Oil and gas fleet management: What to know about the industry and what’s next

Managing oil and gas fleets requires precision and visibility to meet industry demands. This guide breaks down how modern fleet solutions help operators overcome remote logistics, rising costs and safety risks while staying compliant and competitive.

By Geotab Team

Jul 30, 2025

Key Insights

- Oil and gas fleet management uses digital tools to improve visibility, safety and efficiency across remote and rugged operations.

- Fleets face challenges like downtime, high idle time, labor shortages and complex compliance requirements.

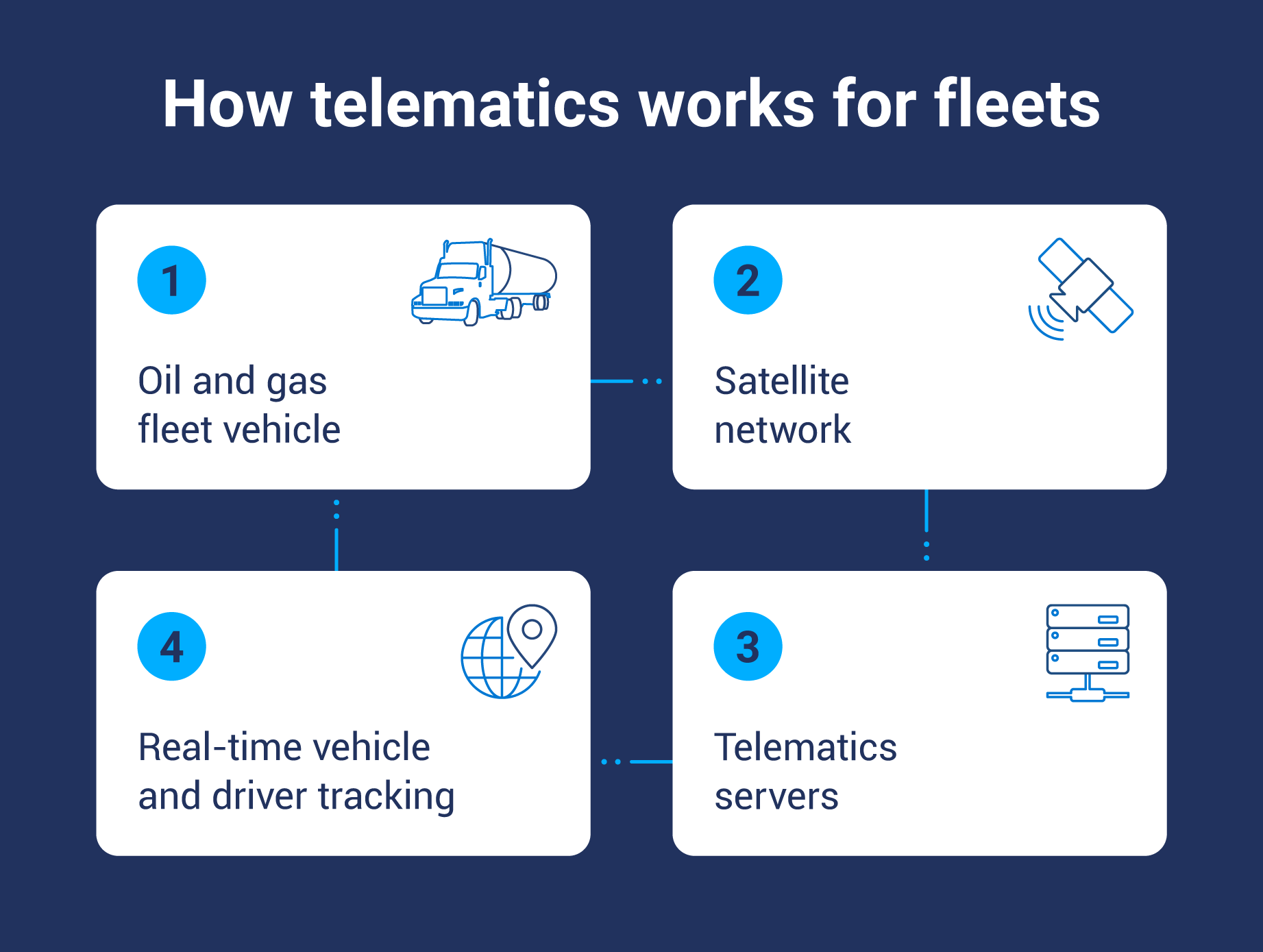

- Telematics helps reduce fuel costs, prevent equipment failure and monitor driver behavior in real time.

- Starting with scalable, integrated solutions makes it easier to digitize operations and unlock long-term ROI.

