What is fleet maintenance? Key benefits and checklist for managers

Fleet maintenance is key to keeping your vehicles on the road, your drivers safe and your customers happy, but without the right approach, maintaining multiple vehicles can become costly and overwhelming.

By Ben Schwartz

Dec 16, 2025

Key Insights

- Fleet maintenance uses systematic inspections, repairs and preventative care to keep commercial vehicles operating safely and efficiently.

- Proactive maintenance reduces operating costs and prevents costly emergency repairs.

- Modern telematics and fleet management software automate maintenance scheduling, providing real-time diagnostics and predictive insights.

Between juggling maintenance schedules, meeting compliance deadlines and keeping drivers on the road, fleet managers face constant pressure to do more with less. A single missed oil change could cascade into a costly engine replacement, while one failed inspection could take a vehicle out of commission for days. This is why fleet maintenance is so essential.

Creating a maintenance program can help maximize uptime and ensure the safety and efficiency of your operations, especially when implemented alongside fleet maintenance software.

Let’s dig into the elements of a good fleet maintenance process, including monthly, quarterly, biannual and annual mechanical checklists to keep on hand.

What is fleet maintenance?

So, what exactly is fleet maintenance? Automotive fleet maintenance is the practice of upkeeping fleet vehicles with regular mechanical checks and preventative care. A fleet maintenance manager schedules and oversees vehicle maintenance to help reduce downtime caused by surprise repairs.

A fleet maintenance program involves several key components:

- Scheduling recurring maintenance events: Maintenance events vary from a basic oil change to a full DOT safety inspection. The most common maintenance events are oil changes and air filter replacements.

- Overseeing routine inspections of fleet vehicles: This includes regular check-ups, tire rotations, brake inspections and fluid level checks.

- Deploying driver training: Drivers must understand vehicle maintenance needs, so offering training and resources is key to a successful program.

- Utilizing fleet maintenance tools and reminders: Receiving early maintenance reminders can help you efficiently schedule necessary vehicle downtime to perform maintenance events and vehicle repairs.

Importance of fleet maintenance

The importance of fleet maintenance should not be underestimated. Neglecting upkeep often creates a domino effect of problems that can hurt your operations and drain your budget.

The math for fleet vehicle maintenance is simple. A $50 oil change can save you from a $40,000 engine replacement. In other words, the cost of ignoring maintenance is often far more than the cost of paying for the mechanic, an important factor to consider when prioritizing ROI vs. COI.

Beyond cost savings, proper maintenance protects your drivers — and your customers. Well maintained vehicles are safer. They don’t leave your drivers stranded on dangerous roadways. And they don’t leave disgruntled customers with late orders.

The best way to stay on top of maintenance schedules is with fleet maintenance software.

These platforms automate vehicle upkeep by tracking maintenance history and vehicle usage data, often through telematics. They help fleet managers automate preventive maintenance scheduling, manage work orders and inventory, reduce operating costs, ensure regulatory compliance and maximize vehicle uptime, so you can meet customer commitments.

Benefits of fleet maintenance management

Using a structured fleet maintenance and repair approach will invariably pay off for your fleet in uptime and dollars saved. Take a look at how a proactive maintenance strategy can turn your fleet from costly to competitive.

Improves inspection outcomes

Regular inspections are the foundation of a well maintained fleet. By catching problems early with preventative maintenance inspections, you can address minor issues before they lead to major safety hazards and delays. A well managed program also ensures you meet Driver Vehicle Inspection Report (DVIR) compliance requirements.

Reduces operating and repair costs

Proactive maintenance is significantly cheaper than reactive repairs. Regularly checking oil levels can be a hassle, but it can prevent the need for a full engine replacement down the road. Plus, well maintained vehicles operate more efficiently, which helps lower fuel costs.

