What is fleet lifecycle management? Guide to extend your vehicle’s life

Get the most out of every vehicle in your fleet by mastering fleet lifecycle management and learn how Geotab can help along the way.

By Geotab Team

Jul 29, 2025

Key Insights

- Fleet lifecycle management is the process of tracking a vehicle from purchase to retirement to maximize performance and value.

- It helps lower costs, reduce downtime, extend vehicle life and improve overall fleet efficiency.

- Geotab supports this process with tools like maintenance reminders, diagnostics and telematics for smarter decision-making.

With inflation, driver shortages and tighter delivery schedules, many fleets are being pushed to do more with fewer resources. According to our trucking industry statistics, trucking operating costs hit a record high of $2.27 per mile in 2024, up 0.8% from the previous year.

It’s no surprise that maintenance and vehicle replacement costs are among the top challenges for fleet managers today. That’s why fleet lifecycle management matters. Tracking each stage of a vehicle’s life helps cut down on breakdowns, reduce downtime and get the most value out of every truck in your fleet.

Learn more about fleet lifecycle management, how it works and practical tips to extend your vehicle’s life and improve your bottom line.

What is fleet lifecycle management?

Fleet lifecycle management is the process of tracking and managing every stage of your vehicle’s life, from the day you purchase it to the day it retires. This helps you make smarter decisions about when to buy, maintain or replace a vehicle.

This approach focuses on vehicle lifecycle planning to reduce unnecessary expenses, limit downtime and extend vehicle life. With strong fleet lifecycle cost management, you’re not just reacting to problems; you’re staying ahead of them with a clear strategy.

A good fleet lifecycle management plan usually includes:

- Choosing the right vehicles for your operations

- Setting a clear vehicle maintenance policy

- Tracking usage, mileage and repair history

- Knowing when it’s more cost-effective to replace than repair

- Budgeting for lifecycle costs, not just purchase price

- Using telematics and data to guide decisions

- Planning for resale or disposal at the end of the vehicle lifecycle

By managing the full lifecycle of each vehicle, you can stretch your investment further and keep your fleet running at its best.

Why maintenance management matters

When it comes to fleet maintenance, timing is everything. Small, routine services cost far less than major repairs — or worse, vehicle replacements.

For example, an oil change for a medium-duty diesel truck might cost around $120. But skip it too often, and you could face engine failure, with repairs running $5,000 or more. The same goes for tire rotations: Spend $50 to $75 now, or risk blowouts and $800+ in replacement costs later.

That’s why vehicle lifecycle management should always include a strong maintenance plan. It helps you stay ahead of costly problems and avoid downtime.

Here are the top benefits of effective maintenance management:

- Lower repair costs by catching issues early

- Longer vehicle lifespan through regular care

- Less unplanned downtime, keeping trucks on the road

- Better fuel efficiency with well-maintained engines and tires

- Higher resale value thanks to a clean maintenance record

- More predictable budgets with fewer surprise expenses

- Improved driver safety by preventing breakdowns or accidents

A little maintenance goes a long way, especially when it’s part of your bigger fleet lifecycle strategy.

