The 8 DOT inspection levels explained + DOT audit checklist

As a haulage driver or fleet owner, you must know the DOT inspection levels and what you need to do. Learn the eight DOT inspection levels with this helpful checklist.

Key Insights

- DOT audits are ad-hoc inspections that occur randomly at a variety of locations.

- There are eight DOT inspection levels, which assess the vehicle, driver and load.

- DOT inspections are not the same as annual inspections. Your annual DOT inspection does not provide you with an exemption for the DOT inspections outlined in this article.

To make the roads safer for everyone, the Department of Transportation developed an audit consisting of eight DOT inspection levels for haulage vehicles that can take place at any time.

With 10% of U.S. fatal traffic collisions involving large trucks, these impromptu inspections can help save lives, so drivers and fleet owners need to understand how to maintain compliance with DOT regulations.

This article covers every inspection level in the DOT audit, plus you can use our DOT compliance checklist to ensure you’re fully prepared at all times.

What is a DOT inspection?

DOT inspection levels are part of a DOT audit that performs routine assessments of haulage vehicles, loads and driver credentials.

The DOT audit aims to ensure driver and fleet safety, making the roads safer for everyone. It can take place anytime at locations like weigh stations, truck stops and even on the road. While there are annual audits, they don’t provide exemptions for impromptu inspections.

A DOT audit has eight different inspection levels with varying degrees of thoroughness. To help streamline these, drivers and fleet managers can use electronic logging devices that record and centralize important vehicle information.

Level 1 DOT Inspection: North American Standard Inspection

A Level 1 DOT inspection is the most thorough of all DOT inspection levels, taking about 60 minutes to complete.

Drivers must present documentation, including:

