerated storage, transport and packaging.

Cold chain transportation helps maintain product quality for perishable or temperature-sensitive items such as fresh food, pharmaceuticals and chemicals. It also helps meet strict regulatory standards.

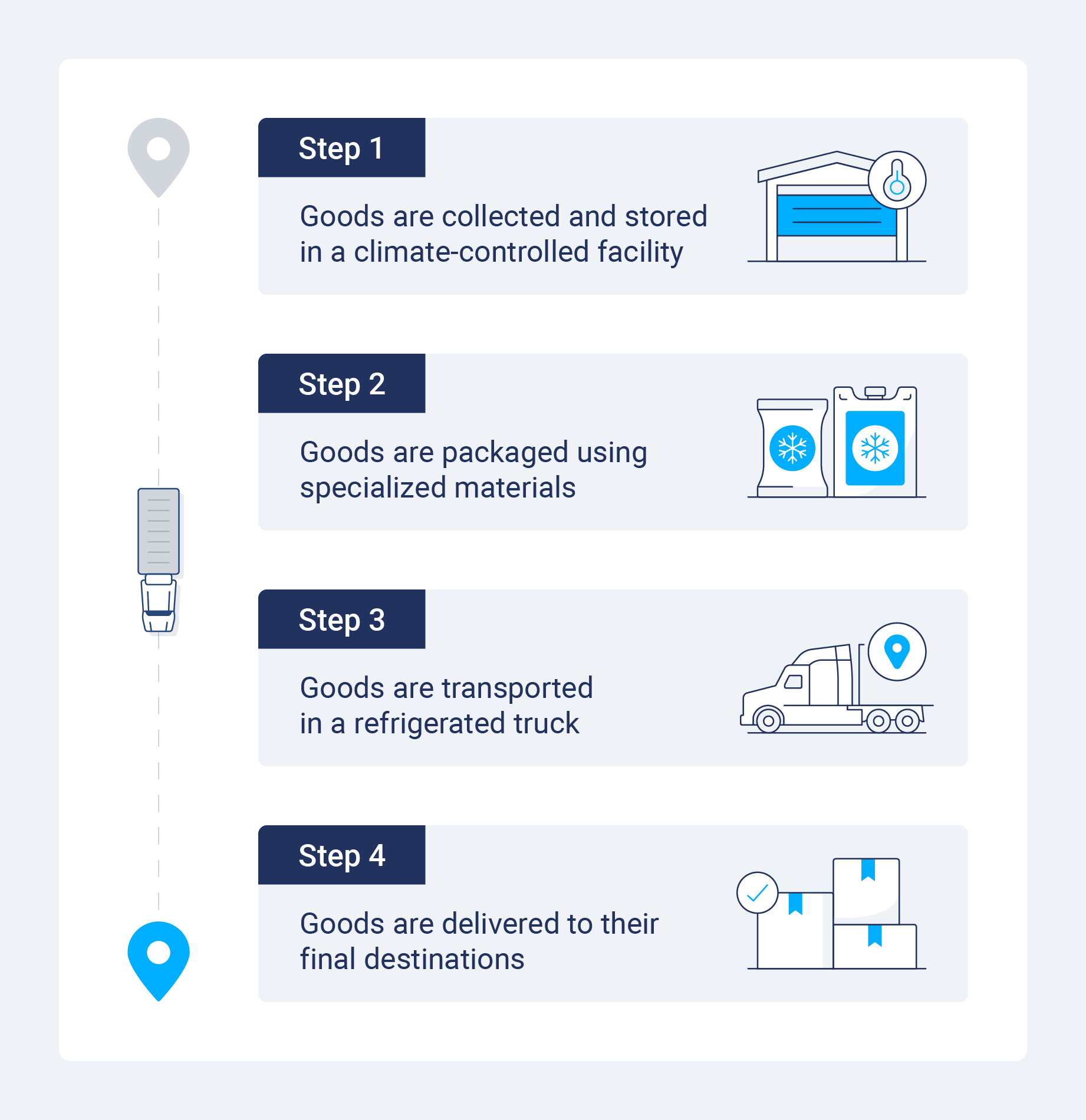

Cold chain logistics components

Cold chain logistics comprises several critical components that work seamlessly to preserve temperature-sensitive products throughout the entire supply chain. Each component — from specialized storage facilities to advanced monitoring systems — helps maintain the integrity, safety and compliance of perishable goods.