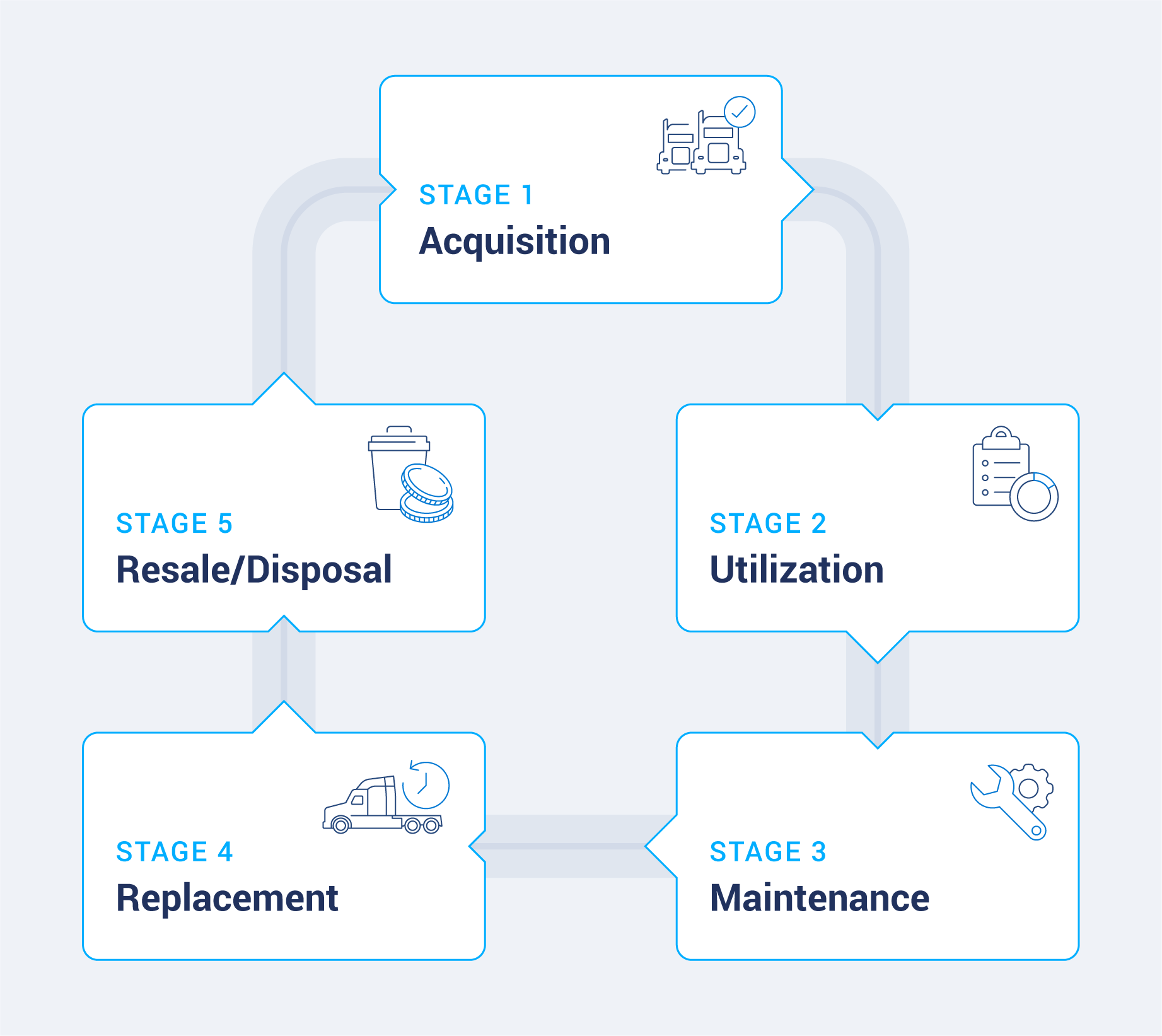

Key components of fleet lifecycle management

Fleet lifecycle management isn’t just about keeping trucks on the road. It’s also about knowing the right time to invest, maintain and replace.

Each stage of a vehicle’s life needs attention, from the moment you choose it to the moment it leaves your fleet. By focusing on the full picture, you can control costs, reduce risk and keep operations running smoothly.

The most important parts of fleet replacement and lifecycle management include:

- Vehicle acquisition: Selecting the right make, model and specs based on your fleet’s needs

- Maintenance planning: Following a consistent predictive maintenance schedule to avoid costly breakdowns

- Utilization tracking: Monitoring mileage, fuel use and performance over time

- Replacement timing: Replacing vehicles at the ideal point, like before repair costs spike or reliability drops

- Disposal or resale: Offloading vehicles in a way that brings in the most value

When these components work together, you get a more efficient, cost-effective fleet that lasts longer and performs better.

Fleet lifecycle costs

Fleet vehicles come with ongoing costs that add up quickly over time. These include:

- Ownership costs like purchase price, financing and depreciation

- Operating costs like fuel, maintenance, insurance and repairs

Underutilized vehicles can cost fleets thousands per year in wasted expenses. Without a strong fleet vehicle cost management strategy, you might overspend on vehicles that are either too old, poorly maintained or not used enough.

Understanding your fleet asset utilization and full fleet lifecycle cost helps you make smarter decisions about when to replace, maintain or retire a vehicle so you can get the most out of every mile.

How to lower lifecycle costs

Managing your transportation lifecycle costs is all about planning ahead and making each dollar count. Here’s how to lower your overall fleet lifecycle costs:

- Right-size your fleet: Make sure you’re not keeping more vehicles than you actually need.

