26 types of construction vehicles to add to your fleet + how to use them

Explore 26 types of construction vehicles, their uses and key features to optimize your fleet. Find the right heavy equipment for your projects.

By Geotab Team

Jul 21, 2025

Key Insights

- The most popular construction vehicles include excavators, dump trucks, loaders and cranes, which are essential for most job sites.

- Adding the right vehicles to your fleet improves efficiency, reduces labor costs and helps keep projects on schedule.

- Geotab helps you manage your fleet with real-time tracking, predictive maintenance, driver safety monitoring and fuel optimization tools.

In 2021, more than 1.2 million construction vehicles were sold around the world. Excavators made up the largest share, with over 462,700 units sold, and that number is expected to reach 518,700 by 2030.

The takeaway? Construction fleets are growing fast, and competition is, too. To stay ahead and avoid high downtime costs, you need to build a fleet that’s not just big, but smart. That means investing in the right mix of machines for your job sites, not just adding vehicles at random.

But with so many options available, it can be hard to know what’s truly essential. Explore 26 key names of construction vehicles, what each one does and how they can help your team work more efficiently and safely.

1. Articulated hauler

- Commonly used for: Moving heavy loads across rough or uneven terrain

- Key feature: Pivot joint between cab and trailer for easy maneuvering

- Vehicle business value: Cuts time and labor needed to haul materials, even on difficult job sites

An articulated hauler, also called an articulated dump truck (ADT), is designed to carry large loads across rough ground. Unlike rigid trucks, it has a flexible joint that lets the cab and trailer move separately. This makes it easier to steer around tight turns or hilly terrain.

If your team hauls dirt, rock or debris often, this is a smart vehicle to have. It’s especially useful for off-road construction, mining and large earthmoving jobs. You’ll save time on transport and reduce wear on other equipment.

2. Asphalt paver

- Commonly used for: Laying down roads, parking lots and paths

- Key feature: Smoothly spreads hot mix asphalt for even surfaces

- Vehicle business value: Delivers a higher-quality finish with fewer manual corrections

An asphalt paver lays hot asphalt on roads and other surfaces before it's compacted by a roller. It comes in two types: tracked pavers (better for rough ground) and wheeled pavers (faster and more mobile).

If your projects include road building or resurfacing, a paver is essential. It’s used often in municipal and commercial jobs where smooth pavement matters. Adding one helps your crew finish faster with fewer errors.

3. Backhoe loader

- Commonly used for: Digging, trenching, lifting and moving materials

- Key feature: Combines a front loader and backhoe on one machine

- Vehicle business value: Saves space and money by doing the job of two machines

A backhoe loader is one of the most versatile tools you can add to your fleet. It has a loader bucket in front for moving materials and a backhoe arm in the rear for digging. You can also attach tools like hammers or augers to handle more jobs.

Backhoes are used on almost every type of site — from home builds to roadwork. Because it handles multiple tasks, it keeps your fleet lean and efficient, especially for smaller crews.

4. Boom lift

- Commonly used for: Reaching high places for repairs, installations or inspections

- Key feature: Extendable arm for vertical and horizontal access

- Vehicle business value: Improves safety and efficiency for jobs at height

A boom lift is an aerial work platform with a long, extendable arm. It lifts workers and tools to hard-to-reach spots. There are two main types: telescopic (for straight, long reaches) and articulating (for working around obstacles).

It’s a go-to vehicle for tasks like installing signs, painting tall structures or fixing power lines. If your team often works above ground level, a boom lift cuts setup time and lowers the risk of falls.

5. Bulldozer

- Commonly used for: Pushing earth, clearing land and grading

- Key feature: Heavy-duty front blade for moving materials

- Vehicle business value: Speeds up site prep and reduces labor costs

A bulldozer is a powerful machine with a wide, flat blade in front. It pushes soil, debris and other materials out of the way. Some models also have a ripper attachment at the back for breaking up tough ground.

Dozers are common on road, mining and building sites, especially in the early stages of a project. They do quick clearing and leveling work, which helps your team stay on schedule.