- Commercial driver's license

- Driver logs

- Skill performance evaluation certificates

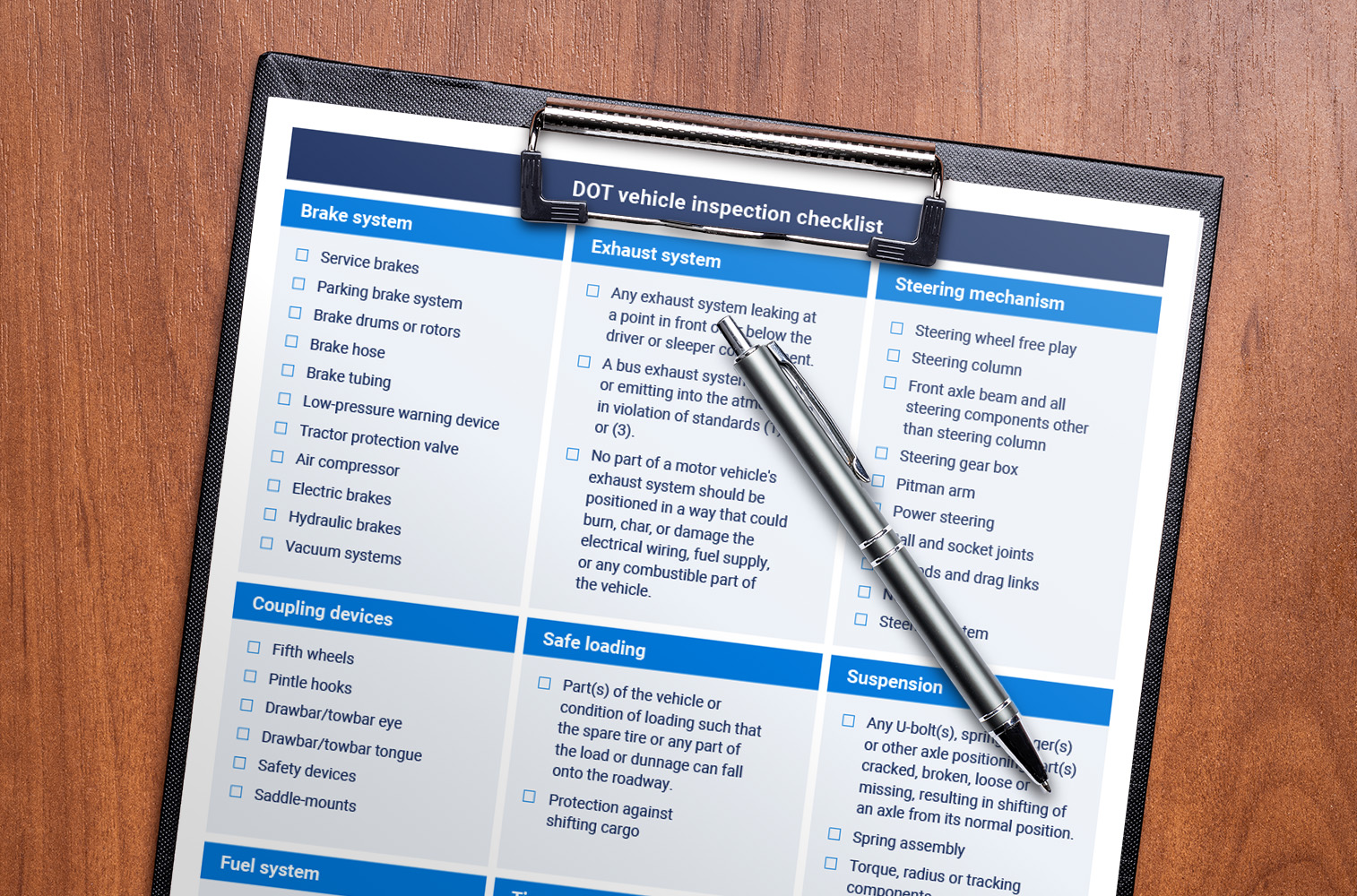

A Level 1 audit will also assess the following components of the vehicle:

- Brakes

- Seat belts

- Lights

- Steering wheel

- Suspension

- Wheels and tires

- Fuel systems

- Cargo safety

- Coupling devices

- Windshield wipers

Level 2 DOT Inspection: Walk-Around Driver and Vehicle Inspection

Also known as a Walk-Around, a Level 2 inspection contains many of the same requirements as a Level 1 inspection, except that the inspector does not check under the vehicle and trailer.

Auditors will check drivers’ drug records and histories of illegal substance use, so it’s important to keep relevant documentation on hand.