Storage

Storage is the first step in the cold chain, where products undergo conditioning in temperature-controlled environments. Dedicated refrigerated warehouses and cold rooms keep products at specified temperatures to maintain freshness and prevent spoilage immediately after production.

This foundational step ensures that all items retain quality before you further process or ship them.

Packaging

Cold chain packaging uses specialized materials and solutions to maintain consistent temperatures during transportation.

Insulated boxes, gel packs, dry ice and phase change materials are examples of such materials that create protective barriers against heat and cold fluctuations. These solutions stabilize the product’s temperature and safeguard against physical damage.

Temperature-controlled transportation

Cold chain transportation, or cold chain shipping, relies on vehicles and containers engineered to maintain precise temperature conditions.

You can use refrigerated trucks, railcars and specialized shipping containers (reefers) for transportation. These vehicles have integrated refrigeration systems that actively control the internal environment. Food transportation facts consistently highlight the importance of reliable refrigeration during transit. Even small temperature changes can lead to spoilage or contamination, especially in perishable foods. This specialized shipping mode ensures the products remain safe and effective from origin to destination.

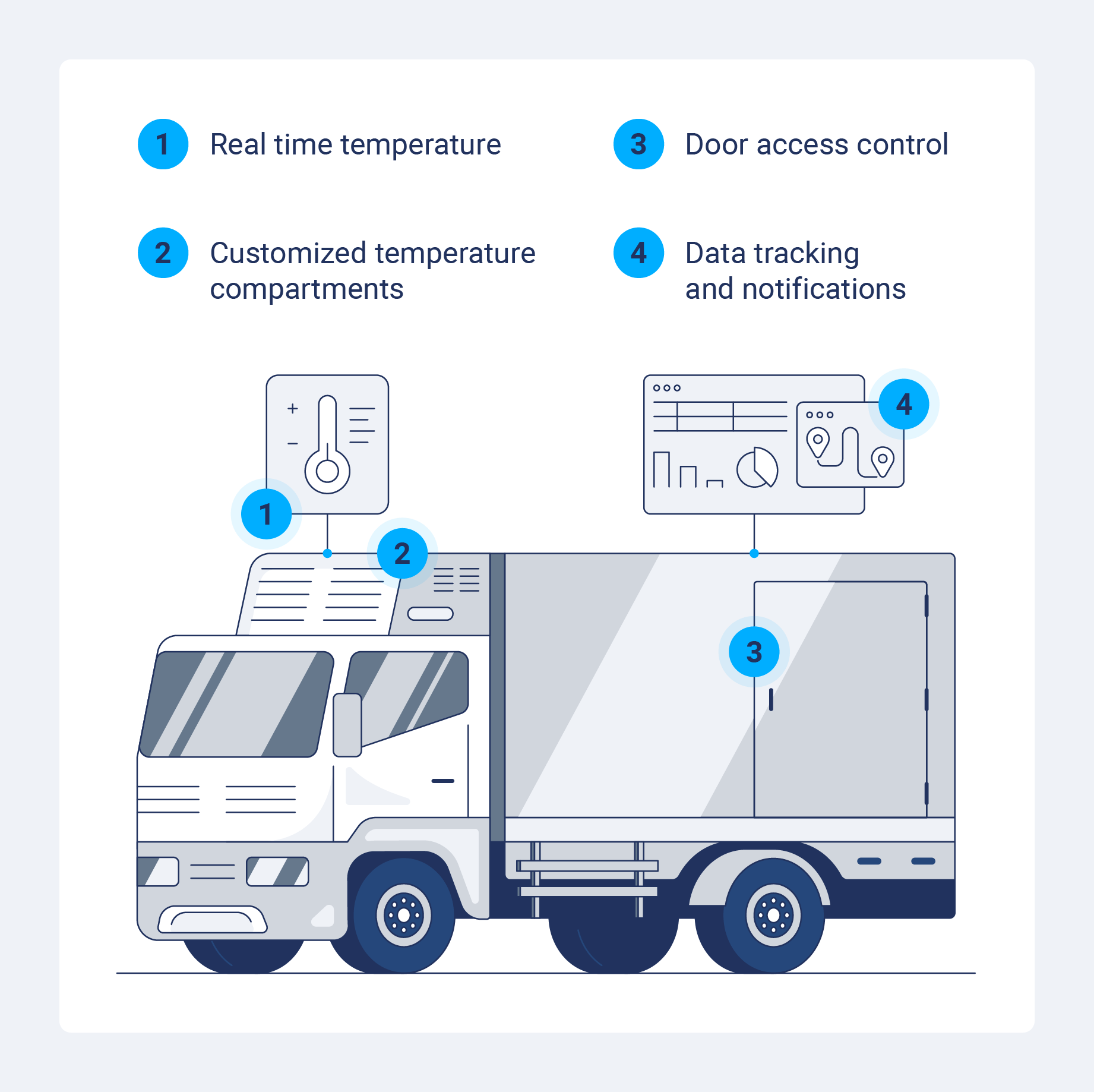

Monitoring and analytics

Effective cold chain trucking continuously monitors temperature and humidity levels using advanced technologies such as IoT sensors, radio-frequency identification (RFID) tags and digital data loggers. These real-time monitoring systems provide actionable insights and alerts, enabling quick interventions when deviations occur.

Comprehensive analytics also help maintain product integrity and support data-driven decisions to optimize storage and transportation conditions throughout the cold supply chain.

Compliance and regulations

You must follow robust documentation and quality control measures to protect product efficacy and consumer safety. Adherence to strict industry regulations and guidelines ensures that every aspect of the process complies with health and safety standards.

Some common nationwide guidelines include:

- Good Distribution Practices (GDP) for pharmaceuticals

- Hazard Analysis and Critical Control Points (HACCP) for food safety

- Food Safety Modernization Act (FSMA)

