Fleet management costs: A complete cost analysis guide

High fleet management costs can impact not just the bottom line, but also overall efficiency. Find out how to manage and reduce fleet management costs with the help of telematics and connected vehicle technology.

Dec 3, 2024

Updated: May 2, 2025

Key Insights

- Fleet management costs include both the total cost of ownership and the operational costs.

- Both renting and owning fleet vehicles have merits, with renting being more expensive long-term and owning being more expensive up-front.

- Fleet management software can help reduce fleet management costs with telematics data that enables users to monitor driver behaviors, schedule maintenance and reduce idle time.

Increasing vehicle acquisition costs, skyrocketing fuel prices, rising maintenance costs and insurance all contribute toward surging fleet management costs which show no signs of slowing down. Forecasters also anticipate a demand-supply imbalance and global inflation.

Global Fleet Management predicts that operating a fleet will continue to be expensive in the years to come. Understanding these costs and looking for ways to reduce expenses is essential to saving money and improving efficiencies across the entire fleet.

Understanding fleet management costs

Fleet costs are a combination of the total cost of ownership (TCO) plus the cost of operations for the fleet. Fleet management cost analysis is essential because these expenses directly impact a company's bottom line. By effectively managing costs, businesses can improve profitability, enhance operational efficiency and maintain a competitive edge.

These costs include:

- Vehicle ownership

- Operating costs

- Fuel costs

- Driver wages

TCO includes the following:

- The starting cost of the vehicle

- The price of the vehicle when it is sold

- The costs of the vehicle between buying and selling it.