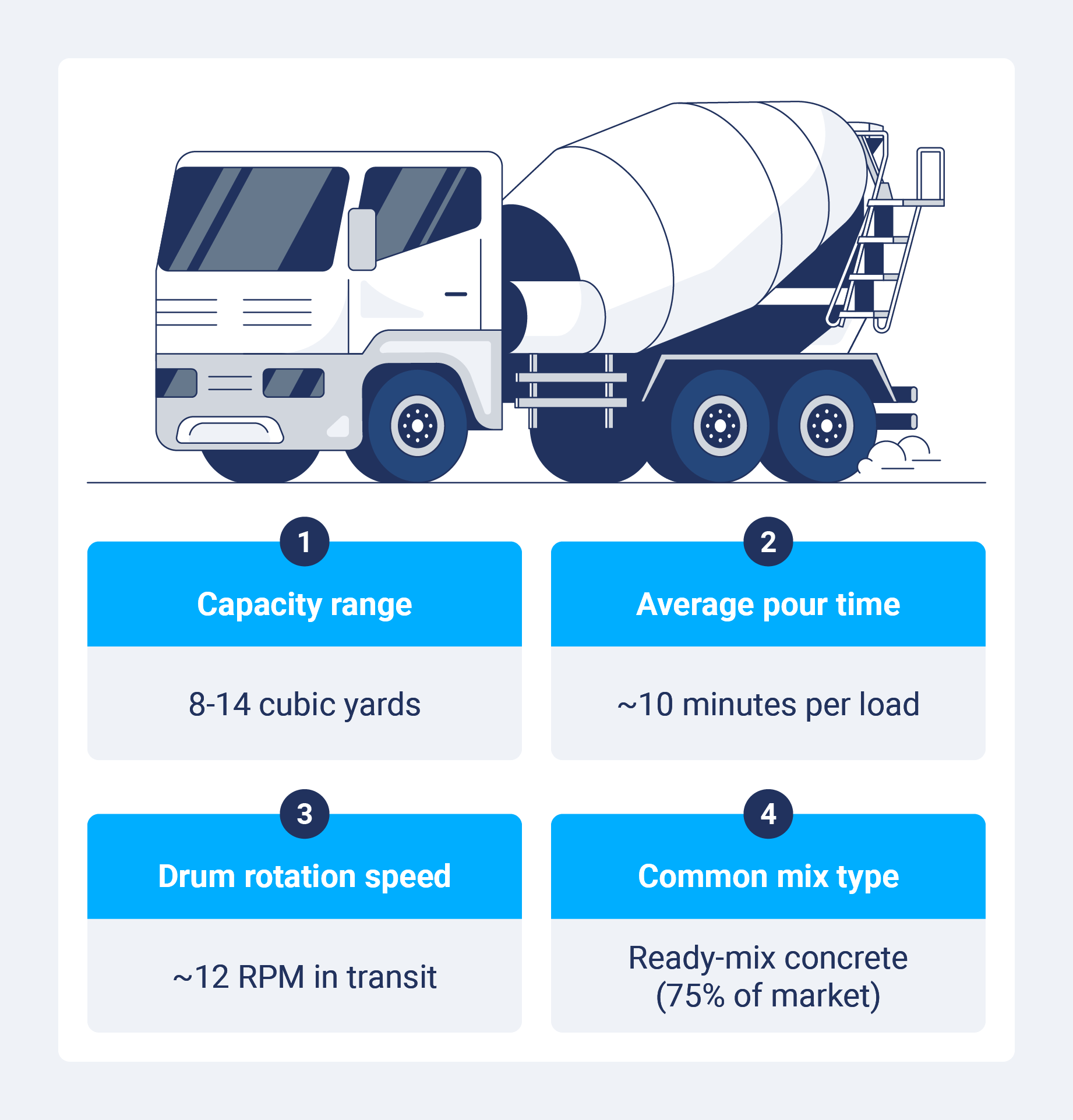

6. Cement mixer

- Commonly used for: Mixing and transporting cement to job sites

- Key feature: Rotating drum keeps cement from hardening during transit

- Vehicle business value: Reduces material waste and speeds up concrete work

A cement mixer truck keeps cement moving and ready to pour as it travels from the plant to the job site. The spinning drum prevents the mix from setting too early, which saves your crew from delays and extra cleanup.

This is a must-have if your projects involve concrete foundations, sidewalks or slabs. It keeps your timeline on track and avoids the cost of ruined batches.

7. Cold planer

- Commonly used for: Removing asphalt or concrete from road surfaces

- Key feature: Rotating drum with sharp cutters for grinding pavement

- Vehicle business value: Prepares surfaces quickly for new paving, reducing downtime

A cold planer, also known as a milling machine, grinds and removes old pavement so crews can lay fresh asphalt or concrete. It’s often used in road repair and resurfacing jobs.

