Autonomous trucking: The impact of self-driving trucks in the freight industry + guide

Learn what autonomous trucking is, why it matters, who’s leading the way and how your fleet can get ready.

By Phil Bugdahn

Jul 30, 2025

Key Insights

- Autonomous trucking refers to self-driving trucks that use sensors, AI and connectivity to operate with little or no human input.

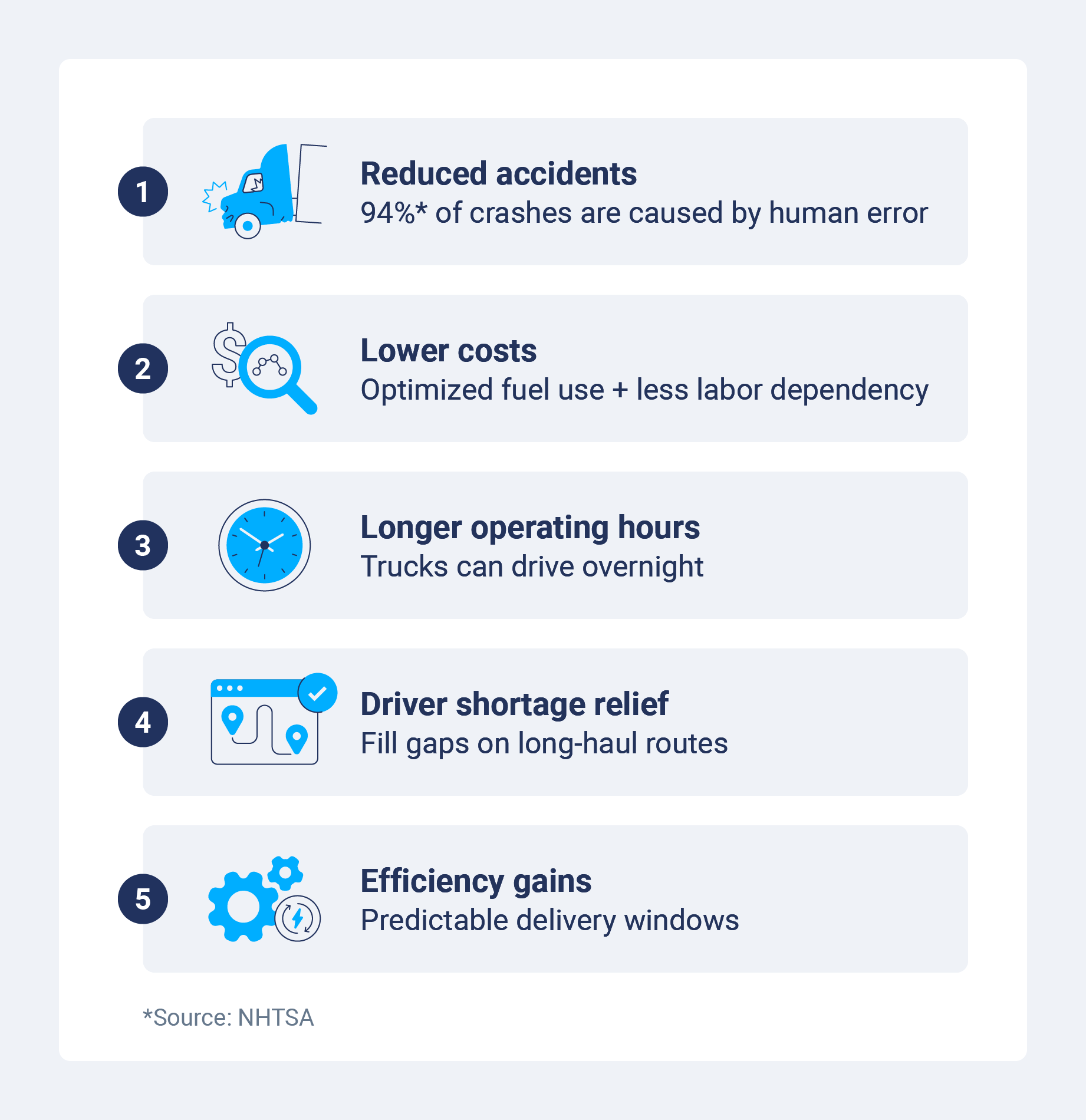

- It offers major benefits such as reduced accidents, lower operating costs, longer driving hours and a solution to ongoing driver shortages.

- Geotab helps fleets prepare for autonomous trucking by offering real-time telematics, data insights and fleet optimization tools to support a smooth and safe transition.

The freight industry is under pressure. There aren’t enough drivers, delivery demand keeps growing and operating costs are rising. It’s getting harder to keep trucks moving and customers happy.