- Follow a preventive maintenance schedule: Fixing issues early reduces expensive breakdowns later.

- Monitor utilization: Identify underused vehicles and either repurpose or remove them.

- Use telematics data: Track fuel efficiency, idle time and driver behavior to find cost-saving opportunities.

- Plan for timely replacements: Replace vehicles before repair costs outweigh their value.

- Train drivers: Safer, more efficient driving can lower fuel use and reduce wear and tear.

A proactive approach to transportation lifecycle management can lead to fewer surprises, better performance and long-term savings.

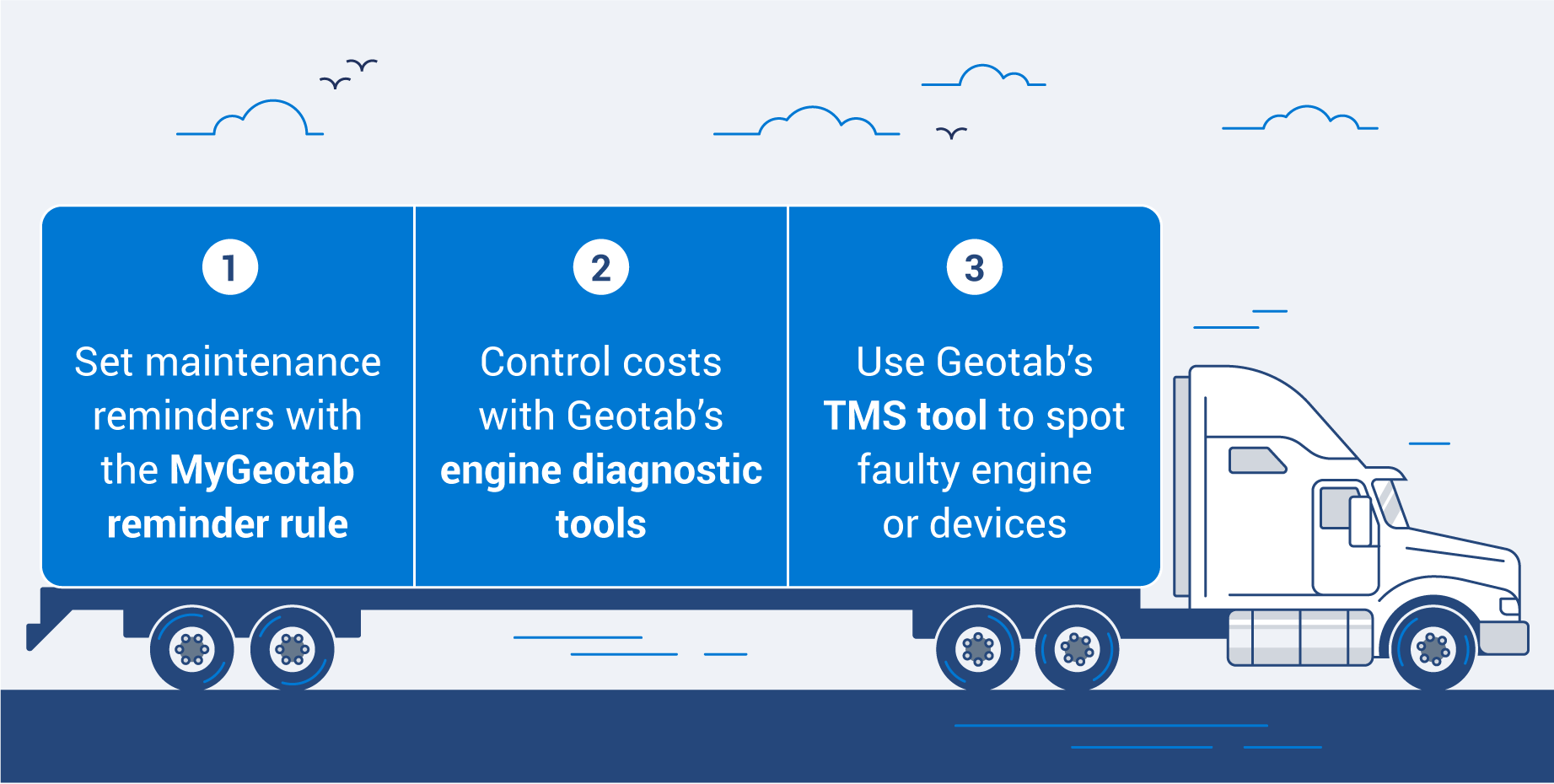

How Geotab helps with fleet lifecycle management

Geotab makes fleet lifecycle management easier by giving you the tools to monitor, maintain and optimize your vehicles using real-time data. From maintenance reminders to engine diagnostics, Geotab’s IoT fleet management system helps you get ahead of problems, extend vehicle life and reduce costs. Here’s what you can do with Geotab.