The oil and gas industry depends on vast, complex fleets to power exploration, production and delivery. With operations spread across remote regions and hazardous worksites, even small disruptions can have major ripple effects.

Oil and gas fleet management uses advanced digital tools like telematics and real-time tracking to monitor, maintain and optimize vehicles, equipment and assets. In high-risk, remote environments, even minor downtime or inefficiency can cost thousands per hour.

Digital oversight helps reduce these risks and cut operating costs. To help operators realize this potential, we’ve gathered expert insights from Jenny Koschanow, Senior Segment Marketing Manager at Geotab.

In this guide, you’ll learn about the biggest challenges oil and gas fleets face, how to manage them effectively, the role of telematics and asset tracking and strategies to improve uptime and control costs.

What is oil and gas fleet management?

Oil and gas fleet management is the process of overseeing all vehicles, equipment and assets used across exploration, drilling, production and transportation.

Unlike general fleet management, oil and gas operations require tools that can withstand harsh environments and maintain visibility over assets spread across vast, remote regions.

“Oil and gas companies leverage telematics and asset tracking to manage complex logistics and enhance efficiency across their operations,” Koschanow explains.

“The goal is to maintain visibility over dispersed assets while meeting strict safety and compliance standards.”

— Jenny Koschanow, Senior Segment Marketing Manager at Geotab

Top challenges for oil and gas fleets

Fleet management for oil and gas comes with a variety of significant operational challenges, including:

![challenges-for-oil-gas-fleets.png [alt text]: the cost of oil and fleet challenges like idle time, downtime and regulatory compliance violations.](https://www.geotab.com/CMS-Media-production/Blog/NA/2025/July/oil-gas-mining/challenges-for-oil-gas-fleets.png)

Harsh and remote environments

Oil and gas operations often take place in rugged, remote regions where fleets face extreme weather, limited infrastructure and challenging terrain. These environments can lead to equipment breakdowns, delayed maintenance and serious accessibility issues.

In these conditions, route optimization becomes far more than a cost-saver — it’s a critical part of safety and efficiency. Unlike urban or long-haul routes, oil and gas fleets must account for:

- Off-road navigation, including lease roads, unpaved access points and shifting terrain

- Road and bridge restrictions based on vehicle weight or hazardous materials

- Dynamic job site locations that change daily or weekly

- Weather-related hazards like flooding, icy roads or sandstorms

Regulated routes for hazardous material transport, which often require special permits or approved corridors

| Pro tip: Digital tools with real-time GPS tracking, weather overlays and custom map layers can help dispatchers quickly adapt to changing conditions, reroute drivers and reduce time spent in dangerous or inefficient zones. |

Difficult asset and equipment management

Oil and gas fleets are complex, consisting of light- and heavy-duty vehicles, specialized equipment and non-powered assets.

Koschanow adds that tracking this diverse mix in harsh environments is difficult and can lead to risk of theft, underutilization and breakdowns. These issues are exacerbated when assets move frequently across remote sites without centralized visibility.

| Pro tip: Deploy rugged asset trackers for non-powered equipment and use asset utilization reports to identify underused resources. Integrating telematics into a centralized dashboard helps prevent double-booking and ensures timely maintenance, improving operational efficiency. |

Idle time and fuel consumption

High idle times are a primary concern for fleets, leading to wasted fuel, increased emissions, unnecessary equipment wear and significant costs.

Idle time can be particularly high in oil and gas due to long on-site waits, equipment warm-up in cold climates or inefficient routing. Geotab's solutions can reduce idle time by up to 20%.

| Pro tip: Use telematics to generate idling reports and set real-time alerts for excessive idle time. Pair that with driver coaching and automated idle shutdown features to reduce fuel waste and engine strain. |

Downtime and maintenance

Unplanned downtime from equipment failure is a major source of lost production and high costs. “Many operators underutilize predictive maintenance tools that could prevent these disruptions,” Koschanow adds.

With some downtime costing fleets up to $760 a day, catching mechanical issues before they escalate is critical for protecting productivity and safety.

| Pro tip: Enable predictive maintenance by monitoring engine diagnostics, fault codes and usage patterns in real time. Set up automated maintenance schedules and alerts to ensure timely servicing and reduce costly breakdowns in the field. |

Regulatory and safety compliance

The industry operates under strict health, safety and environment (HSE) and emissions regulations. Failure to comply can lead to hefty fines and operational delays. According to OSHA, there’s a maximum fine of $16,550 per violation. In 2023, OSHA issued $1.6 million in penalties to the oil and gas sector.