Luckily, there’s a solution: autonomous trucking. Self-driving trucks aren’t just a futuristic idea anymore — they’re already on highways, ports and test routes across the U.S. And with nearly 80,000 truck driver positions unfilled in the U.S. and 3 million globally, the timing couldn’t be better.

Learn what autonomous trucking really means, how it works, who’s leading the way and what it could mean for your fleet. We’ll also look at safety, costs and the real-world impact.

What is autonomous trucking?

Autonomous trucking refers to self-driving trucks that use sensors, cameras and software to drive with little or no human input. These trucks can stay in their lanes, monitor traffic, adjust speed and even brake or change lanes — all on their own.

Here’s how autonomous trucks differ from traditional ones:

- Self-driving trucks use radar, lidar and cameras to “see” the road.

- AI software makes real-time driving decisions.

- Some systems still have a human safety driver onboard; others do not.

- The focus is on long-distance highway driving, not city streets.

This technology is mainly being developed for freight and logistics, especially for heavy-duty electric vehicles moving goods between warehouses, ports and hubs.

How do autonomous trucks work?

Autonomous semi trucks use a mix of smart hardware and software to drive themselves. They can handle long highway routes with little to no human help.

Here's how the key systems work together:

- Sensors: These trucks use lidar, radar and dash cams to detect the road, other vehicles, signs and obstacles, even in low-visibility conditions.

- Software: Advanced fleet safety software processes sensor data and makes real-time driving decisions like braking, steering and lane changes.

- Connectivity: GPS and vehicle-to-everything (V2X) communication help trucks stay on route, avoid hazards and communicate with road infrastructure.

- Safety systems: Trucks include advanced driver-assistance systems (ADAS), emergency braking and human override features to step in if needed.

- Telematics: These systems send you real-time data for tracking, maintenance and route updates.

What about automation levels?

Autonomous trucks fall into different levels of automation, based on how much human input they need:

- Level 1-2: Basic features like cruise control and lane keeping (driver still required)

- Level 3-4: Can drive themselves in certain conditions, but may still need a human in specific scenarios

- Level 5: Fully driverless in all conditions — not yet in use

Right now, most autonomous semi trucks on the road are between Level 2 and Level 4, with a human still monitoring from inside or remotely.

Use cases of autonomous trucks

Autonomous commercial vehicles are already being tested or used in specific freight and logistics scenarios. Here are some real-world examples:

- Long-haul highway routes between distribution centers

- Port-to-warehouse delivery with repeatable routes

- Overnight shipping to avoid traffic and reduce delays

- Yard operations for moving trailers without a driver

- Pilot runs with safety drivers on board for testing routes

These use cases help improve delivery times, reduce fuel costs and ease the pressure from ongoing driver shortages.

Why self-driving trucks?

Investing in a self-driving freight truck can help your fleet run safer, longer and more efficiently. Autonomous trucks are designed to solve major industry challenges, from driver shortages to rising costs. Here are the biggest benefits.

Potential for reduced incidents

Most road incidents are caused by human error, like speeding, distractions and fatigue. Self-driving freight trucks don’t get tired or lose focus. With built-in sensors and real-time decision-making, autonomous trucks can detect hazards faster and respond more consistently.

They also follow safe driving rules by default, such as maintaining distance, staying in lanes and adjusting speed. This could lead to fewer collisions, lower insurance costs and better safety records across your fleet.

Lower operating costs

Drivers are one of the largest ongoing costs. With autonomous trucks, you can reduce labor expenses over time, especially for long, repetitive routes that don’t require full-time attention.

Plus, self-driving freight trucks can optimize speed, braking and fuel use better than humans. This means lower fuel costs, less wear and tear and more predictable maintenance schedules.

Longer operating hours

Human drivers need breaks, sleep and shifts — for good reason. But autonomous trucks don’t face the same limits. Once approved, they could operate for longer stretches, even overnight, without rest.

This opens up new scheduling options and faster delivery windows, especially on long-haul routes where timing matters.

Help with driver shortages

The trucking industry is short tens of thousands of drivers, and the gap is growing. Our trucking industry statistics show that global driver shortages will double by 2028. Self-driving freight trucks can help fill that gap, especially for tough-to-staff overnight or long-distance runs.

The goal isn’t to replace drivers entirely. It’s to let people focus on higher-value, more complex tasks, while automation handles the repeatable, highway-heavy routes.

Long-haul freight delivery efficiency

Autonomous trucks are built for long hauls. With no need to stop for rest and fewer risks of delay, they’re ideal for cross-country or regional freight routes.

They can also reduce idle time at warehouses and use telematics to avoid traffic and adjust routes in real time. This gives you better fuel efficiency and faster delivery without overworking your team.

The big players in autonomous trucks

Several major companies (even the U.S. military!) are investing in self-driving electric semi trucks. These players are pushing the boundaries of what’s possible in automation, AI and fleet management. Let’s take a look at who’s leading the charge.