Aids in environmental, social and governance (ESG) goals

As we mentioned above, well maintained vehicles operate more efficiently, burning less fuel and producing fewer emissions. Reducing emissions benefits everyone. Whether you manage an EV fleet or not, switching to cleaner energy sources contributes to cost savings and a healthier planet.

Increases vehicle longevity

The better maintained your vehicles are, the less wear and tear they’ll experience and the longer they’ll run. When oil and filter changes and inspections are performed regularly, vehicles are less likely to run into serious issues down the road — aiding in a longer vehicle lifecycle.

Eliminates unnecessary downtime

Healthier vehicles lead to greater productivity. Vehicle downtime directly affects a vehicle’s ability to generate revenue. Eliminating unnecessary downtime will help your company maximize the revenue stemming from your fleet.

Improves driver safety

Staying on top of repairs doesn’t just save you money — it also keeps drivers and others safer on the road. Even something as simple as faulty wiper blades can lead to a collision. A robust fleet safety program is essential for protecting drivers, vehicles and your company’s reputation.

Supports regulatory compliance

The trucking industry has strict regulations for semi-truck maintenance and vehicle safety. Federal and state agencies require specific inspection schedules, maintenance standards and record-keeping requirements. Regular upkeep can help you avoid violations that result in fines, out-of-service orders and increased regulatory scrutiny.

Boosts fuel efficiency

Fuel represents 60% of a total fleet budget. That means even small increases in fuel efficiency can get you massive savings — and to get those small increases, you just have to stay up-to-date on your maintenance. That means regular tune-ups, clean air filters, proper tire inflation and quality oil.

Key maintenance challenges of fleet management

It’s clear that a fleet maintenance program offers a range of benefits, but there are a few considerations to weigh. Namely, that initial implementation can be challenging without the right tools.

- Scheduling and planning: It is difficult to keep track of multiple company vehicle maintenance schedules. Balancing routine inspections with unexpected repairs and aligning maintenance with driver availability can lead to scheduling conflicts and operational disruptions.

- Managing costs: Striking a balance between maintenance and operational expenses is a constant challenge. While investing in regular inspections can reduce costly breakdowns, justifying these upfront fleet costs can be difficult.

- Tracking maintenance history: A comprehensive maintenance history is essential for identifying trends, predicting future needs and ensuring compliance. And while maintaining accurate and accessible records for each vehicle is crucial for informed decision-making, it can be time-consuming and error-prone when done manually.

- Maintaining compliance: Staying up to date with ever-changing regulations and industry standards while ensuring fleet-wide compliance is a complex and ongoing challenge. Balancing the need for vehicle uptime with regulatory requirements often necessitates careful planning and resource allocation.

- Managing parts inventory: Finding the right balance between having necessary parts on hand and avoiding excessive inventory costs can be difficult. Insufficient stock can lead to costly downtime, while excessive inventory ties up capital.

- Unplanned downtime and breakdowns: Even with regular upkeep, unexpected failures will happen. These emergency situations disrupt schedules and test your crisis management abilities.

- Driver communication and accountability: Your maintenance program only works if drivers report issues promptly and accurately, and getting busy drivers to complete thorough pre-tip inspections and communicate with vehicles takes consistent training.

- Data overload: Modern telematics systems generate a lot of data. Sorting through those numbers to identify actionable business insights takes skill and time.

- Adapting to new technologies: The fleet industry is ever-evolving. Electric vehicles, advanced driver assistance systems and connected vehicle technologies all come with new maintenance requirements and keeping your team trained to stay ahead is time-consuming.

Fleet maintenance best practices

The more vehicles you have to manage, the harder it is to track when each one is due for maintenance. These fleet maintenance best practices help you build an efficient and effective fleet maintenance policy so you can stay on top of things.

Create a vehicle maintenance policy

A written fleet maintenance policy means you have clear rules and expectations for your entire organization. The document should outline maintenance schedules, inspection procedures and accountability measures.

You can create this policy manually, or you can invest in fleet maintenance software like Geotab, which will manage everything from inspections to mileage tracking automatically.