Oil and gas fleets must navigate an evolving compliance landscape, including:

- U.S. Department of Transportation (DOT)

- Hours of Service (HOS) and electronic logging device (ELD) mandates to prevent driver fatigue

- Hazardous materials regulations (HMR) for the safe transport of fuels, chemicals and flammable substances

- Environmental Protection Agency (EPA)

- Mobile source emissions standards regulating NOx, PM and GHG emissions from diesel vehicles

- Spill Prevention, Control, and Countermeasure (SPCC) rules requiring detailed oil spill prevention plans for facilities and fleets

- California Air Resources Board (CARB) for operations in or traveling through California

- Advanced Clean Fleets and Truck & Bus regulations requiring emissions reporting, zero-emission vehicle adoption and fleet compliance verification

- Occupational Safety and Health Administration (OSHA)

- Enforces workplace safety standards and conducts inspections that can lead to citations if violations are found

Compliance becomes even more complex when operating across multiple states or regions with overlapping and conflicting requirements.

| Pro tip: Automate compliance tracking using electronic driver vehicle inspection report, HOS logs and emissions reports. Telematics platforms can help you stay ahead of audits with centralized documentation, automatic alerts and real-time compliance status. |

Complex data integration

Companies often use separate systems for different operational functions — from dispatch to inspections — creating data silos that prevent a unified view of fleet performance.

This fragmented approach can lead to missed opportunities for optimization, delayed reporting and poor decision-making.

| Pro tip: Adopt an open-platform telematics solution that integrates seamlessly with your maintenance, ERP and compliance systems. Centralizing data allows for more robust analytics, better cross-team collaboration and faster responses to issues. |

Geopolitical and economic instability

Fluctuating global oil prices impact capital spending, while geopolitical events — such as trade sanctions, regional conflicts or blockades of key shipping routes — require adaptive logistics and real-time fleet monitoring to ensure operational continuity.

Fleets must be prepared to pivot quickly while maintaining high safety and compliance standards.

| Pro tip: Build resiliency into your operations by leveraging real-time fleet visibility, route alternatives and geofencing. Having up-to-date intelligence on vehicle locations and geopolitical hotspots allows faster response to disruptions and reduces financial exposure. |

Labor shortages

Many fleets struggle to recruit and retain qualified drivers, technicians and equipment operators, especially in rural areas where demands are highest.

As experienced workers retire, organizations are turning to telematic methods and advanced diagnostics to bridge the skills gap and maintain high safety and productivity standards.

“An aging workforce and a shortage of skilled labor are driving a greater emphasis on automation and digitalization to improve operational efficiency.”

— Jenny Koschanow, Senior Segment Marketing Manager at Geotab

These technology investments help less experienced crews make data-driven decisions, automate routine compliance tasks and reduce the risk of human error in critical processes.

Over time, companies that proactively adopt digital tools and training programs are better positioned to mitigate the impact of labor constraints on fleet performance.

| Pro tip: Support onboarding and retention with user-friendly telematics that simplify troubleshooting and automate routine tasks. Use built-in fault code explanations and mobile workflows to reduce training time. |

Benefits of fleet management in the oil and gas industry

Oil and gas operations are high-risk, capital-intensive and geographically complex. A strong fleet strategy helps companies cut costs, increase uptime and strengthen safety while staying agile in a volatile market.

According to Koschanow, leading fleets are already gaining a competitive edge by using advanced telematics and asset tracking systems to operate more efficiently, respond faster to change and uncover new areas for savings.

Improved fleet safety

Fleet management tools help these organizations protect their workers, vehicles and high-value equipment, especially in rugged environments where risk levels are high.

By tracking driver behavior and implementing advanced safety measures, managers can reduce accidents and ensure compliance with HSE standards.

“Telematics can monitor driver behavior, track fatigue and provide in-vehicle coaching to reduce accidents and improve safety.”

— Jenny Koschanow, Senior Segment Marketing Manager at Geotab

These tools also help enforce fleet oil and gas safety standards by managing Hours of Service, monitoring seatbelt use and identifying risky driving patterns. In high-hazard industries like oil and gas, even small improvements in safety can prevent major incidents and reduce liability.

Reduced operating costs

Fuel, downtime, fleet refueling and maintenance represent a huge portion of operating costs for these fleets. These solutions help reduce unnecessary expenses through data and proactive monitoring.

By identifying inefficiencies and automating reporting, these tools help reduce fuel burn, extend equipment life and streamline compliance tasks, ultimately lowering total fleet costs.

Increased equipment uptime

Unplanned downtime can cost up to $200,000 an hour. That’s why leading fleets focus on predictive maintenance and real-time visibility to keep operations running.