Cold planers are ideal for municipalities, road contractors or anyone handling repaving projects. They make surface prep faster and more precise, which means fewer delays and a smoother final result.

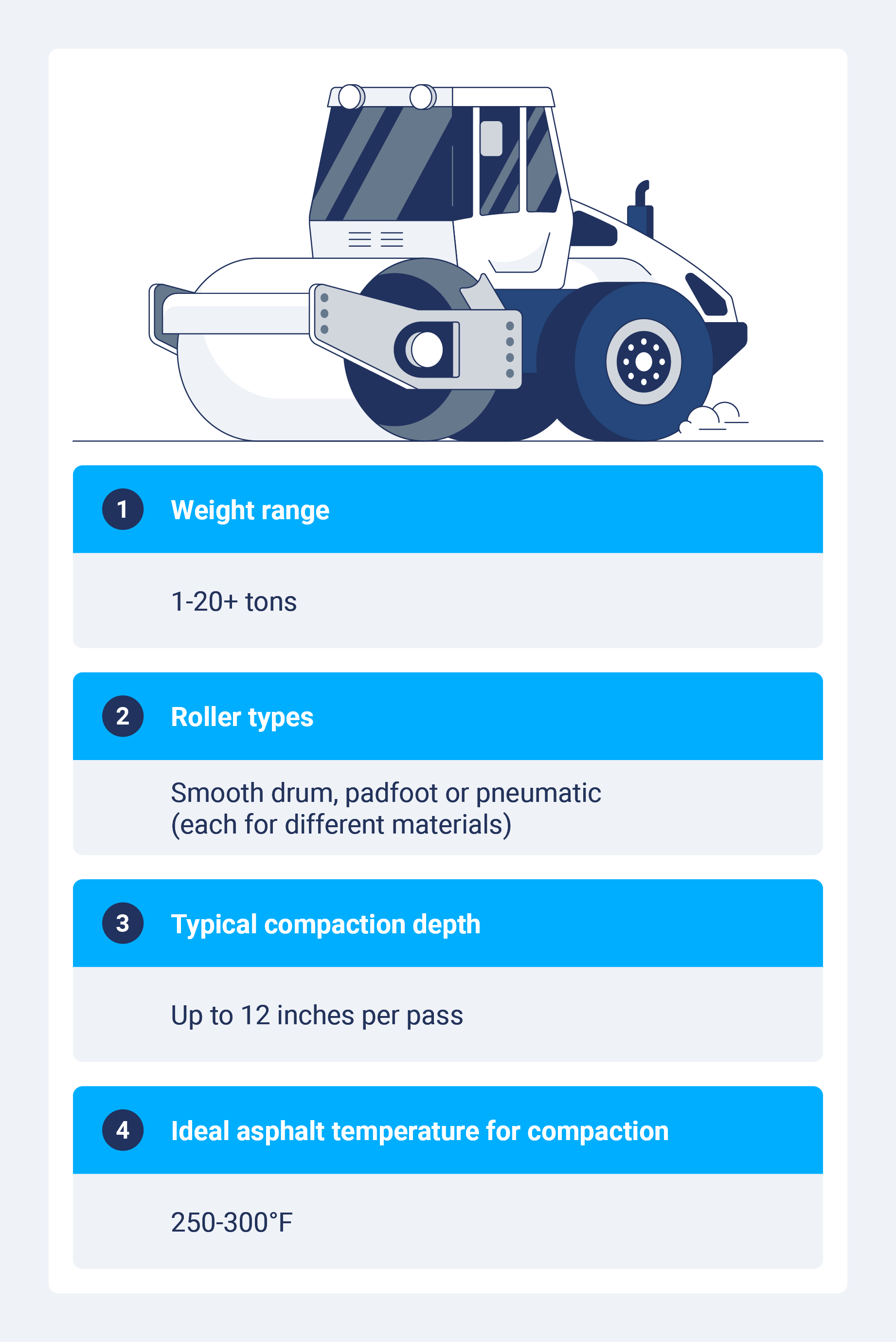

8. Compactor

- Commonly used for: Compressing soil, gravel or asphalt

- Key feature: Heavy roller or vibrating plate for even surface compression

- Vehicle business value: Strengthens surfaces and prevents future repairs

A compactor helps create solid, stable surfaces by pressing down loose material. There are different types: vibratory rollers for asphalt and plate compactors for soil or sand.