Customize driving rules

Driving rules (such as idle time, restrictions on harsh braking and route optimization) can be tailored to suit the specific needs of your fleet. Implementing these rules helps reduce unnecessary wear and tear, saving both time and money on repairs.

Set diagnostic reminders

Regular diagnostic checks are crucial to catching potential issues before they become serious problems. Automated reminders for these checks ensure that no vehicle in your fleet is overlooked, helping to keep consistent maintenance schedules.

Maintain compliance

Complying with regulatory requirements is essential to avoiding fines and ensuring the health and safety of your vehicles. Regularly reviewing and updating your fleet’s compliance status helps prevent legal issues and maintain operational efficiency.

Leverage predictive analytics

Predictive analytics using powerful telematics tools takes you from reactive to proactive when it comes to maintenance.

Telematics systems monitor engine diagnostics, fuel consumption and real-time fleet performance maintenance KPIs so you know exactly when a vehicle is due for maintenance. You can use historical data to analyze patterns and anticipate failures before they come.

Run reports regularly

Generating and analyzing reports on your fleet’s performance can provide valuable insights into areas needing improvement. Regular reports help you track maintenance trends, fuel usage and overall vehicle health, enabling data-driven decisions.

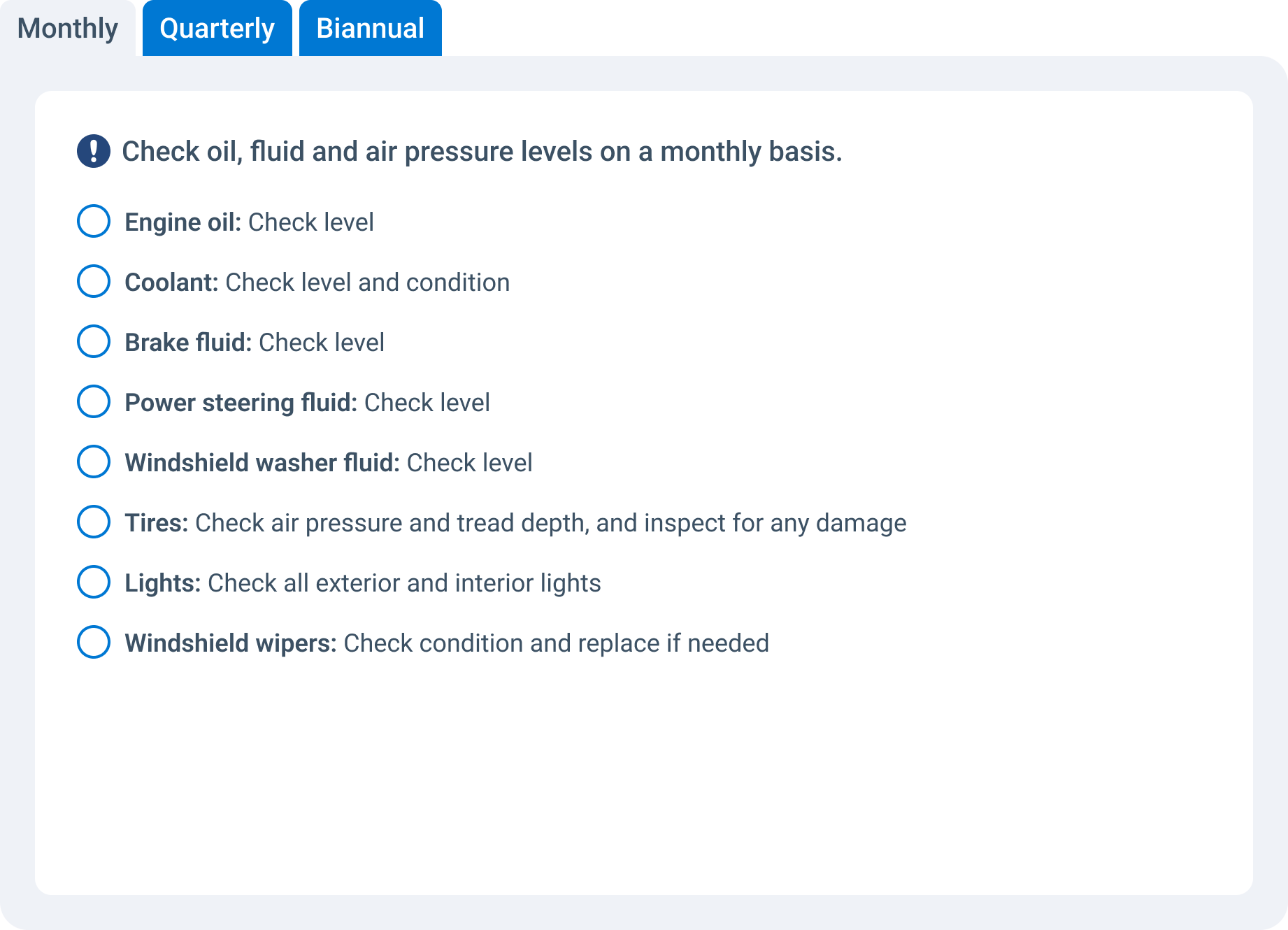

Fleet maintenance checklist

With the right fleet vehicle maintenance checklist template, you can mitigate many maintenance challenges. A well structured program should include a combination of routine inspections, fluid checks and component replacements.

Follow this checklist to avoid costly fixes and ensure you don’t miss any important routine inspections.

Automate maintenance with fleet management software

Fleet maintenance is crucial for maintaining an efficient and safe fleet, but balancing scheduling, data and tracking can be difficult. Adding a telematics solution to your fleet, like the Geotab platform, can help you stay on top of reminders and predictive maintenance to increase vehicle uptime and decrease costs.