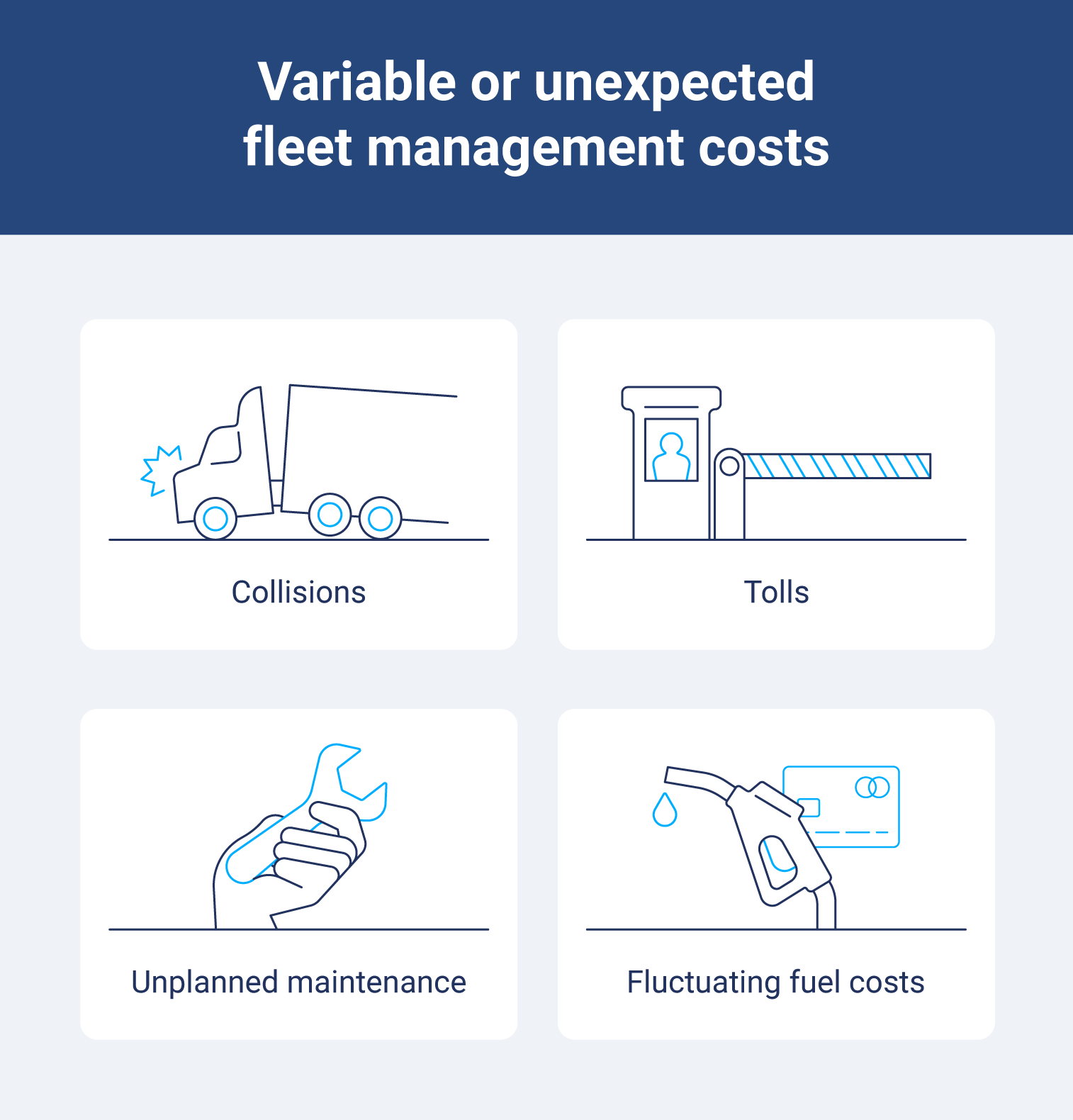

Fixed vs. variable fleet operating costs

Fleet operating costs or running costs are typically divided into two categories — fixed and variable costs.

Fixed costs such as licenses, labor charges and lease payments are long-term and generally are the same throughout the year.

On the other hand, variable costs change depending on different factors and would include unexpected expenditures such as:

- Collisions

- Unplanned maintenance costs

- Tolls

- Fluctuating fuel costs

How to calculate fleet cost per mile

Let us start with calculating the TCO, one of the highest contributors to fleet costs. There are several factors that need to be included while calculating fleet costs. They are:

- Asset acquisition

- Licensing

- Maintenance costs

- Labor and other operational costs

- Disposing of assets

Geotab previously developed a fleet-specific Cost-per-Mile (CpM) model that included sub-models for fixed, variable, and driver salary-related costs.

The variable models depended on two factors: vehicle class (the size of the fleet and type of vehicles) and vehicle mileage.

What influences fleet management costs?

Fleet management costs are influenced by a variety of factors, including vehicle ownership costs, which include things like:

- Purchase price

- Depreciation

- Financing

Operating costs such as:

- Fuel

- Maintenance

- Repairs

Indirect costs like:

- Driver salaries

- Insurance

Additionally, factors such as vehicle type, size, fuel efficiency and utilization rates can significantly impact overall costs. Effective fleet management budgets aim to optimize these factors to minimize expenses and maximize efficiency.