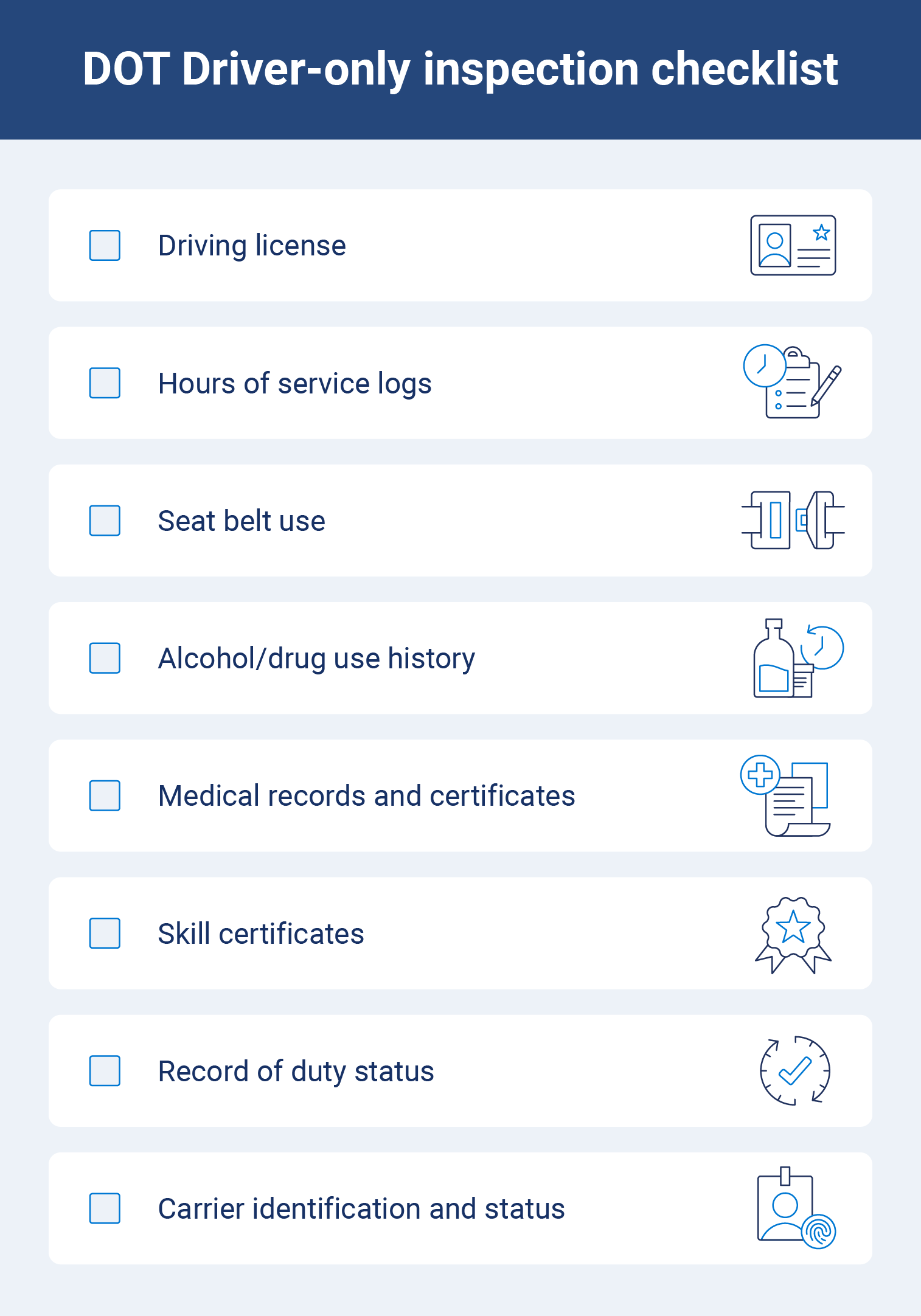

Level 3 DOT Inspection: Driver-Only Inspection

A Level 3 inspection is referred to as a driver-only inspection. It is different from a CMV inspection in that it validates driver safety rather than the vehicle's.

Typically, a Level 3 DOT inspection will warrant the disclosure of documentation, like:

- Driving license

- Hours of service HOS logs

- Seat belt use

- Alcohol/drug use history

- Medical records and certificate

- Skill certificates

- Record of duty status

- Carrier identification and status

Level 4 DOT Inspection: Special Inspection

Special audits are reserved for a very specific vehicle feature and are considered one-time evaluations. Level 4 DOT inspections can help the auditor monitor and track how a specific violation trends over time.

Keep in mind that the length can vary at the auditor’s discretion.

Level 5 DOT Inspection: Vehicle-Only Inspection

Level 5 checks have the same scope of vehicle inspections as a Level 1 DOT inspection but without driver checks. This type of check is typically done without the driver present and can be performed in any location. This is why they’re known as vehicle-only inspections.

Level 5 inspections typically take an average of 45 minutes and will likely evaluate:

- Brakes

- Fuel

- Cargo

- Steering

- Lighting

- Exhaust

- Suspension

- Tires

- Windshield wipers

- Emergency exits

- Battery

- Engine

Level 6 DOT Inspection: Enhanced NAS Inspection for Radioactive Shipments

A Level 6 DOT inspection is reserved for trailers carrying radioactive materials. It includes everything from a Level 1 inspection, plus an evaluation of radioactive materials and a radiological checking of the substances.

All haulage vehicles carrying radioactive shipments require a DOT inspection sticker. Once radiological shipments are checked, the driver will be given a special nuclear symbol that needs to be displayed on the truck until it reaches their destination. These stickers are valid for the journey in question only.

Due to the enhanced scope of a Level 6 inspection, drivers can expect such checks to take at least 60 minutes.

Level 7 DOT Inspection: Jurisdictional Mandated Commercial Vehicle Inspection

Federal DOT inspection requirements are in place for commercial vehicles within certain jurisdictions, like public transportation. As such, these inspections are within the remit of local and municipal governments rather than the DOT.

Various people may conduct them, including DOT inspection officers and public sector employees.

Vehicles commonly subject to a Level 7 federal DOT inspection include:

- School buses

- Hotel shuttles

- Shared ride transportations

- Limousines

- Public buses

Level 8 DOT Inspection: North American Standard Electronic Inspection

A Level 8 DOT inspection is conducted remotely. You will often hear this inspection called the North American Standard Electronic Inspection.

These check the location of a vehicle, driver confirmation and endorsements. This includes operating authority and feral out-of-service orders.