Daimler

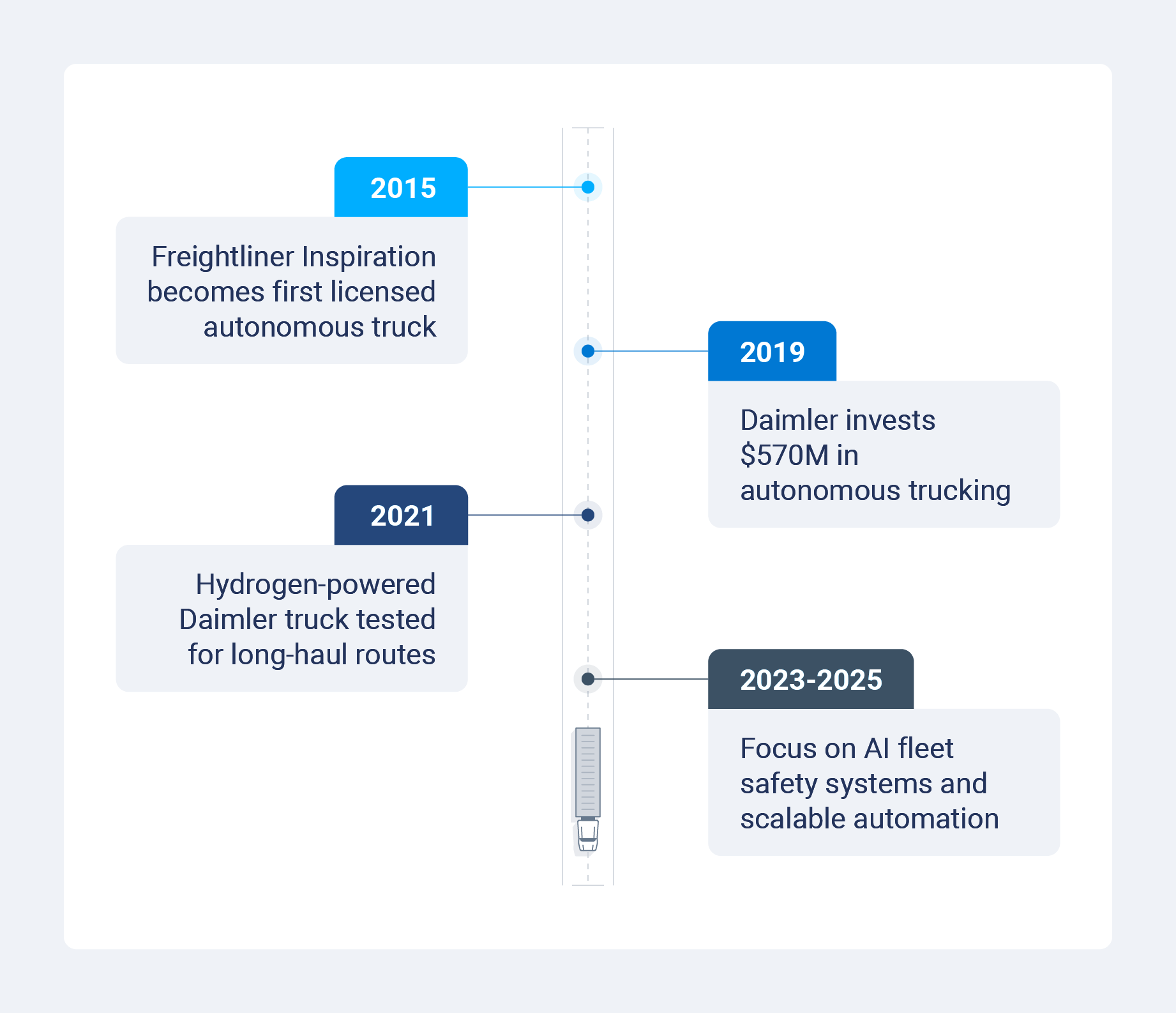

Daimler was an early mover. Back in 2015, it introduced the Freightliner Inspiration — the first autonomous truck licensed to operate on U.S. highways. It could stay in its lane and handle highway driving, but it still needed a human for things like passing, exits and city streets.

Daimler continues to improve its tech with a focus on long-haul freight and safety systems, including advanced AI fleet management tools.

Volvo

Volvo is exploring both highway automation and real-world use cases like autonomous garbage trucks. It’s leading research in truck platooning, where trucks follow each other closely to reduce drag and improve fuel efficiency.

Volvo has run tests in Sweden and the U.S., partnering with startups like Peloton Technology to test these connected systems in city and highway environments.

Tesla

Tesla shook up the industry with the reveal of its self-driving electric semi trucks, the Tesla Semi. It boasts a 500-mile range, fast acceleration and a sleek aerodynamic design.