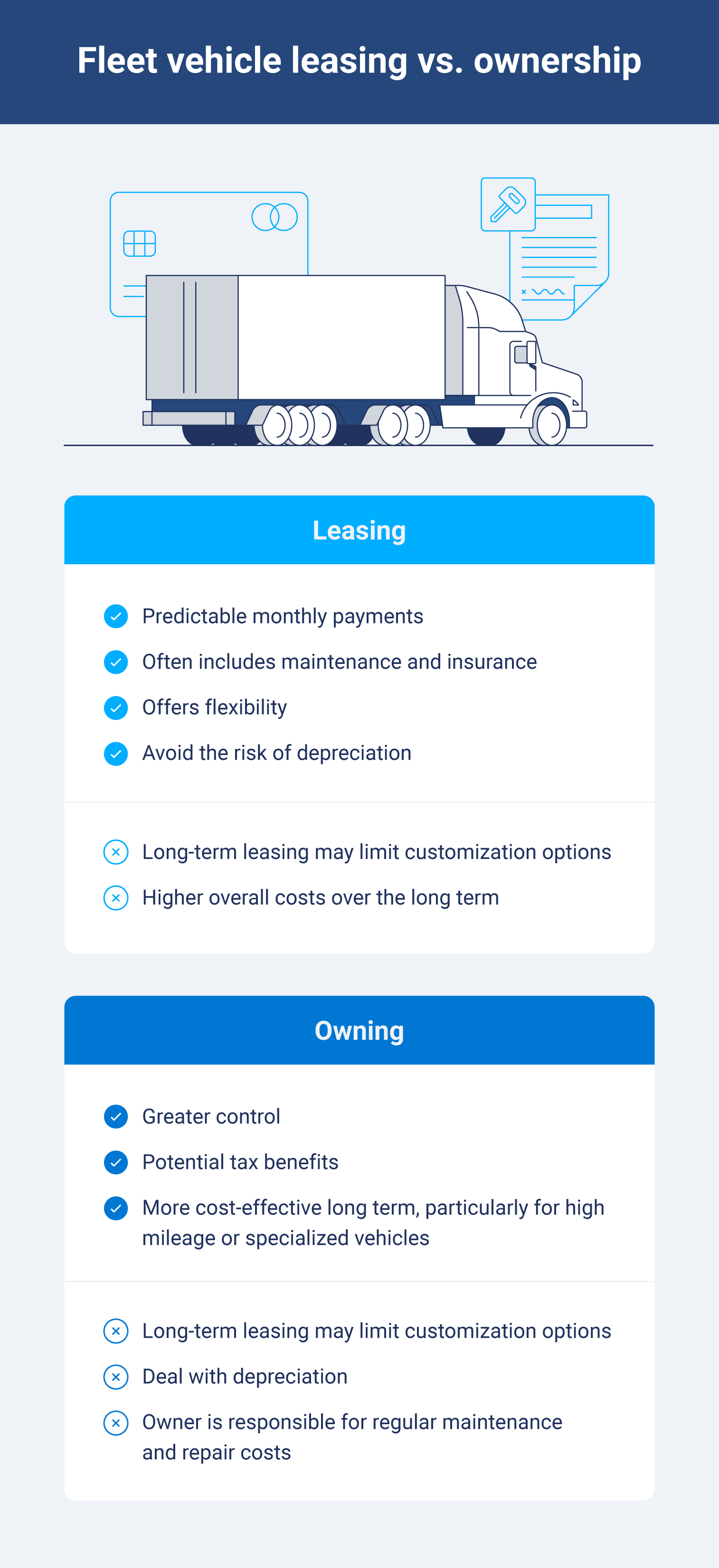

Vehicle ownership

The decision to lease or own fleet vehicles significantly impacts overall costs. Each has its pros and cons.

- Offers predictable monthly payments

- Often includes maintenance and insurance

- Can be advantageous for businesses seeking flexibility

- Can help avoid the risk of vehicle depreciation

- May limit customization options long-term

- Potentially leads to higher overall costs, especially if mileage limits are exceeded

Owning the fleet vehicles, on the other hand:

- Provides greater control

- Has a potential for tax benefits

- Includes higher initial costs

- Is more cost-effective in the long-term

- Requires regular maintenance and repairs

Operating costs

Operating costs are the ongoing and variable expenses associated with running a fleet. These costs can vary significantly depending on fleet size, vehicle type and operational requirements. Common operating costs include:

- Maintenance and repair costs associated with routine maintenance, such as oil changes and tire rotations, as well as significant repairs

- Insurance costs, including premiums for both vehicle and liability coverage

- Driver costs, such as salaries, wages, benefits and training expenses

- Technology costs, including fleet management software to track vehicle locations and fuel consumption and telematics devices

- Office space and administrative costs associated with running the office space, such as utilities and administrative staff costs

- Licensing and permit fees to the government for operating commercial vehicles

- Tolls and parking fees associated with using toll roads and parking facilities

Fuel costs

Fleet management fuel costs are a significant operational expense. While there are ways to increase fuel efficiency, such as ensuring that drivers reduce idle time, fuel is, unfortunately, one of the costs associated with all gasoline, diesel or alternative fuel vehicles unless your fleet is considering a move to electric vehicles.

Transitioning to electric vehicles comes with its own set of advantages. In addition to the obvious environmental impact, choosing EVs also helps reduce operational costs and save money in the long run. Your business will save significant money on fuel and vehicle maintenance. Moreover, there are several government initiatives for businesses that are ready to transition to electric.

Driver wages

Driver wages are a significant component of fleet operating costs. Average driver wages vary widely, depending on factors such as location, experience and the specific role. In many regions, commercial truck drivers, for example, may earn competitive wages, especially with overtime and bonuses. However, it's crucial to balance driver compensation with operational efficiency.

Fleet utilization is a key metric that measures how effectively vehicles are being used. A higher utilization rate can help offset higher driver wages. Companies can implement strategies such as optimizing routes, scheduling, and load planning to improve fleet utilization. By maximizing the time vehicles are on the road and minimizing idle time, businesses can reduce overall labor costs and increase profitability.

How to reduce costs with fleet management software

To the rescue is telematics, which plays a vital role in reducing fleet costs and improving efficiency. When Juan Cardona, VP Sales, Latin America at Geotab, spoke at the Fleet LatAm Conference 2021, he mentioned, "The return on telematics is quite immediate, maybe about a month. Fleet managers could see 15 to 20% savings on their costs. With this, they can invest in other things for their employees.

1. Utilize fleet telematics data

Telematics is changing fleet management by providing real-time data on vehicle location, speed, idle time, etc. This increased visibility enables fleet managers to optimize route planning, reduce fuel consumption and minimize downtime.

One of the most significant benefits of telematics is its ability to help reduce costs. By analyzing data on fuel consumption, maintenance expenses and driver behavior, fleet managers can identify areas for improvement and implement strategies to save money. For example, optimizing routes can reduce fuel costs while encouraging safe driving practices can lower insurance premiums.

2. Monitor driver behavior

Telematics solution provides excellent insights into driver behavior and attitude. These insights help fleet managers observe driver performance and also keep an eye out for collision data. When a vehicle collision occurs, it is important to know why and how and gather essential information for insurance and potential litigation purposes.