Fleet maintenance isn’t just about fixing vehicles — it’s about building a foundation for operational success. Are you ready to transform your vehicle maintenance tracking? Explore Geotab’s solutions to learn how predictive analysis and automated scheduling can keep you ahead of the game at all times.

Subscribe to get industry tips and insights

Frequently Asked Questions

Fleet management is the process of managing fleet operations as a whole, while fleet maintenance focuses specifically on managing maintenance needs. For instance, common fleet management policies and procedures include route planning, driver management and vehicle tracking, while fleet maintenance covers vehicle inspections, repairs and parts management.

A fleet maintenance manager is responsible for the maintenance and upkeep of fleet vehicles. This includes creating a fleet maintenance schedule, managing inspection requirements, tracking vehicle data and training drivers.

Fleet services involve a wide range of duties for the management of fleet vehicles. Maintenance, vehicle selection and operations are some of the core components of fleet services.

Drivers play an important role in pre- and post-trip inspections. While fleet maintenance managers implement processes, it’s the driver’s job to identify potential issues and report them before minor problems become major.

Fleet maintenance reduces costs by catching minor issues before they become expensive repairs. Well maintained vehicles operate more efficiently, consuming less fuel and reducing per-mile costs. Regular maintenance also maintains vehicle life, maximizing your ROI.

Ben Schwartz is a Partner Account Manager for Geotab and author of the white paper Driver Safety Scorecards.

Table of Contents

Subscribe to get industry tips and insights

Related posts

How to stop wasting mechanic hours on ‘ghost codes’ and low-priority repairs

February 2, 2026

2 minute read

.jpg)

Go beyond reactive truck maintenance with predictive solutions that drive profits

December 8, 2025

3 minute read

Protecting Our Most Precious Cargo: How Telematics is Powering a Safer Ride to School

October 23, 2025

2 minute read

The top five benefits of intelligent police fleet maintenance

August 21, 2025

5 minute read

Your ultimate back to school bus fleet operations checklist

August 6, 2025

4 minute read