This machine is used frequently in road construction, foundations and landscaping. Compacting layers properly reduces settling and cracks later on, saving you money on rework.

9. Concrete mixer

- Commonly used for: Mixing concrete for small to mid-sized jobs

- Key feature: On-site mixing for better control of batch size and timing

- Vehicle business value: Cuts waste and labor for jobs that don’t need a full truckload

A concrete mixer is a smaller, often portable machine used to mix concrete at the construction site. It’s perfect for smaller batches where a full cement mixer truck would be overkill.

If your jobs include patios, sidewalks or post footings, this is a smart addition. It lets you mix as you go, keeping materials fresh and reducing wait times.

10. Crane

- Commonly used for: Lifting and placing heavy materials at height

- Key feature: Extendable arm and hook system for vertical lifting

- Vehicle business value: Cuts down on manual lifting and speeds up builds

A crane is essential for heavy lifting on construction sites, such as placing beams, moving steel or installing HVAC units. Cranes come in many types, including mobile, tower and truck-mounted, and they can be fitted with hooks, clamps or lifting slings.

If your projects include tall structures or oversized materials, a crane can help your team do the job faster and more safely. It also reduces the need for extra labor or multiple machines.

11. Dump truck

- Commonly used for: Hauling and unloading loose materials like gravel, sand or debris

- Key feature: Tilting bed for quick and controlled unloading

- Vehicle business value: Speeds up cleanup and delivery jobs, reducing turnaround time

A dump truck is one of the most common and essential construction vehicles. Its hydraulic bed lifts to unload materials quickly and safely. These trucks come in various sizes, from light-duty to off-road models for bigger jobs.

They’re used daily on most sites to move materials in and out. Whether you're hauling gravel for roadwork or clearing debris after a demolition, dump trucks keep things moving and help crews stay on schedule.

12. Excavator

- Commonly used for: Digging, demolition and heavy lifting

- Key feature: Long boom arm with a bucket or other attachment

- Vehicle business value: Handles big tasks with fewer machines and less manual labor

An excavator is a powerful machine used for digging deep holes, trenches and foundations. It can also lift heavy materials and break through tough surfaces. The boom and bucket can be swapped for hammers, grapples or augers for even more jobs.

Excavators are a workhorse on any medium to large site. They’re used often and can do the work of several smaller machines, making them a valuable piece of your fleet.

13. Feller buncher

- Commonly used for: Cutting and gathering trees in forestry or land-clearing projects

- Key feature: Cutting head that grabs, cuts and stacks trees in one motion

- Vehicle business value: Boosts productivity in site prep and reduces manual tree removal

A feller buncher is a specialty machine that cuts down trees quickly and safely. It holds the tree in place while cutting, then stacks it neatly for removal. This makes it far faster and safer than chainsaws or other manual tools.

If your projects involve land clearing or are in wooded areas, this is a smart addition to your fleet of different construction vehicles. It’s used often in early site development to prep the land for new builds or roads.

14. Forklift

- Commonly used for: Lifting and moving heavy materials across short distances

- Key feature: Forked front arms that raise, lower and carry loads

- Vehicle business value: Makes loading, unloading and staging materials faster and safer

A forklift is one of the most popular small construction vehicles, perfect for indoor or outdoor material handling. It’s commonly used to move pallets, equipment or supplies around warehouses and job sites.

Forklifts are essential for loading deliveries, organizing storage and helping crews lift materials without strain. They’re a low-cost, high-value asset that improves workflows across many project types.

15. Forwarder

- Commonly used for: Transporting logs from the cutting site to the loading area

- Key feature: Built-in loading crane and enclosed log bed

- Vehicle business value: Cuts down time and labor in forestry and clearing work

A forwarder is used mainly in logging and land clearing. It carries cut logs from the feller buncher or harvester to a central location, often over rough terrain. Its onboard crane makes it easy to load and unload quickly.

If your construction work includes clearing large wooded areas, a forwarder keeps the job moving. It reduces the number of machines and workers needed on-site, which helps lower your operating costs.

16. Front-end loader

- Commonly used for: Moving heavy materials like soil, gravel or debris

- Key feature: Large bucket on the front for scooping and lifting

- Vehicle business value: Boosts productivity in material handling and reduces manual labor

A front-end loader is a versatile machine with a large bucket at the front. It’s used for scooping up and moving materials like dirt, rocks or sand from one location to another. It’s often used for digging, lifting and loading trucks.