- FDA and USDA requirements

4 key challenges in cold chain logistics

Maintaining an end-to-end cold chain for temperature-sensitive goods presents several challenges that can disrupt the overall cold chain distribution process.

Choosing a solution specific to your needs can solve most problems. For instance, if you transport only food items, a food and beverage fleet management solution can be highly beneficial.

That said, you must address four major challenges to preserve product quality and ensure consumer safety.

1. Regulatory compliance

Accurate documentation and thorough reporting are essential in cold chain logistics management. Strict regulatory guidelines require detailed records at every stage to prove that products have consistently been maintained within the specified temperature ranges.

Inaccurate records might result in compliance issues, leading to recalls or penalties. Meticulous documentation also helps verify that products, especially perishable foods and pharmaceuticals, meet both domestic and international standards.

2. Weather conditions

Extreme weather conditions are a major challenge in end-to-end cold chain management. Sudden temperature fluctuations caused by heat waves, cold snaps or other climatic events can disrupt the delicate balance required for maintaining safe product temperatures.

These weather-induced variations can lead to temperature excursions, compromising product safety and quality. Your cold chain logistics management systems must be robust enough to counteract external conditions through enhanced insulation, backup power sources and reliable refrigeration technology.

3. Lack of visibility

You need real-time visibility in cold chain distribution to promptly detect and address temperature or humidity deviations. Even minor temperature anomalies can go unnoticed without immediate alerts and notifications, increasing the risk of product spoilage.

Deploy technologies that offer continuous tracking and instant communication for effective cold chain logistics management. These technologies help ensure swift corrective actions and maintain product quality.

Lead your fleet with advanced GPS vehicle tracking

4. Equipment failure

Equipment failure poses significant risks in cold chain logistics. Even brief disruptions can lead to temperature loss and product compromise. For instance, the failure of refrigeration units in trucks, railcars or storage facilities can delay deliveries and lead to a breakdown in the end-to-end cold chain.