Set maintenance reminders

Staying on top of vehicle maintenance is easier with Geotab’s reminder rule in MyGeotab. This free, customizable tool lets you create maintenance reminders based on time, mileage or engine hours — whichever makes sense for your fleet.

You don’t need a full vehicle history to get started. Here’s what you need to do:

- Just input the most recent maintenance events.

- Geotab tracks and resets the counters with every service entry.

- You can also use this tool for license renewals, safety inspections, emissions checks or annual driver physicals.

To streamline it further, download the free Dynamic Vehicle Maintenance Reminder Report, which helps automate reminders across your fleet.

Watch how to schedule maintenance reminders in MyGeotab

Save money with engine diagnostics

In tough times, cost control matters more than ever. Geotab’s diagnostics tools help you spot problems early so you can act before they turn into expensive repairs.

Here are two helpful maintenance rules you can enable in MyGeotab:

- Engine Light On: This identifies when a vehicle’s check engine light is active, so you can act before minor issues become major. On average, check engine lights stay on for 90 days, wasting both fuel and performance.

- Battery Drain: This alerts you when battery voltage drops below 9, helping prevent dead batteries, missed jobs and costly tow calls.

These features give you more control — and fewer surprises — when it comes to maintenance and repairs.

Get key diagnostic reports

With Geotab’s transportation management system (TMS) tools, you can get daily or weekly reports that break down the health of your fleet. These reports help you prioritize maintenance, reduce downtime and keep your vehicles running efficiently.

The reports you get include:

- Engine Fault Report: This report pulls data from your vehicle’s engine control module (ECM) and highlights fault codes and their sources. Share this info with mechanics or your fleet management team so they can act fast.

- Telematics Fault Detection Report: This shows which devices are having issues, such as low battery voltage or warning lights. It’s a great way to stay ahead of small problems before they snowball into major repairs.

Watch how to view engine faults in MyGeotab

Simplify fleet lifecycle management with Geotab

Managing a fleet doesn’t have to be overwhelming. With the right tools in place, you can reduce fleet management costs, avoid downtime and get more life out of every vehicle. That’s the power of smart fleet lifecycle management.

Geotab’s fleet maintenance solutions give you real-time insights, automatic reminders and powerful diagnostic tools in one easy-to-use platform. Whether you’re tracking routine maintenance or planning for vehicle replacement, Geotab helps you stay one step ahead.

Subscribe to get industry tips and insights

Frequently Asked Questions

The four major components of a fleet management system are:

- Vehicle acquisition

- Maintenance management

- Fuel management

- Fleet replacement

These areas help ensure vehicles are operating efficiently, costs are controlled and replacements happen at the right time. Optimizing each component is key to effective fleet lifecycle management.

Key performance indicators (KPIs) for fleet management include vehicle uptime, fuel efficiency, maintenance costs and driver behavior. These KPIs help you track performance, reduce costs and improve overall fleet efficiency.

Maintenance needs are tracked through vehicle telematics, which monitor metrics like mileage, engine hours and maintenance history. You can also set alerts and reminders for routine services like oil changes, tire rotations and inspections.

Telematics play a crucial role in fleet lifecycle management by providing real-time data on vehicle performance. This data helps track maintenance needs, identify issues early and make informed decisions about vehicle replacements, ultimately optimizing the lifecycle of each vehicle.

The Geotab Team write about company news.

Table of Contents

Subscribe to get industry tips and insights

Related posts

Building resilient school bus operations through four student transportation trends

February 24, 2026

6 minute read

How to stop wasting mechanic hours on ‘ghost codes’ and low-priority repairs

February 2, 2026

2 minute read

.jpg)

Go beyond reactive truck maintenance with predictive solutions that drive profits

December 8, 2025

3 minute read

Protecting Our Most Precious Cargo: How Telematics is Powering a Safer Ride to School

October 23, 2025

2 minute read

The top five benefits of intelligent police fleet maintenance

August 21, 2025

5 minute read