For a complete and compliant inspection, there must be a reliable data exchange, and drivers should have relevant records in place for verification.

A robust fleet management system can help ensure that all such data points are in place and are an integral solution to help you pass your inspection.

How to prepare for a DOT inspection

When it comes to DOT inspections, the adage of failing to plan is planning to fail applies. This means it’s fundamental that you streamline your fleet operations. The following points will help you prepare:

Prepare necessary documents

Before journeys, drivers should prepare and have all documentation to hand.

- Drivers license

- Vehicle registration

- Maintenance records

- Insurance coverage

- Driver qualifications

Fleet companies should emphasize the importance of driver vehicle inspection reports to encourage a culture of vigilance through predictive maintenance.

Organize workspace and information

Drivers should organize all their documentation and paperwork in a single folder to make it easier for DOT inspectors.

Since DOT inspections assess both the interior and exterior of the vehicle, drivers should keep their workspaces clean and organized. Not only does keeping the cab and the exterior of your vehicle clean help you look more professional during an audit, but it also helps preserve your equipment in the long run.

Digitize documents

To be safe, consider backing up all essential documents in case they are misplaced or lost in transit.

Keep in mind that physical documentation could slow down inspections and checks and is prone to being misplaced. Digitizing documents such as Hours of Service (HOS) reports and VIRSs will streamline the audit process for all parties.

To simplify the DOT audit process, use fleet management solutions that optimize the end-to-end management of vehicles and drivers.

These solutions monitor driver safety, identify missing reports and flag maintenance reports.

Most common DOT audit violations

Due to the varying DOT inspection levels, audit violations can arise for many reasons. However, some violations occur more than others. By being aware of the most common types of DOT audit violations you can be better prepared to reduce the risk of violations and fines.

The most common vehicle violations include:

- Inadequate cargo securement

- Faulty lights

- Lack of annual inspection documentation

The most common driver violations are:

- Invalid driver's license

- Exceeding HOS violations

- ELD mandate violations

To avoid hefty fines, remember to keep all of the required documentation on hand and ensure timely vehicle maintenance.

Read more: California's Clean Truck Check [2025 Fleet Manager's Guide]

Where to get your annual DOT inspection

A DOT annual inspection is a vital part of fleet maintenance. Remember, one of the most frequent failings of a regular DOT inspection is a lack of proof of an annual vehicle inspection.

Knowing where to get an annual DOT inspection is half the battle with options including:

- Truck stops

- Fleet leasing companies

- Commercial garages

- Scale houses

Ensure compliance with this free DOT inspection checklist

Failing to meet the requirements of a DOT inspection can be a costly mistake. That’s why we created a downloadable DOT checklist so that you can tick off all audit requirements before every haulage journey.

To reduce your rate of DOT violations and hefty fines, find out how fleet management solutions can help.

Subscribe to get industry tips and insights

Frequently Asked Questions

Level 1, 2 and 3 DOT inspections are the most common in that order, with the Level 1 inspection being the most thorough. Levels 4-8 are reserved for specific use cases.

The Level 1 DOT inspection is a 37-step procedure and is the most thorough of DOT inspection levels. Drivers can expect a level one inspection to take up to 90 minutes.

A Level 1 inspection conducts a 37-step procedure for both the vehicle and the driver. A Level 2 conducts the same checks as a Level 1 but without looking under the vehicle and cargo, whilst a Level 3 verifies checks with the driver only.

Yes, provided you are the owner of the truck or a company and meet the minimum requirements of a qualified annual inspector.

Failing a DOT audit can result in several penalties. This includes fines, suspension of operation and even criminal prosecution.

The next DOT/CSVA three-day inspection takes place across North America on May 13-15, 2025.

Robin Kinsey has over 25 years of sales experience in a combination of individual contributor and sales management.

Table of Contents

Subscribe to get industry tips and insights

Related posts

Field service is losing money to bad data: Go beyond GPS with smarter telematics

June 27, 2025

3 minute read

Enhancing winter road maintenance with postseason materials usage analyses

June 20, 2025

6 minute read

Building a self-sustaining school bus driver safety program with Geotab Vitality

June 13, 2025

7 minute read

The impact of unproductive idling on police vehicle service life

June 10, 2025

3 minute read

Unlock field service ROI: Your practical guide to connected operations playbook

June 9, 2025

3 minute read