Such unexpected events endanger product safety and result in substantial financial losses due to waste, increased maintenance costs and potential claims from customers.

Cold chain logistics tips and best practices

Here are some tips to mitigate cold chain trucking risks, optimize operations and ensure end-to-end product safety throughout the cold chain distribution process:

- Invest in temperature monitoring: Deploy IoT-enabled sensors, digital data loggers and remote monitoring systems to continuously track temperature and humidity.

- Optimize transportation routes: Analyze route options using advanced analytics and mapping tools to select paths that minimize exposure to adverse weather conditions and reduce transit times.

- Maintain temperature-controlled vehicles: Regularly inspect, maintain and upgrade refrigerated trucks, railcars and shipping containers to meet performance standards.

- Implement packaging solutions: To further protect goods during transit, utilize specialized cold chain packaging materials, such as insulated boxes, gel packs, dry ice and phase change materials.

- Establish clear documentation: Maintain comprehensive records, including temperature logs, maintenance reports and compliance documentation, at every stage of the supply chain.

- Prioritize data predictive maintenance: Use historical data and predictive analytics to anticipate equipment failures before they occur.

- Enhance staff training and communication: The trucking industry invests $14 billion in safety measures annually — and for good reason. Regular training sessions can reduce human error and boost employee safety.

The benefits of using fleet management software

Fleet management software tailored for cold chain freight offers a powerful way to optimize operations, reduce fleet management costs and ensure product integrity throughout the entire distribution process.

These systems integrate real-time monitoring, intelligent route planning and automated compliance tools to help you deliver products safely while boosting overall efficiency and customer satisfaction.

Here are some key benefits of using a fleet management solution:

- Reduced product spoilage: Advanced systems continuously monitor temperature and other critical factors, enabling immediate corrective action when issues arise.

- Increased efficiency: Automated route optimization and real-time vehicle tracking help reduce transit times and fuel consumption, leading to lower operational expenses.

- Enhanced compliance: A fleet compliance solution automatically logs temperature data, maintenance records and other key metrics to support stringent regulatory reporting.

- Improved customer experience: Fleet management software significantly enhances customer satisfaction by reducing delays, minimizing product spoilage and ensuring the consistent delivery of high-quality goods.

When choosing a fleet management solution, always prioritize the one that caters to your industry and needs. For instance, if your business mostly transports pharmaceuticals, choose a pharmaceutical fleet management solution.

Improve cold chain logistics with Geotab

Effective cold chain logistics is a task, but a transportation and logistics fleet management solution can simplify the process.

Geotab offers a comprehensive solution for real-time temperature monitoring, ensuring temperature-sensitive goods stay within specified ranges throughout transportation.

You’ll have access to live data on cargo temperatures, refrigeration unit status and door activity, enabling you to take immediate corrective actions if deviations occur.

Subscribe to get industry tips and insights

Frequently Asked Questions

Cold chain logistics refers to transporting and storing temperature-sensitive products under controlled conditions to maintain their quality and safety throughout the supply chain. This process is crucial for perishable goods like food, pharmaceuticals and chemicals.

The two primary types of cold chain are:

- Refrigerated (chilled) chain: Maintains products between 0°C and 8°C — suitable for items like fresh produce and dairy.

- Frozen chain: Keeps products below 0°C — ideal for frozen foods and certain pharmaceuticals.

The global cold chain logistics market was worth approximately $293.58 billion in 2023. It could grow to $862.33 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 13% during the forecast period.

The four R's of cold chain logistics are:

- Right temperature: Ensuring products are kept within specified temperature ranges

- Right place: Delivering products to the correct location

- Right time: Making timely delivery to maintain product integrity

- Right documentation: Maintaining accurate records for compliance and traceability

Geotab team

Table of Contents

Subscribe to get industry tips and insights

Related posts

Best ELD for trucks: Top devices for compliance and safety [2026]

December 18, 2025

6 minute read

.jpg)

Go beyond reactive truck maintenance with predictive solutions that drive profits

December 8, 2025

3 minute read

Best ELD for owner operators: Top 6 picks and how to choose one

December 1, 2025

6 minute read