Front-end loaders are used frequently on construction sites for a wide range of tasks. Adding one to your fleet means faster material handling and less time spent on manual labor.

17. Grader

- Commonly used for: Leveling and smoothing surfaces

- Key feature: Long adjustable blade for precise grading

- Vehicle business value: Ensures smooth, even surfaces for paving, reducing rework

A grader, or road grader, is used to level and smooth large areas of earth. It has a long, adjustable blade that can be set to different angles to create a perfectly flat surface, often for roads or foundations.

Graders are used frequently in road construction and earthmoving projects. They save time and improve the quality of the surface, making your projects more efficient and reducing the need for costly fixes later.

18. Manlift

- Commonly used for: Lifting workers to high places safely

- Key feature: Adjustable platform that can extend vertically and horizontally

- Vehicle business value: Increases worker safety and access to elevated areas, reducing fall risks

A manlift is an aerial platform used to lift workers to higher elevations. It comes in different types, including scissor lifts for vertical movement and boom lifts for both vertical and horizontal reach.

Manlifts are essential for jobs involving maintenance, installation or repairs at height. They improve worker safety, speed up tasks and reduce the need for scaffolding or ladders, making them an efficient choice for projects that require access to tall areas.

19. Paver

- Commonly used for: Laying asphalt or concrete on roads and surfaces

- Key feature: Spreads and levels material evenly for a smooth finish

- Vehicle business value: Reduces labor and time for paving projects, delivering a high-quality finish

A paver is used to lay asphalt or concrete, ensuring a smooth, even surface for roads, driveways and parking lots. It spreads the material evenly and at the right thickness, ensuring durability and a quality finish.

Pavers are frequently used in road construction and resurfacing. If your projects include any paving work, having a paver in your fleet helps speed up the process and guarantees a smooth, long-lasting result.

20. Road roller

- Commonly used for: Compacting asphalt or soil

- Key feature: Heavy drum that flattens and smooths surfaces

- Vehicle business value: Enhances surface durability and smoothness, reducing the need for repairs

A road roller is used to compact asphalt, soil or gravel, making the surface stable and smooth. The heavy drum presses down material to prevent shifting or uneven settling.

Road rollers are commonly used in road construction, landscaping and any job requiring surface preparation. Adding one to your fleet will help ensure smooth, durable surfaces that can withstand heavy traffic or weather conditions.

21. Roller

- Commonly used for: Compacting and smoothing surfaces like asphalt and soil

- Key feature: Heavy cylindrical drum for even pressure distribution

- Vehicle business value: Improves surface durability and reduces repair costs down the line

A roller is used to compact materials like soil, gravel or asphalt. The heavy drum presses down on the material, ensuring it’s even and stable. This is crucial for creating surfaces that won’t settle or crack over time.

Rollers are used frequently in road construction, parking lot preparation and landscaping. Having one in your fleet speeds up work and ensures smoother, more durable surfaces, cutting down on future maintenance.

22. Scissor lift

- Commonly used for: Lifting workers to high places for maintenance or installation

- Key feature: Platform that moves vertically in a scissor-like motion

- Vehicle business value: Increases worker productivity and safety at height

A scissor lift is a vertical lift platform that moves straight up and down. It’s used to lift workers to hard-to-reach areas, often in construction, warehouse or maintenance jobs. There are electric and rough terrain models, depending on the site conditions.

Scissor lifts are great for projects like ceiling installations, electrical work or general site maintenance. Adding one to your fleet ensures safer work at height and reduces the time spent setting up ladders or scaffolding.

23. Scraper

- Commonly used for: Moving and leveling large amounts of earth

- Key feature: Large, motorized scoop for loading, carrying and dumping soil

- Vehicle business value: Speeds up earthmoving tasks and increases site efficiency

A scraper is a machine used to collect and transport large quantities of dirt or gravel from one location to another. It has a scoop that can be lowered to collect material and then raised for transport, making it ideal for grading and leveling large sites.

Scrapers are often used in major earthmoving or road construction projects. By adding one to your fleet, you can increase efficiency in moving materials and reduce the need for manual labor.

24. Skid steer loader

- Commonly used for: Excavating, lifting and digging in tight spaces

- Key feature: Small, maneuverable size with a variety of attachments

- Vehicle business value: Boosts flexibility and versatility in small to medium-sized jobs

A skid steer loader is a compact machine with a small footprint, making it perfect for working in tight spaces. It’s extremely versatile, with attachments like buckets, forks and sweepers that make it useful for a variety of tasks, from digging to loading.