Tesla plans to power these trucks using solar-charged megachargers, although that infrastructure is still in progress. With robotaxis already rolling in Austin, TX, Tesla continues to improve its Autopilot and Full Self-Driving (FSD) systems for both cars and trucks.

U.S. military

The U.S. military sees big potential in autonomous convoys and has placed an order for autonomy-ready heavy tactical vehicles worth $95 million. Its goal is to reduce risk to soldiers and improve supply delivery in combat zones.

Self-driving military trucks are being tested on rough terrain, narrow bridges and other battlefield-like environments. These convoys let soldiers stay in safer, more armored vehicles while still keeping supplies moving.

Aurora

Aurora, which acquired Uber’s self-driving truck division, is now a major force in this space. The company is developing autonomous technology specifically for freight and long-haul trucking.

Aurora’s trucks are already running test routes in Texas, and the company is working with key partners to make self-driving freight safer, more scalable and commercially viable.

Considerations and challenges of self-driving semi trucks

While automated truck driving brings big benefits, it also comes with real challenges. Some are technical, others are legal or social, but all will shape how fast and far self-driving trucks go.

Here are the key concerns:

- Safety and reliability: Even with advanced sensors and AI, these systems must prove they can handle unexpected situations, weather and human drivers around them.

- Public perception and trust: Many people are still unsure about sharing the road with driverless trucks. One accident can quickly set back progress and public confidence.

- Labor implications: Self-driving trucks may reduce the need for drivers on certain routes. This raises concerns about job losses, retraining and what roles humans will play moving forward.

- Regulations and insurance: Laws vary by state, and there’s no nationwide standard for autonomous trucking yet. Insurers are also figuring out how to cover these vehicles.

- Rural vs. urban deployment: Most test routes today focus on highways and open roads. Tight city streets, busy loading docks and rural areas add layers of complexity.

- Cybersecurity risks: Like any connected tech, autonomous trucks could be vulnerable to hacking. Protecting vehicle data and systems is a major priority.

- Infrastructure requirements: Smooth roads, smart signage and charging stations, especially for self-driving electric semi trucks, are all needed.

The future of self-driving semi trucks

The future of transportation is moving fast, and self-driving semi trucks are a big part of it. While full adoption is still years away, we’re already seeing real progress. Experts expect the first widespread use to happen on highway-only routes, where traffic is more predictable and easier to automate.

Still, there are big hurdles to clear. Legal regulations, tech limitations, high development costs and public trust all stand in the way. There are also ethical questions, like who’s responsible in an accident caused by an automated truck.

But this shift doesn’t mean pushing drivers out. Instead, it opens new roles. Existing truck drivers could transition into jobs that involve remote monitoring, managing autonomous operations or handling vehicle maintenance.

Are self-driving semi trucks the new normal?

Self-driving semi trucks aren’t fully replacing human-driven fleets any time soon, but they’re already being tested and slowly rolled out on select routes. The shift will likely be gradual, starting with highway automation and expanding as the technology and infrastructure mature.

If you’re thinking about preparing your fleet, here are a few tips to get started:

- Start small: Focus on automating long-haul or repeatable routes first.

- Prioritize safety: Use video telematics and other systems to support safety during the transition.

- Invest in telematics: Data is key to optimizing routes and vehicle performance.

- Train your team: Prepare drivers and managers for new roles like remote monitoring.

- Stay informed: Keep up with local laws, pilot programs and tech updates.

Geotab can help your fleet prepare for the future. From real-time telematics to fleet optimization tools, our platform gives you the insights and data you need to manage emerging technology with confidence.

Subscribe to get industry tips and insights

Frequently Asked Questions

Yes, autonomous trucks are legal, but it depends on where you are. Several U.S. states allow autonomous trucks on public roads, including Texas, Arizona, California, Florida and Nevada. Laws vary by state, and some still require a human safety driver. Regulations are evolving, so it’s important to stay updated.

The cost of an autonomous truck can range from $300,000 to over $500,000, depending on the technology and features. While expensive upfront, these trucks may lower costs over time through fuel savings, fewer accidents and longer operating hours.

Yes, autonomous trucks can support green fleets by driving more efficiently, reducing idle time and optimizing routes. Some models are also electric, which lowers emissions even more.

Not completely. Autonomous trucks will likely handle specific routes — mainly highways — while humans take on local driving, oversight and remote support roles. Instead of replacing drivers, the industry is shifting toward new kinds of jobs that support automated operations.

Phil Bugdahn is an Internal Development Manager for Geotab.

Table of Contents

Subscribe to get industry tips and insights

Related posts

Building a coaching culture: How to end the ‘gotcha’ game in your fleet

March 4, 2026

3 minute read

How long do electric car batteries last? The updated guide to real-world EV battery health

January 12, 2026

10 minute read

Collision avoidance systems: How fleets prevent incidents and improve safety

December 23, 2025

5 minute read