Reducing the premium on fleet insurance is a top priority in vehicle fleet management. One way for businesses to qualify for a premium reduction is to install a telematics device in their fleet to monitor each vehicle's trucking statistics.

A fleet tracking device can also detect harsh vehicle use, which impacts its condition over time. Harsh braking, for example, can wear down brake pads, reducing their life. By interceding with driver behavior, you can reduce bad habits that impact the life of certain parts and vehicle systems by replacing parts and providing service less frequently.

3. Schedule maintenance reminders

For a fleet, maintenance can include anything from a simple oil change or air filter replacement to a complete (Department of Transportation) DOT safety inspection. Very often, vehicles are serviced according to the three-month preventative maintenance scheduling, and then there are vehicles that are in the shop every third week. As a fleet manager, managing the predictability of vehicle maintenance helps to avoid unnecessary failures and unpredicted expenses.

By leveraging the details of telematics data, you can identify actual fleet maintenance needs and timing by picking up the actual odometer and/or engine hours off the engine, which is the most reliable source. Additionally, implementing the use of engine diagnostic reporting can help you identify maintenance patterns within certain vehicles, as well as detect and respond to problems early before they lead to costly downtime or potential safety issues.

Increase your fleet efficiency by scheduling maintenance reminders. Here’s how you can do it:

4. Decrease vehicle wear and tear

Decreasing wear and tear by reducing harsh driving improves the vehicle life cycle and the overall condition of these assets. This helps you keep disposal value high, maximizing the actual depreciation and total cost of ownership.

How do you increase fleet efficiency? Telematics tracking devices generate data that lets you assess your fleet's productivity and help you accurately determine when to increase or decrease your asset portfolio.

Regularly reviewing distance traveled or customer site visits per day could indicate a need to invest in business growth and/or identify unused assets. Unused vehicles are very expensive to tag, title and insure, so perhaps renting a vehicle for surge times or seasonal usage would be a better business decision.

5. Reduce idle time

According to the U.S. Department of Energy, an idling vehicle could cost at minimum one gallon of fuel per hour. If you do the math, you can calculate that one hour of idling per week could cost your company up to $65 per truck per year, assuming an average price of $2.50 per gallon. Fuel consumption is also impacted by load, accessories (such as refrigeration) and ambient temperature. Every vehicle in your fleet idling for even an hour a week could cost your business thousands of dollars a year.

Beyond that, excessive idling increases engine hours unnecessarily, impacts wear and tear, and increases maintenance needs, which can increase the number of oil changes and maintenance required without being more productive.

According to Telematics Wire Market research, fleet owners who effectively use telematics have reduced fuel costs by as much as 14%. Integrating fleet management into your vehicles will help you monitor and report on idling, allowing you to adjust policies for when a driver should turn off the ignition, and coach drivers to save you money. Telematics also helps with driver coaching which eventually translates into fleet savings.

To alert drivers to excessive idling, Geotab’s unique platform can be expanded to include buzzers or spoken notices of the GO TALK, reminding drivers they’re burning precious fuel. The unique open platform offered via Geotab Marketplace also lets you integrate fuel card data directly into the platform, helping you manage fuel expenses.

Get ahead of fleet management costs with a telematics solution

Geotab’s telematics data is a one-stop-shop solution that can help fleet managers explore additional revenues to reduce fleet expenses, improve the fleet's productivity, reduce the cost of ignoring or COI and better optimize their overall fleet management costs.

Learn more about optimizing your fleet with Geotab.

Subscribe to get industry tips and insights

Frequently Asked Questions

Fleet management costs encompass a wide range of expenses, including vehicle acquisition, fuel consumption, maintenance and repairs, insurance premiums, driver salaries and benefits, and administrative overhead. Additionally, businesses may incur costs related to vehicle financing, licensing and taxes.

The cost of fleet tracking per vehicle can vary widely, depending on the features, hardware and software provider you choose. Generally, you can expect to pay around $40 per vehicle per month for a basic track and trace solution. This typically includes GPS tracking, real-time vehicle location and basic reporting features.

The monthly cost of fleet management varies widely depending on factors such as fleet size, vehicle type and the specific services required. Typically, fleets can expect to pay around $40 per vehicle per month

Mrinalini Sundar is a content coordinator at Geotab

Table of Contents

Subscribe to get industry tips and insights

Related posts

Creating a fleet safety culture that’s built to last: Lessons from Missouri DOT and NYC

July 7, 2025

8 minute read

Field service is losing money to bad data: Go beyond GPS with smarter telematics

June 27, 2025

3 minute read

Enhancing winter road maintenance with postseason materials usage analyses

June 20, 2025

6 minute read