Skid steers are frequently used in landscaping, construction and material handling jobs. Adding one to your fleet means you can tackle a wide range of tasks without needing multiple machines.

25. Telehandler

- Commonly used for: Lifting and placing heavy loads at height or over obstacles

- Key feature: Extendable boom with various attachment options

- Vehicle business value: Increases lifting reach and versatility, reducing the need for multiple machines

A telehandler is a combination of a forklift and a crane, with a long, extendable boom that allows it to reach high areas or place heavy loads in hard-to-reach places. Common attachments include forks, a bucket and a lifting hook.

Telehandlers are used frequently in construction and agriculture, especially in sites where lifting over obstacles or at heights is required. Adding one to your fleet increases your operational range and reduces the need for multiple machines.

26. Trencher

- Commonly used for: Digging narrow trenches for utilities, pipelines or cables

- Key feature: Specialized digging chain for precise trenching

- Vehicle business value: Speeds up trenching work and reduces manual labor

A trencher is a machine designed to dig narrow, precise trenches for placing pipes, cables or other utilities. The digging chain can vary in size and depth, depending on the needs of the project.

Trenchers are used frequently in utility installation, irrigation and foundation work. Having one in your fleet makes trenching faster and more efficient, cutting down on manual labor and reducing project timelines.

Manage different types of construction vehicles with Geotab

When expanding your construction fleet, adding the right vehicles for your specific needs is essential. But choosing the right equipment isn’t enough — you need to manage it effectively, too.

Proper fleet management ensures your vehicles run at their best. It involves monitoring usage, maintaining regular service schedules and tracking driver performance.

Geotab's fleet management software helps manage your construction vehicles by offering:

- Telematics data: Get real-time insights into vehicle location, performance and usage.

- Predictive maintenance: Receive alerts for upcoming maintenance needs to prevent breakdowns.

- Driver safety monitoring: Keep track of driver behavior and ensure safer, more efficient driving.

- Dash cams: Enhance safety with in-vehicle cameras and asset trackers for accident and event recording.

- Fleet efficiency: Optimize fuel use, reduce idling and extend vehicle life.

Book a free demo today to learn how we can keep your construction vehicles running at peak performance, saving you time and money.

Subscribe to get industry tips and insights

Frequently Asked Questions

The most commonly used construction vehicles include:

- Dump trucks

- Excavators

- Bulldozers

- Front-end loaders

- Skid steer loaders

These machines handle a variety of tasks, like moving materials, digging and leveling, making them essential for most construction projects.

To manage your construction trucks effectively, you’ll need a fleet management system that includes GPS tracking, maintenance scheduling and driver monitoring. This helps you keep track of vehicle locations, ensure timely maintenance and improve overall fleet efficiency.

Not necessarily. The types of vehicles you need depend on the specific jobs you handle.

- For smaller projects, a few versatile machines like skid steer loaders or excavators may suffice.

- For larger, specialized projects, adding more specific vehicles like cranes or pavers might be necessary.

The Geotab Team write about company news.

Table of Contents

- 1. Articulated hauler

- 2. Asphalt paver

- 3. Backhoe loader

- 4. Boom lift

- 5. Bulldozer

- 6. Cement mixer

- 7. Cold planer

- 8. Compactor

- 9. Concrete mixer

- 10. Crane

- 11. Dump truck

- 12. Excavator

- 13. Feller buncher

- 14. Forklift

- 15. Forwarder

- 16. Front-end loader

- 17. Grader

- 18. Manlift

- 19. Paver

- 20. Road roller

- 21. Roller

- 22. Scissor lift

- 23. Scraper

- 24. Skid steer loader

- 25. Telehandler

- 26. Trencher

- Manage different types of construction vehicles with Geotab

Subscribe to get industry tips and insights

Related posts

Telematics trends for 2026: What is changing and how fleets can respond

January 30, 2026

6 minute read

Fleet GPS tracking systems cost: Full price breakdown and ways to boost ROI

January 30, 2026

6 minute read

Fleet operations: Key components, benefits and challenges

January 7, 2026

4 minute read

.jpg)

10 best fleet management software to boost performance and cut costs

December 22, 2025

8 minute read

The $4B Crisis: Video Intelligence as the Answer to Fleet Distraction

December 2, 2025

3 minute read