“Leading oil and gas companies use predictive analytics and real-time data to forecast maintenance needs and reduce unnecessary wear, maximizing uptime.”

— Jenny Koschanow, Senior Segment Marketing Manager at Geotab

For example, telematics lets managers optimize service schedules using real engine data, catch issues early and track usage across remote job sites. These tools help them keep every vehicle and piece of equipment mission-ready.

Tips to use telematics for oil and gas asset and behavior tracking

Oil and gas companies rely on telematics and asset tracking to manage complex logistics and improve efficiency across large, often dispersed operations. These tools help reduce costs, increase visibility and enhance safety — especially in a high-risk industry where uptime and compliance are non-negotiable.

Below are the most common use cases and how fleets are seeing results:

Remote asset monitoring

In a sector where operations extend across remote and rugged locations, real-time tracking is critical. Telematics enables centralized visibility of assets, equipment and vehicles, even in isolated environments with limited oversight.

“Telematics provides real-time tracking and logistics coordination to improve supply chain efficiency and meet project timelines. It also enables remote monitoring, which is crucial for assets in isolated locations.”

— Jenny Koschanow, Senior Segment Marketing Manager at Geotab

This is especially useful for oil and gas asset tracking, where fleets include a mix of heavy-duty trucks, trailers, drill rigs and non-powered equipment. With the right platform, operators can:

- Prevent asset loss

- Ensure efficient routing

- Reduce downtime across sprawling job sites

Fuel management tools

Fuel is one of the largest variable costs for oil and gas fleets. These platforms help managers track consumption, reduce idle time and schedule maintenance to avoid fuel waste and extend equipment life.

“Companies use telematics to reduce idle time, schedule predictive maintenance and monitor fuel consumption, which lowers operational costs and prevents unplanned downtime,” says Koschanow.

This level of data-driven insight helps fleets improve overall fuel efficiency, uncover potential leaks or overuse and support fuel management system tools that align with sustainability and cost-reduction goals.

Compliance and regulatory reporting

Oil and gas fleets must meet strict HSE regulations, plus rules around emissions, HOS and driver inspections. Telematics platforms can automate much of this reporting to reduce manual work and avoid penalties.

“Telematics solutions are critical for ensuring compliance with strict safety and environmental regulations.”

— Jenny Koschanow, Senior Segment Marketing Manager at Geotab

This also includes driver behavior monitoring. Many platforms offer pre-trip and post-trip inspection workflows, customizable alerts and intuitive reporting dashboards designed to streamline roadside checks, maintain audit readiness and enhance oil and gas fleet safety.

Specialized equipment management

Specialized fleets include not only vehicles but also high-value, complex equipment like:

- Drill rigs

- Wireline trucks

- Generators

Telematics solutions allow operators to track the usage, location and performance of this specialized equipment, even in extreme environments.

Koschanow says that service providers like Schlumberger and Halliburton use telematics to manage this type of equipment, ensuring efficiency and safety on job sites.

How to digitize your oil and gas operations

For fleet managers just beginning to digitize their operations, the key is to focus on solving real-world challenges and finding practical ways to optimize their oil and gas fleet. Digital transformation doesn’t have to mean overhauling everything at once.

Instead, start small with scalable tools that deliver immediate results and lay the groundwork for long-term growth.

As Koschanow puts it, “Begin by addressing immediate challenges such as vehicle and asset tracking, fuel reduction, maintenance optimization and safety monitoring.”

Here’s how to get started:

1. Start with your biggest operational pain points

Don’t try to digitize everything at once. Focus on the areas causing the most inefficiencies or compliance risks, like idle time, equipment visibility, maintenance delays and driver safety.

“For a fleet manager beginning their digital transformation journey, the key is to start with foundational elements,” says Koschanow.

By narrowing your focus, you give your team time to learn the systems, adjust workflows and build confidence with the technology. Starting small also makes it easier to measure ROI and get buy-in from leadership and field teams, making future rollouts faster and more successful.

Once you solve those immediate issues, you can expand your tools and integrations to other parts of the operation, layering in more complexity as your team becomes more comfortable.

2. Choose scalable, flexible solutions

If you're a small or mid-sized operator, you need tools that can grow with you. Look for vendors that offer:

- Flexibility

- Fast onboarding

- Customer support tailored to your business size

“Smaller firms often value flexibility, speed and direct relationships with vendors over formal, complex procurement processes.”

— Jenny Koschanow, Senior Segment Marketing Manager at Geotab

Avoid platforms that lock you into long contracts or require large upfront investments before you see value.

3. Look for bundled and affordable options

Digitizing your fleet doesn’t have to be expensive. Many providers offer bundled solutions that include asset tracking for oil and gas, maintenance alerts and driver behavior tools in one package.

According to Koschanow, “Small enterprises, which have the lowest telematics adoption rates, often look for affordable and bundled solutions that address their foundational needs without a high initial investment.”

Combined platforms help you reduce vendor sprawl and give your team a single system to work from.

4. Make integration a priority

As your tech stack grows, integration becomes essential. Look for telematics platforms that can connect with key business systems like your ERP, accounting software, ELDs, fuel management tools and maintenance platforms.

Geotab’s platform supports these integrations and more. With Geotab, you can integrate AEMP 2.0 data from heavy equipment manufacturers like Caterpillar, John Deere and Komatsu.

This gives you a unified view of both on-road and off-road assets within a single system, helping avoid data silos, accelerate decision-making and improve visibility across your entire operation.

5. Understand the ROI of digital tools

Don't implement digital solutions just for the sake of it. Make sure every new tool solves a specific problem and delivers measurable value. Koschanow recommends focusing on these key features to boost your ROI:

- Real-time tracking

- Idle time monitoring

- Compliance tools

6. Prioritize cybersecurity and data protection

With more connected vehicles, remote assets and cloud-based tools, oil and gas fleets are increasingly exposed to cyber risks. Choosing secure telematics platforms isn’t just about IT; it’s about protecting critical infrastructure.

Look for vendors that follow industry best practices for data encryption, user authentication and compliance with standards like ISO 27001.

Make sure your telematics platform offers clear data governance policies and integrates well with your existing security frameworks.

What’s next for oil and gas fleet management?

The oil and gas industry is rapidly evolving — and so is the way fleets operate. As the energy sector moves toward cleaner fuel, more complex compliance requirements and tighter margins, digital tools will be essential for keeping operations effective.

“The industry will continue its shift toward digitalization,” says Koschanow. “That includes AI, remote monitoring and cloud platforms that enable smarter, data-driven decisions.”

These technologies don’t just collect data; they turn it into actionable insights. AI and advanced analytics help predict maintenance needs, optimize routes and flag compliance risks before they escalate. Remote monitoring extends visibility to even the most isolated assets, while cloud-based systems ensure data flows across departments, devices and sites in real time.

This connected approach gives oil and gas companies the agility they need to respond to sudden market changes, reduce downtime and future-proof their operations. Fleets that invest in digital innovation today are building the foundation for safer, leaner and more sustainable energy operations tomorrow.

Ready to digitize your operations? Geotab’s fleet management solutions for oil and gas help operators tackle these challenges head-on.

Subscribe to get industry tips and insights

Frequently Asked Questions

Fleet management for oil and gas is the process of tracking, maintaining and optimizing vehicles and equipment used in exploration, production and transport.

It involves using digital tools and telematics to improve safety, reduce operating costs, ensure regulatory compliance and maximize asset uptime across dispersed and rugged locations.

Companies use telematics to monitor vehicle performance, track assets in real time, optimize routes and improve fleet utilization across remote sites. Advanced solutions can also monitor fuel consumption, driver behavior and maintenance needs to help reduce costs and improve safety.

Oil and gas fleets use a combination of cellular, satellite and radio communication technologies to maintain connectivity in remote locations where traditional networks are unreliable.

Advanced telematics devices often have dual-mode communication capabilities, automatically switching between cellular and satellite signals to ensure continuous data transfer. This helps companies track assets, monitor safety and coordinate logistics even in areas without consistent coverage.

Telematics systems follow strict data encryption and access control protocols to protect sensitive operational information. Many providers also offer compliance with industry standards and customizable permissions to safeguard fleet data.

Start by identifying key operational pain points, then align stakeholders across safety, operations and IT. From there, prioritize a phased rollout, beginning with high-impact assets to prove value early.

These tools provide real-time visibility into third-party usage, helping ensure equipment is being used efficiently, safely and within contract terms. They also simplify reporting and billing across owned and rented assets.

The Geotab Team write about company news.

Table of Contents

Subscribe to get industry tips and insights

Related posts

Telematics trends for 2026: What is changing and how fleets can respond

January 30, 2026

6 minute read

Fleet GPS tracking systems cost: Full price breakdown and ways to boost ROI

January 30, 2026

6 minute read

Fleet operations: Key components, benefits and challenges

January 7, 2026

4 minute read

.jpg)

10 best fleet management software to boost performance and cut costs

December 22, 2025

8 minute read

The $4B Crisis: Video Intelligence as the Answer to Fleet Distraction

December 2, 2025

3 minute read